Sizing machine

A sizing machine and sizing technology, which is used in textile processing machine accessories, liquid/gas/vapor removal with squeeze rollers, and processing of textile materials, etc., can solve the problems of applying sizing, difficult sizing to supply bottom coating rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

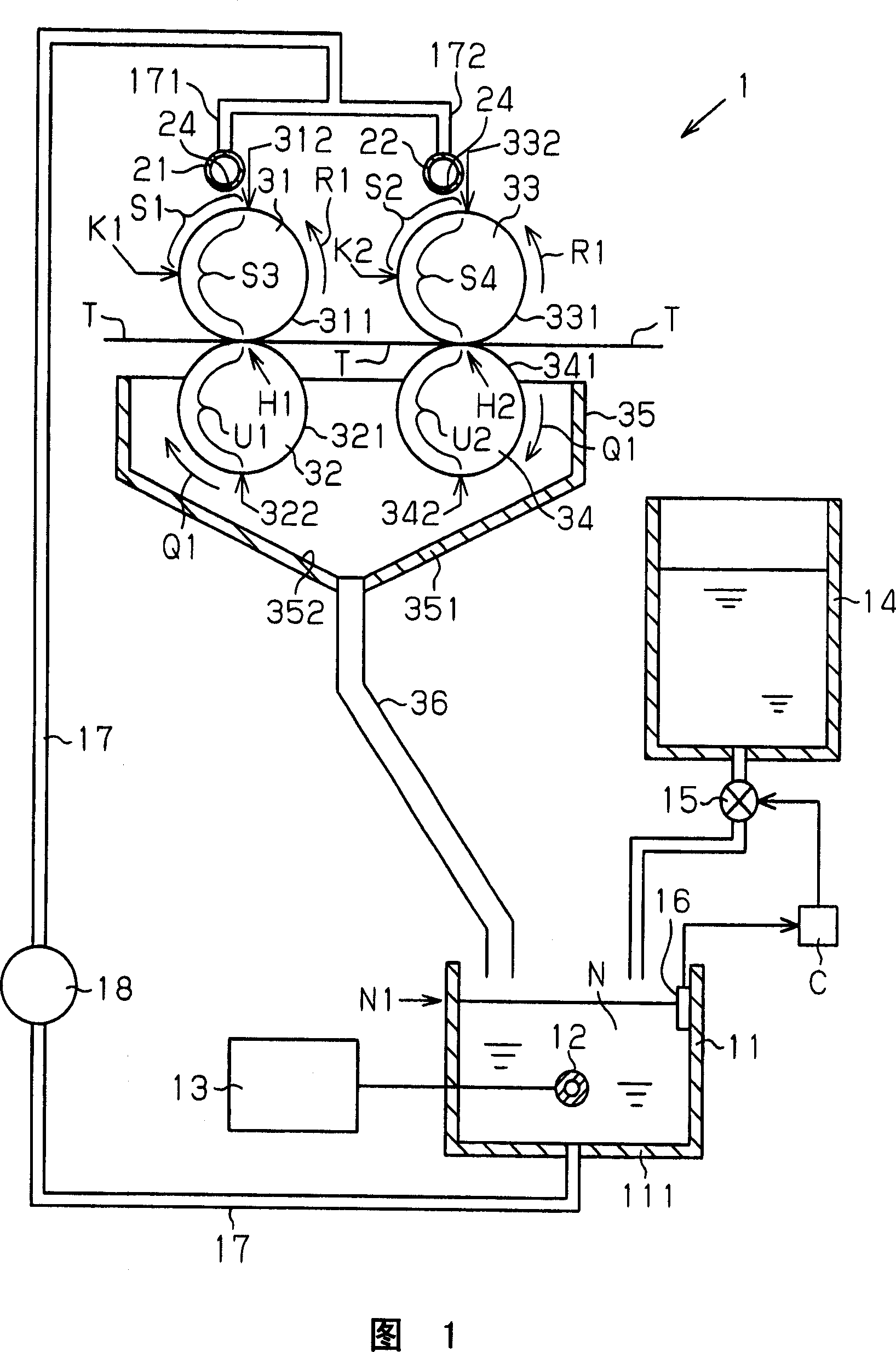

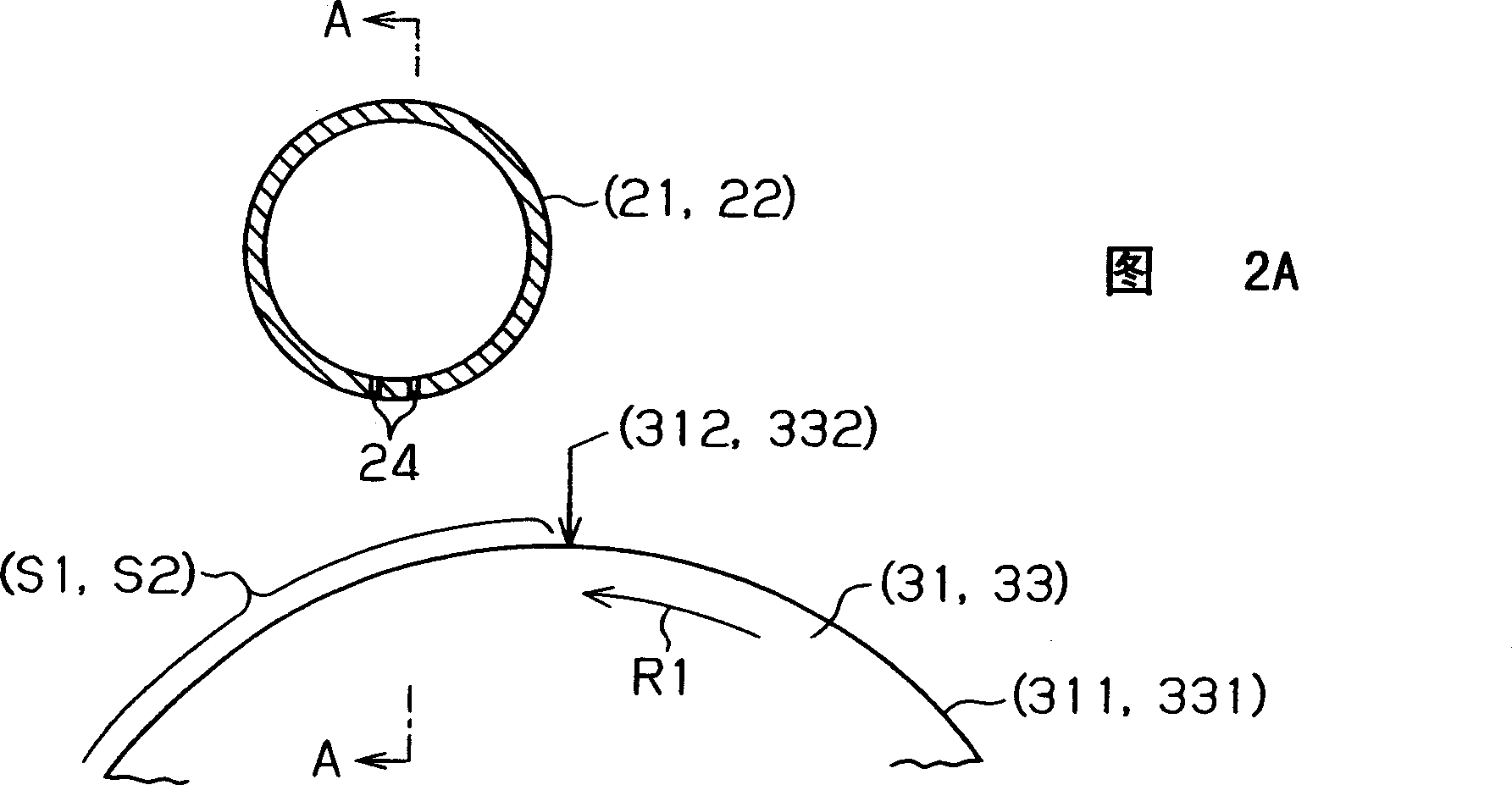

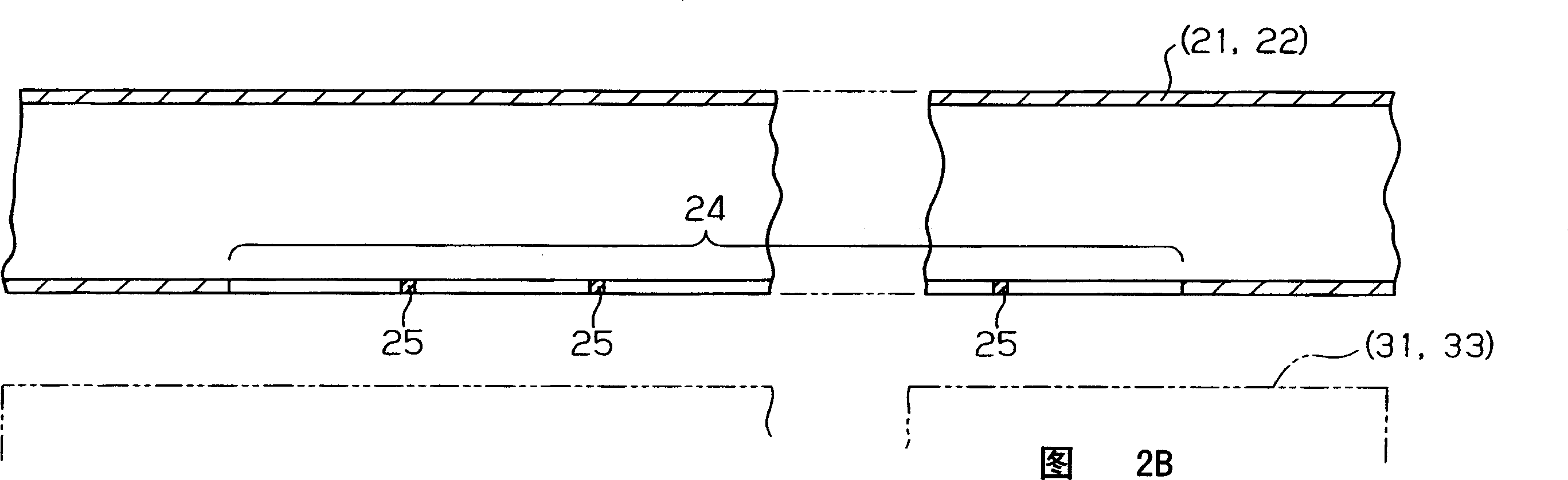

[0012] An embodiment of the present invention will now be described with reference to the accompanying drawings 1-3. First, the sizing machine 1 is introduced.

[0013] As shown in FIG. 1 , the sizing machine 1 has a size tank 11 for temporarily storing the size liquid N. As shown in FIG. The heating pipe 12 is located in the slurry tank 11 . Steam of a predetermined temperature is supplied into the inside of the heating pipe 12 from a steam supply source 13 . The steam supplied to the inside of the heating pipe 12 heats the slurry N in the slurry tank 11 so that the slurry N does not harden. The quantity and temperature of the steam supplied from the steam supply source 13 to the heating pipe 12 are adjusted so that the temperature of the slurry N in the slurry tank 11 is within a desired temperature range, such as between 90-95° C. inclusive.

[0014] The slurry tank 11 is connected to a slurry supply source 14 which stores slurry N to be supplied to the slurry tank 11 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com