Vertical winding type continuous chemical silver-plating method and device for flexible fabric

A technology of chemical silver plating and flexible fabrics, applied in the field of chemical plating, can solve the problems of low production efficiency, inconvenient stretching, and affecting the appearance, and achieve the effects of excellent washability, bright and dense silver layer, no partial plating and color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Base material: polyester mesh, weight 26.5 / m 2 , thickness 0.12mm, width 1.6m, roll length 150m.

[0042] Treatment process: sensitization-cleaning 2 times, each 3min; pre-plating-cleaning 1, 3min; ultrasonic-assisted chemical silver plating 30min-cleaning 2 times, each 5min; drying-inspection.

[0043] In the above process:

[0044] Sensitization treatment solution 300L: hydrochloric acid 10ml / L, stannous chloride 10g / L, room temperature, treatment time 30min.

[0045] Pre-plating solution 300L: silver nitrate 0.12g / L, ammonia water 0.20ml / L, room temperature, treatment time 5min.

[0046] Silver plating solution 500L: silver nitrate 2.86g / L, sodium hydroxide 0.025g / L, ammonia water 2.75ml / L, sodium EDTA2 0.42g / L, reducing agent formaldehyde 3.27ml / L, temperature 50℃, treatment time 60min; ultrasonic Frequency 28kHZ.

[0047] Drying: hot air circulation air drying, drying temperature 100 ℃, drying time 30min.

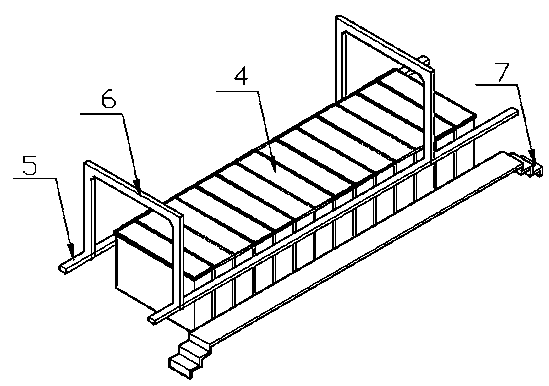

[0048]After the winding support device is placed in t...

Embodiment 2

[0051] Base material: polyester mesh, weight 30.5 / m 2 , thickness 0.12mm, width 1.5m, roll length 200m.

[0052] Treatment process: sensitization-cleaning 2 times, each 3min; pre-plating-cleaning 1, 3min; ultrasonic-assisted chemical silver plating 30min-cleaning 2 times, each 5min; drying-inspection.

[0053] In the above process:

[0054] For sensitization, 280L of sensitization treatment solution is used for 90 minutes at room temperature, and the concentration of each component is: hydrochloric acid 50ml / L, stannous chloride 30g / L; during the treatment process, a quantitative supplementary pump is used to continuously add sensitization solution and replenishment solution 20L, the concentration of each component is: hydrochloric acid 90ml / L, stannous chloride 60g / L, and the balance is pure water;

[0055] Pre-plating is treated with 300L pre-plating bath at room temperature for 30 minutes, the concentration of each component is: silver nitrate 1g / L, ammonia water 2ml / L, a...

Embodiment 3

[0061] Base material: polyester mesh, weight 20 / m 2 , thickness 0.12mm, width 1.6m, roll length 20m.

[0062] Treatment process: sensitization-cleaning 2 times, each 3min; pre-plating-cleaning 1, 3min; ultrasonic-assisted chemical silver plating 30min-cleaning 2 times, each 5min; drying-inspection.

[0063] In the above process:

[0064] For sensitization, use 290L of sensitization treatment solution at room temperature for 10 minutes, and the concentration of each component is: hydrochloric acid 10ml / L, stannous chloride 10g / L; during the treatment process, use a quantitative supplementary pump to continuously add sensitization solution and replenishment solution 20L, the concentration of each component is: hydrochloric acid 30ml / L, stannous chloride 30g / L, and the balance is pure water;

[0065] Pre-plating is treated with 280L pre-plating solution at room temperature for 5 minutes, and the concentration of each component is: silver nitrate 0.1g / L, ammonia water 0.2ml / L; d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com