Printing and dyeing drip machine

A technology of dripping machine and mother liquor, applied in the field of textile dyeing and finishing, can solve the problem that the dripping machine does not have the functions of foaming and stirring, and achieves the effect of reducing time, reducing space and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

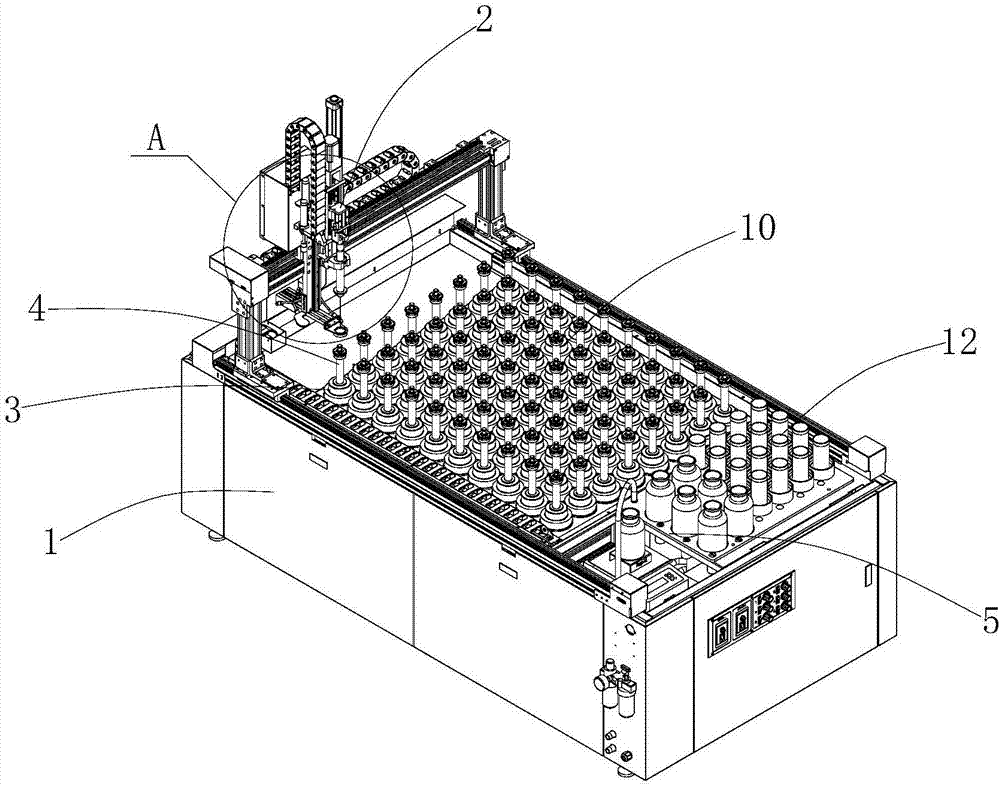

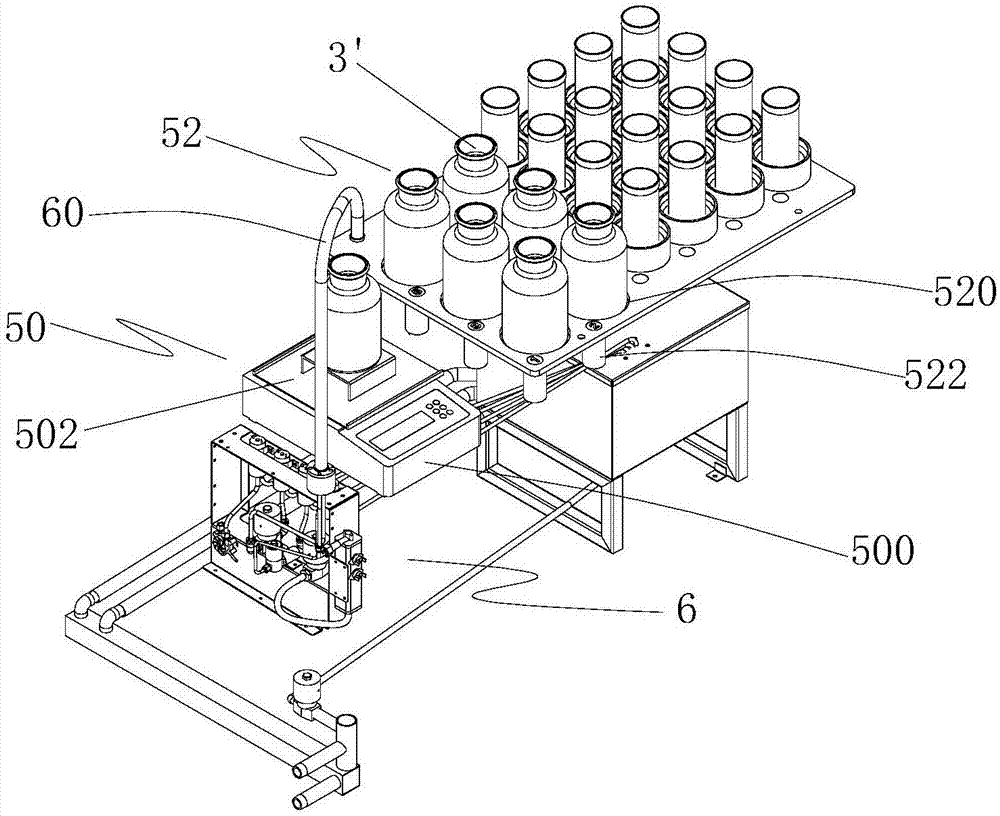

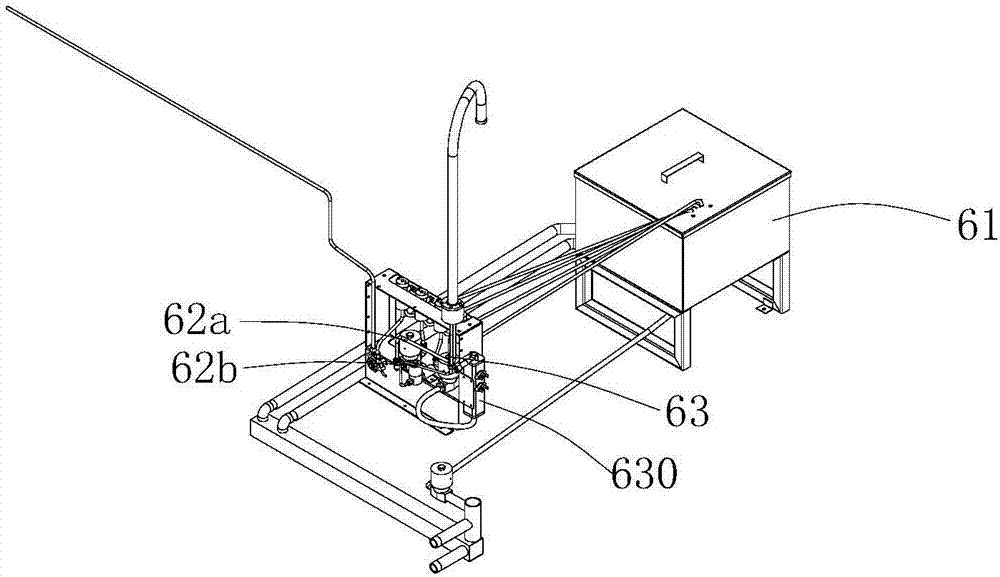

[0027] Such as figure 1 with figure 2 As shown, the present invention provides a printing and dyeing dripping machine, which includes a machine table 1 with a liquid taking area 10 for placing mother liquor bottles and a liquid dispensing area 12 for placing dye cups. A three-axis manipulator 2 is arranged above the liquid area, and the manipulator cooperates with the syringe to transfer the mother liquid into the dye cup on the liquid preparation area and insert the syringe back into the corresponding mother liquid bottle. reference figure 1 , There are multiple mother liquid bottles 3 in multiple rows and multiple columns in the liquid taking area 10, and each mother liquid bottle 3 is equipped with a syringe 4, so there is no need to clean the liquid when dispensing, and the dripping speed is very fast. The robot automatically according to the control center The instructions need to move the syringe automatically; the liquid dispensing operation is also instructed by the con...

Embodiment 2

[0034] reference Figure 4 with Figure 5 The structure of the dripping machine in this embodiment and the printing and dyeing dripping machine described in Embodiment 1 are roughly the same. The difference is that the robot 2 is also provided with a drip pan 7 under the syringe 4 that is clamped. There is a liquid receiving groove 70 on the top surface of the liquid receiving pan, and the liquid receiving pan is fixed to the manipulator by a telescopic mechanism 8 which can move synchronously with the manipulator and can make a telescopic movement in the horizontal direction. reference Figure 4 The telescopic mechanism includes a track 80, a slider 82 located on the track, and an air cylinder 84. The wetted pan 7 is fixed to the slider by a wetted pan fixing member 86, so that the air cylinder can control the horizontal telescopic movement of the wetted pan .

[0035] When the manipulator grips the syringe from the mother liquid bottle, the drip tray is retracted to provide sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com