Nozzle of airflow dyeing machine

An airflow dyeing machine and nozzle technology, which is applied to liquid/gas/vapor jet propulsion fabrics, textile processing machine accessories, and textile materials processing, etc., can solve problems such as slow cleaning effect, deviation of dye liquor jet, and uneven jetting. , to achieve the effect of uniform dye spraying, increasing fluid pressure and smooth dye spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

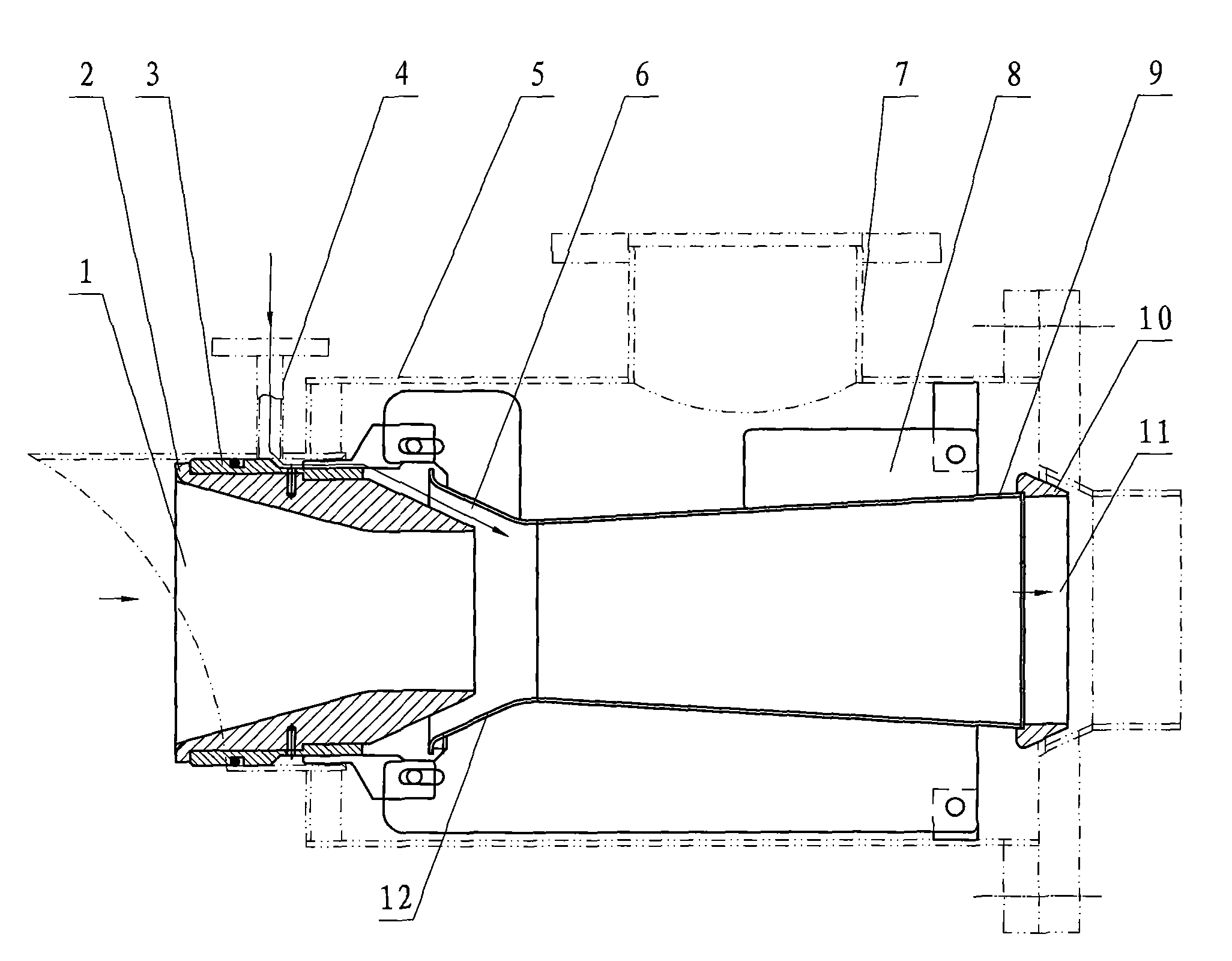

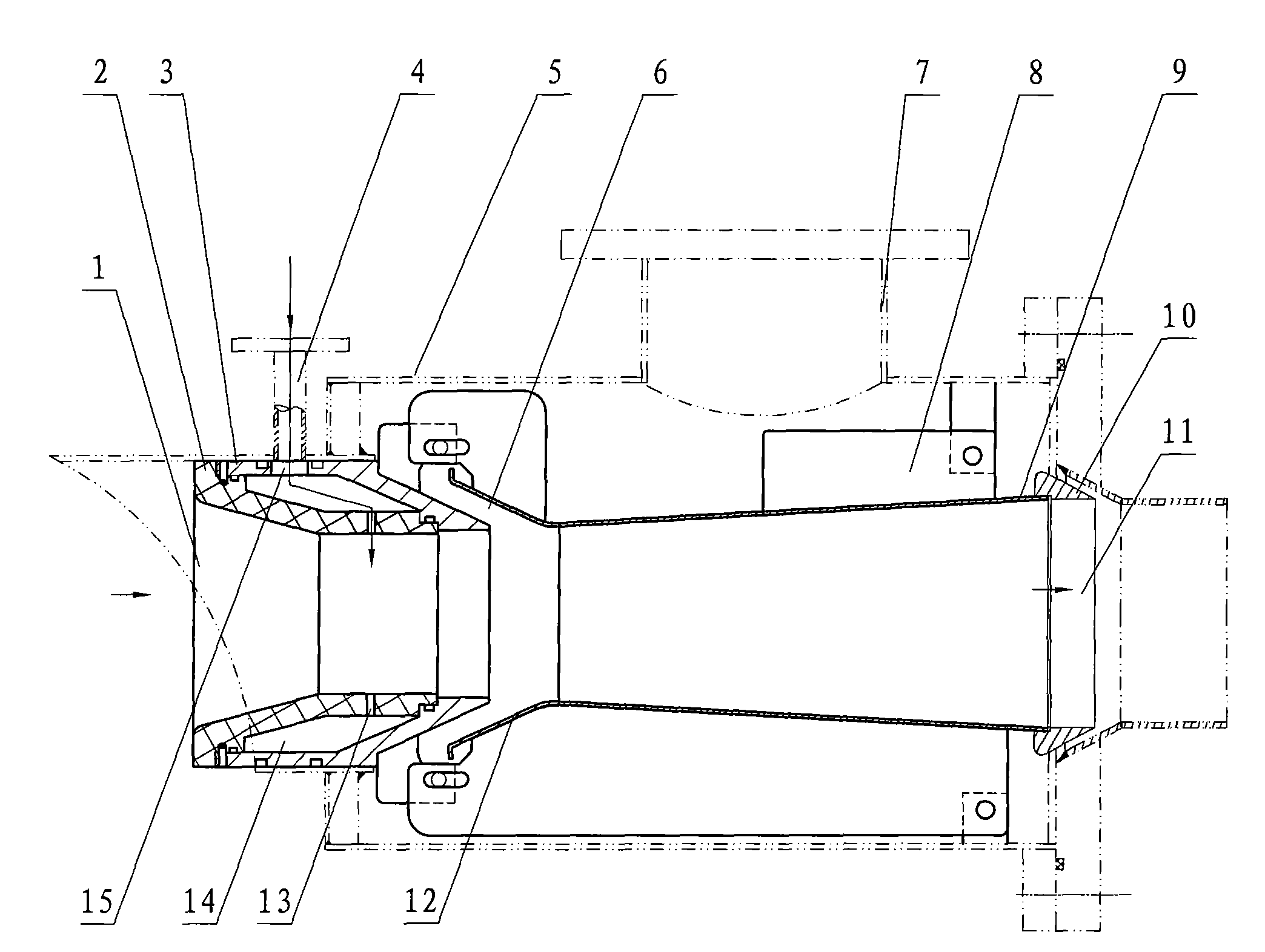

[0011] Such as figure 2 As shown, the present invention is a nozzle of an airflow dyeing machine. It includes a front nozzle cover 2 , a positioning sleeve 3 , a nozzle body 9 and a rear nozzle head 10 . The front end of the nozzle body 9 is provided with a front guide nozzle 12, and the front guide nozzle 12 is bell-shaped. The positioning sleeve 3 is set on the front nozzle cover 2 , and the positioning sleeve 3 is connected with the nozzle body 9 through the connecting piece 8 . The improvement of the present invention is that an air inlet 6 is provided between the rear end of the positioning sleeve 3 and the front guide nozzle 12, a dye solution chamber 14 is provided between the front nozzle cover 2 and the positioning sleeve 3, and the front nozzle cover 2 A dye solution outlet 13 is arranged on the top, and a dye solution inlet 15 is arranged on the positioning sleeve 3, and the dye solution outlet 13 and the dye solution inlet 15 communicate with the dye solution ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com