Pressurized steam drawing machine for drawing fibers

A drafting device and water vapor technology, which is applied in the field of pressurized water vapor drafting device, can solve the problems of high drafting and uniform fineness of the original yarn, and achieve high orientation degree, high drafting ratio, and high guarantee. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

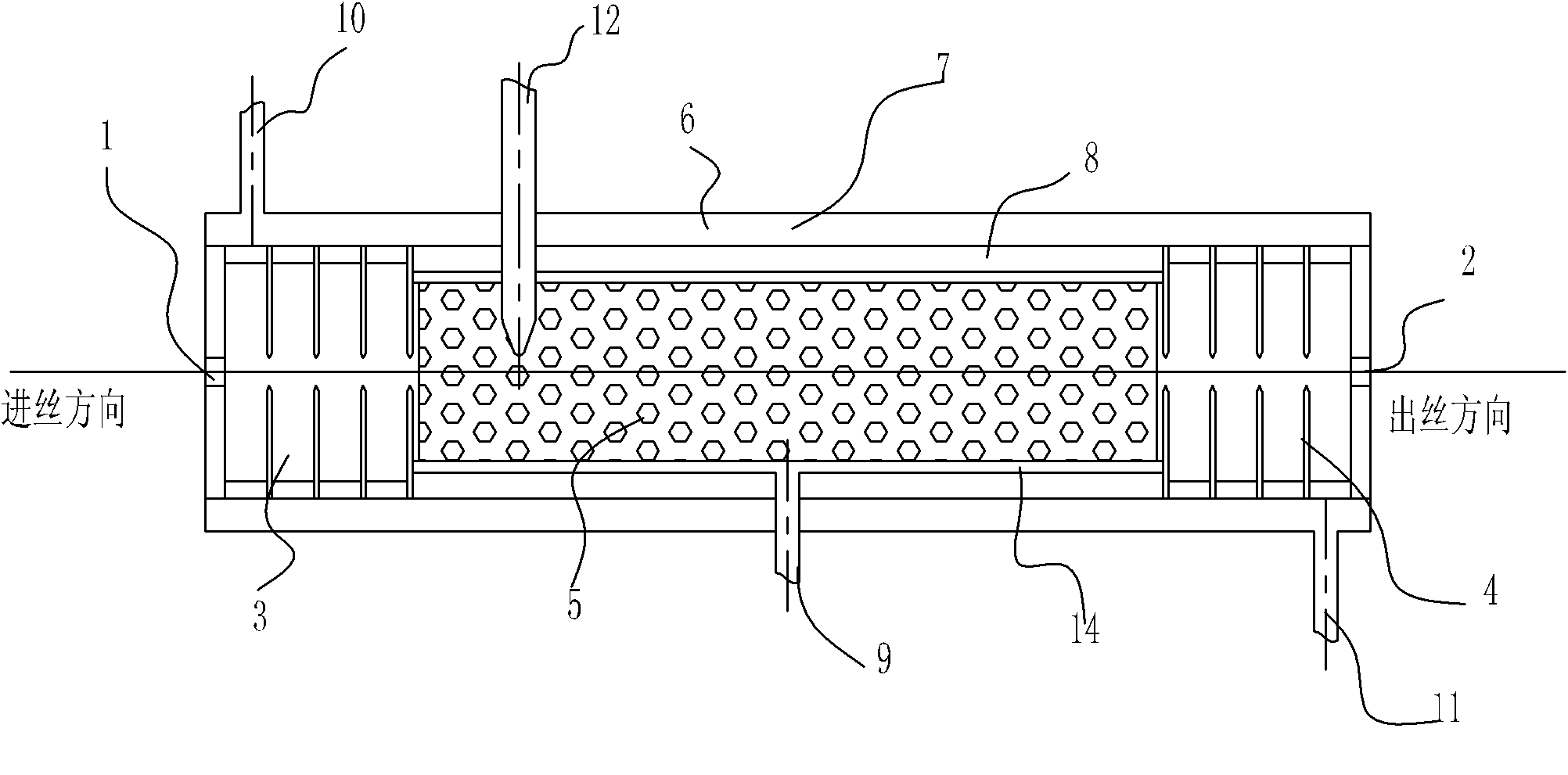

[0024] Such as figure 1 The result schematic diagram of the present invention is shown, a pressurized water vapor drafting device for fiber drafting, comprising a box 6, a tow inlet window 1 and a tow outlet window 2 arranged at both ends of the box body 6, 6, the inlet seal part 3 adjacent to the tow inlet window 1, the outlet seal part 4 arranged in the box and adjacent to the tow outlet window 2, and the outlet seal part arranged between the inlet seal part and the outlet seal part and located in the box The drafting chamber 5 is filled with porous materials. The box body includes a main body insulation layer 8 for maintaining the temperature in the drafting chamber and a pipeline insulation layer 7 for maintaining the temperature of the main body insulation layer. A steam chamber 14 is arranged between the layer 8 and the drafting chamber 5, and a water vapor pipe 9 connecting the steam chamber and an external water vapor source is arranged on the box body 6 . The pipelin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com