Humidifying method of acetate fibre and humidifying device of acetate fibre

A technology of humidification equipment and acetate fiber, which is applied in the field of acetate fiber humidification and its humidification equipment, can solve the problems of impact reduction and reduction, and achieve the effects of reducing load, reducing damage and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

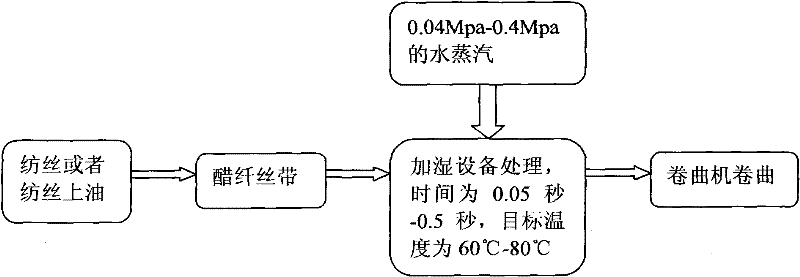

Method used

Image

Examples

Embodiment 1

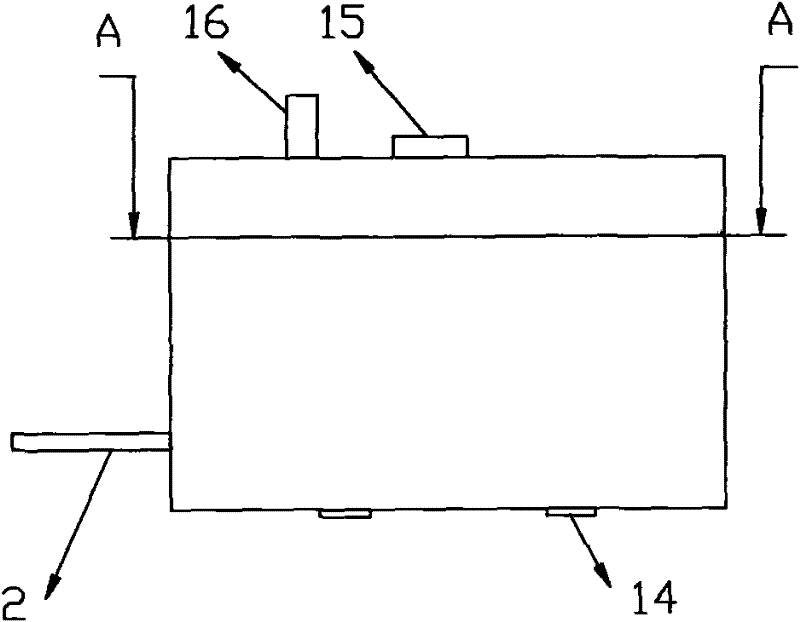

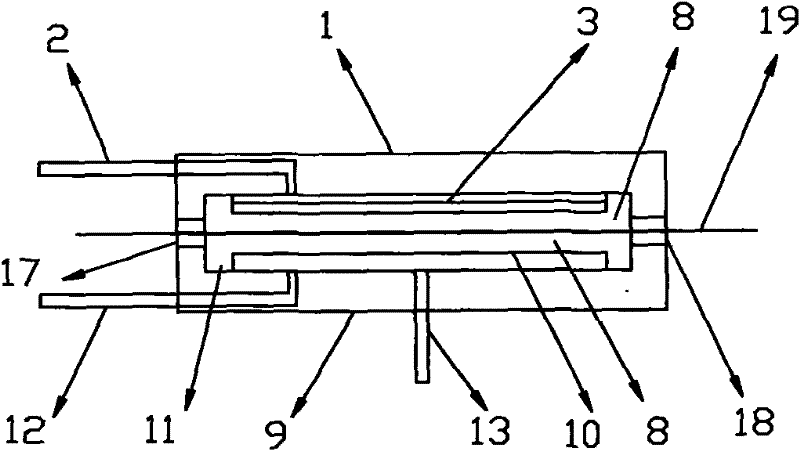

[0031] The upper steam injection orifice 3 is inclined, the connection line between the lower end 4 of the upper orifice and the upper end 5 of the upper orifice is at an angle of 15° to the horizontal plane, and the position of the condensed water tank 11 is lower than the lower steam injection orifice 10. 10mm. The upper steam injection orifice plate 3 and the lower steam injection orifice plate 10 are made of stainless steel, and the upper steam injection orifice plate 3 and the lower steam injection orifice plate 10 respectively contain 60 injection holes 6 with a diameter of 1mm-3mm. The upper part 1 of the humidifying box and the lower part 9 of the humidifying box are connected on one side by a hinge 14, and the other side of the upper part 1 of the humidifying box also includes a handle 15 for easy opening and closing. A temperature detection device 16 is also installed in the ribbon running chamber 7, and is connected with a flow meter or a regulating valve on the ste...

Embodiment 2

[0034]The upper steam injection orifice 3 is arched, the connection line between the lower end 4 of the upper orifice and the upper end 5 of the upper orifice is at an angle of 30° to the horizontal plane, and the position of the condensate water tank 11 is lower than the lower steam injection orifice 10. 25mm. The upper steam injection orifice plate 3 and the lower steam injection orifice plate 10 are made of stainless steel, and the upper steam injection orifice plate 3 and the lower steam injection orifice plate 10 respectively contain 100 injection holes 6 with a diameter of 1mm-3mm. The upper part 1 of the humidification box and the lower part 9 of the humidification box of the humidification device contain insulation layers to ensure the stability of the steam temperature; holes or hardware parts for easy installation are reserved on the shell of the humidification device. The steam chamber 8 is also equipped with a temperature detection device 16, which is connected wit...

Embodiment 3

[0037] The upper steam injection orifice 3 is inclined, the connection line between the lower end 4 of the upper orifice and the upper end 5 of the upper orifice is at an angle of 45° to the horizontal plane, and the position of the condensed water tank 11 is lower than the lower steam injection orifice 10. 50mm. The upper steam injection orifice plate 3 and the lower steam injection orifice plate 10 respectively contain 200 injection holes 6 with a diameter of 1mm-3mm. The upper part 1 of the humidifying box and the lower part 9 of the humidifying box are connected on one side by a hinge 14, and the other side of the upper part 1 of the humidifying box may also include a handle 15 for easy opening and closing. The upper part 1 of the humidification box and the lower part 9 of the humidification box of the humidification device contain insulation layers to ensure the stability of the steam temperature; holes or hardware parts for easy installation are reserved on the casing of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com