Liquid flow type skein dyeing machine

A skein dyeing machine, liquid flow technology, applied in the field of dyeing machines, can solve problems such as loose twist, dye spots, affecting product quality and pass rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A number of embodiments of the present invention will be disclosed below with the accompanying drawings. For the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the present invention, these practical details are unnecessary. In addition, for the sake of simplifying the drawings, some known and conventional structures and elements will be shown in a simple and schematic manner in the drawings.

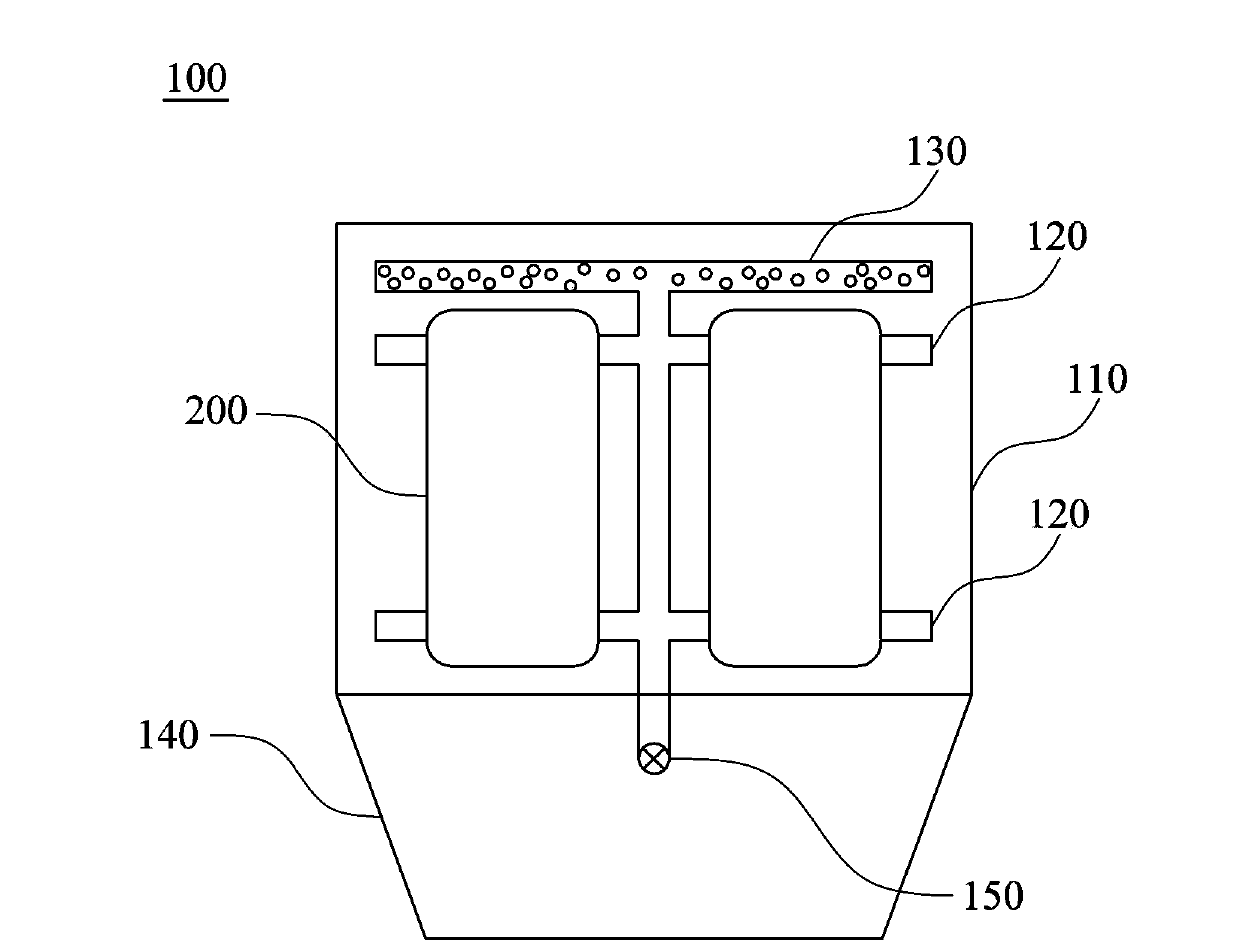

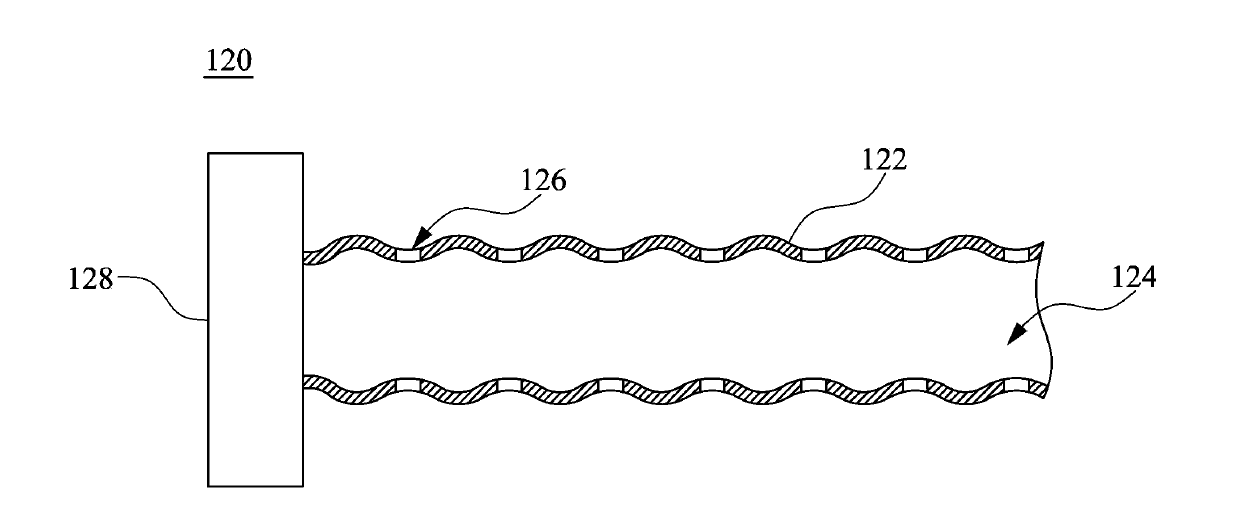

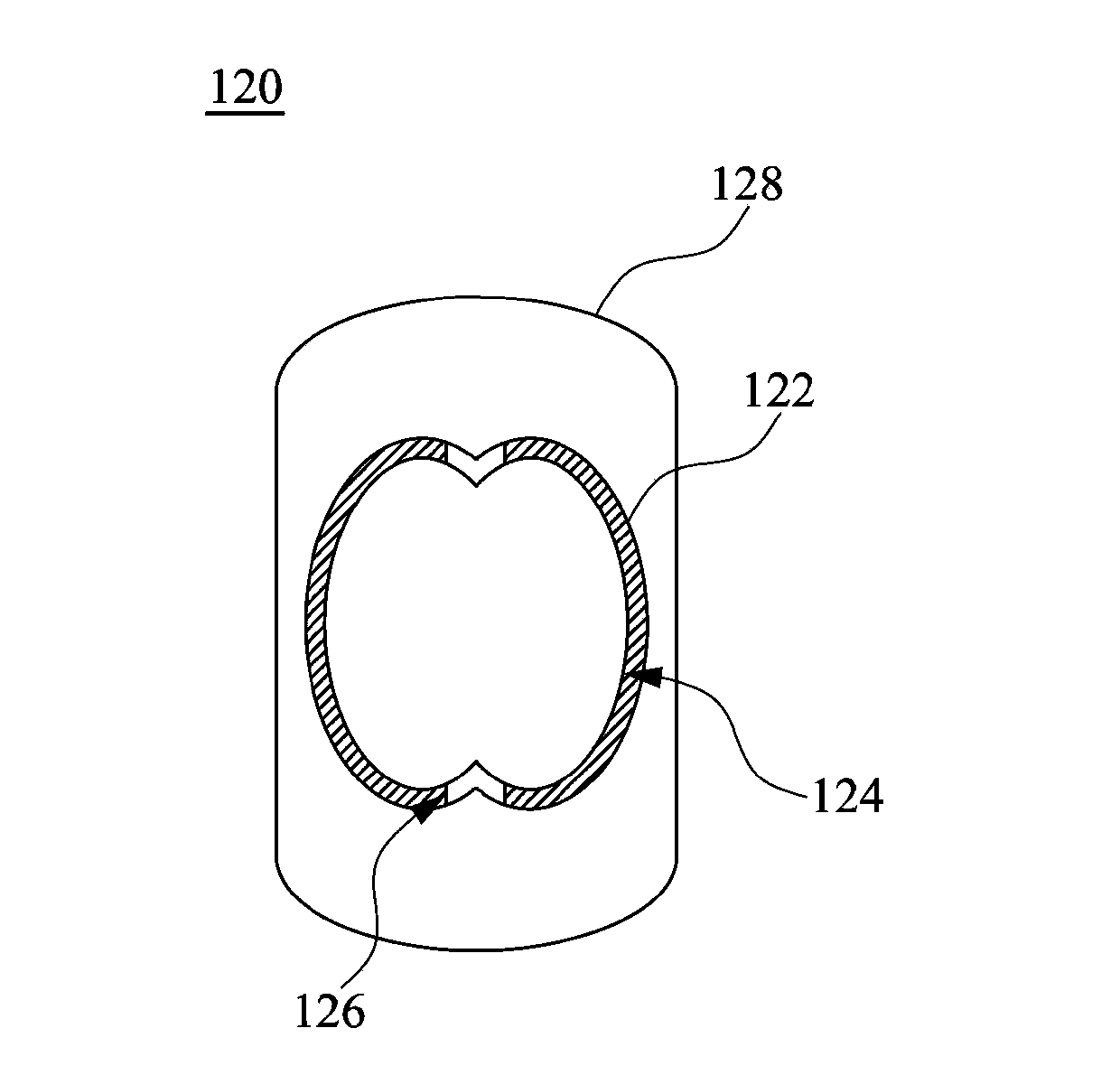

[0038] figure 1 A schematic front view of a liquid flow hank yarn dyeing machine 100 according to an embodiment of the present invention is shown. Such as figure 1 As shown, a liquid flow hank yarn dyeing machine 100 includes a vertical cylinder 110 , at least one pair of hank yarn fixing rods 120 , a spraying mechanism 130 , a dye liquor tank 140 and a liquid flow pump 150 . The skein fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com