Roller extrusion type releasing and separating device and method for ramie

A separation equipment, extrusion technology, applied in drafting equipment, textiles and papermaking, spinning machines, etc., can solve the problems of large fiber damage, insufficient impact, and excessive residual colloid, and reduce the serious fiber entanglement and mutual interaction. Reduced entanglement and uniform release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

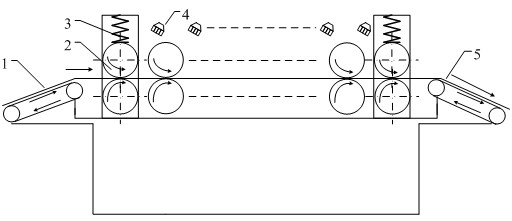

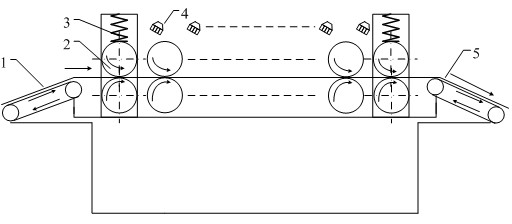

[0019] like figure 1 Shown is a schematic structural view of the roller extrusion type loosening and separating equipment for ramie, which includes a feeding curtain 1 and an output curtain 5, and 5 pairs of belts arranged in a straight line are arranged between the feeding curtain 1 and the output curtain 5. The roller 2 of the groove is provided with a pressurizing spring 3 on the upper side of the roller 2, the roller 2 is connected to the transmission device, and the top of the roller 2 is provided with a spray pipe 4. Roller 2 performs forward rotation and reverse rotation respectively under the action of the transmission device. In a reciprocating cycle of forward and reverse rotation, the forward length of the hemp handle is 200mm larger than the backward length. The direction of the water flow sprayed by the shower pipe 4 is opposite to the overall forward direction of the mop. The surface grooves of each pair of rollers 2 have the same helical direction, and the heli...

Embodiment 2

[0022] like figure 1 Shown is the structural schematic diagram of the roller extrusion type loosening and separating equipment for ramie, which includes a feeding curtain 1 and an output curtain 5, and 14 pairs of belts arranged in a straight line are arranged between the feeding curtain 1 and the output curtain 5. The roller 2 of the groove is provided with a pressurizing spring 3 on the upper side of the roller 2, the roller 2 is connected to the transmission device, and the top of the roller 2 is provided with a spray pipe 4. Roller 2 performs forward rotation and reverse rotation respectively under the action of the transmission device. In a reciprocating cycle of forward and reverse rotation, the forward length of the hemp handle is 800mm larger than the backward length. The direction of the water flow sprayed by the shower pipe 4 is opposite to the overall forward direction of the mop. The surface grooves of each pair of rollers 2 have the same helical direction, and th...

Embodiment 3

[0025] like figure 1 Shown is the structural schematic diagram of the roller extrusion type loosening and separating equipment for ramie, which includes a feeding curtain 1 and an output curtain 5, and 10 pairs of belts arranged in a straight shape are arranged between the feeding curtain 1 and the output curtain 5. The roller 2 of the groove is provided with a pressurizing spring 3 on the upper side of the roller 2, the roller 2 is connected to the transmission device, and the top of the roller 2 is provided with a spray pipe 4. Roller 2 performs forward rotation and reverse rotation respectively under the action of the transmission device. In a reciprocating cycle of forward and reverse rotation, the forward length of the hemp handle is 400mm larger than the backward length. The direction of the water flow sprayed by the shower pipe 4 is opposite to the overall forward direction of the mop. The surface grooves of each pair of rollers 2 have the same helical direction, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com