Production method of speck yarn

A production method and yarn technology, which is applied in the field of textile printing and dyeing, can solve the problems of low production efficiency and easy falling off of color dots, and achieve the effects of high production efficiency, not easy to fall off, and good comprehensive benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

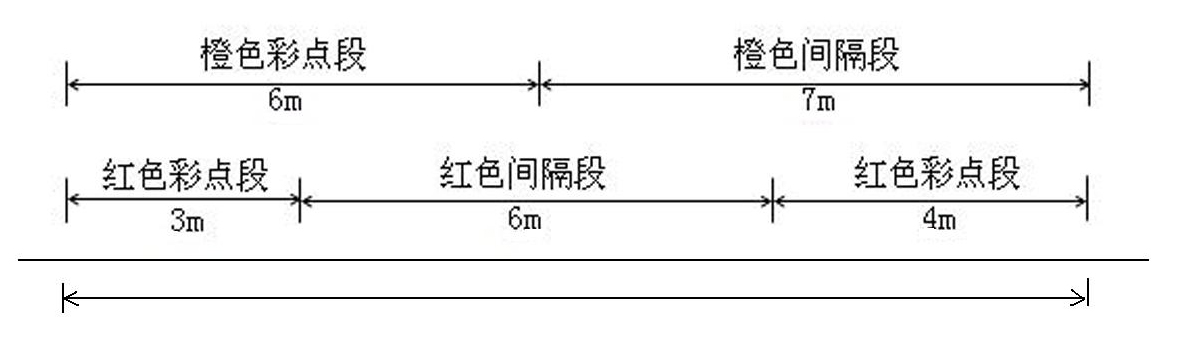

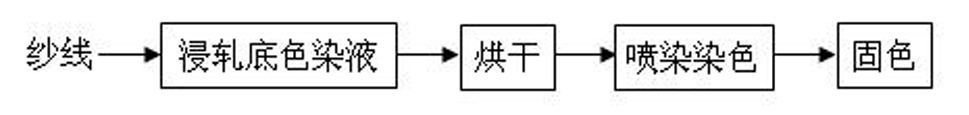

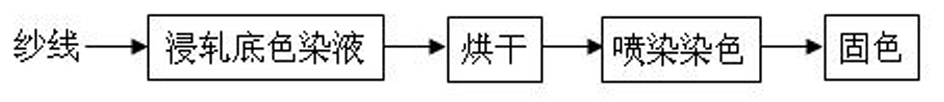

[0021] Now processed as figure 1 A kind of color dot sample yarn design shown, according to the technical scheme of the present invention, the yarn is made according to the following steps:

[0022] 1. will figure 1 A cycle formed by the color arrangement and combination of the color dots is determined as a color dot pattern cycle, and the length E of the color point pattern cycle is 13m;

[0023] 2. Set the color of the dyeing solution corresponding to the first nozzle and the second nozzle to orange and red respectively during spraying, and determine the length of the yarn in the spraying state of the first nozzle when the yarn passes through the first nozzle A. The yarn travel length B in the intermittent state of the first nozzle, and the value of the frequency-speed ratio D, where the value of the frequency-speed ratio D is obtained by selecting multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com