Spinning head and method for preparing braided tube/polymer composite membrane by using spinning head

A braided tube and composite membrane technology, applied in chemical instruments and methods, textile material contact export textile material treatment, membrane technology, etc., can solve problems such as different uniformity, changes, and impact on membrane structure performance, to ensure thickness Consistency, enhanced binding force, and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following describes the present invention in detail with reference to the drawings and embodiments:

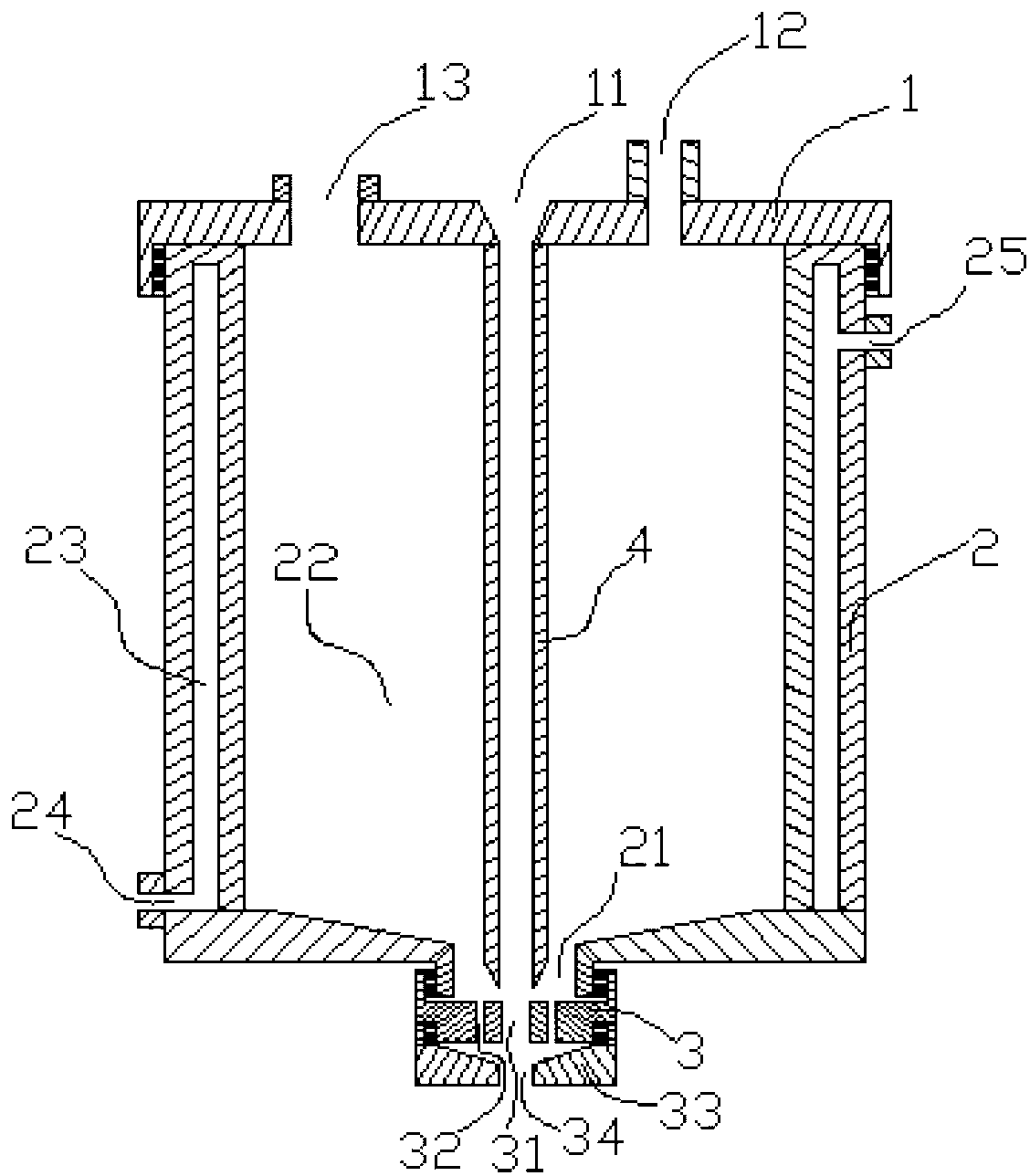

[0031] Such as figure 1 As shown, a spinning head for preparing a braided tube / polymer composite membrane includes a shell 2 and a cover plate 1 arranged on the top of the shell 2, wherein the cover plate 1 is provided with a fiber braided tube inlet 11 and a pressure hole 12 and the casting liquid inlet 13; the fiber braided pipe inlet 11 is connected with an inner duct 4 extending to the bottom of the housing 2; the housing 2 has a casting liquid outlet 21 at the bottom, and the casting liquid outlet 21 is connected with a spinneret 3; It is a double-layer drum structure, the inner drum forms a casting liquid cavity 22, the cavity between the outer drum and the inner drum forms a circulating bath heating cavity 23; the side walls of the outer drum are respectively opened There are a circulating bath inlet 24 and a circulating bath outlet 25.

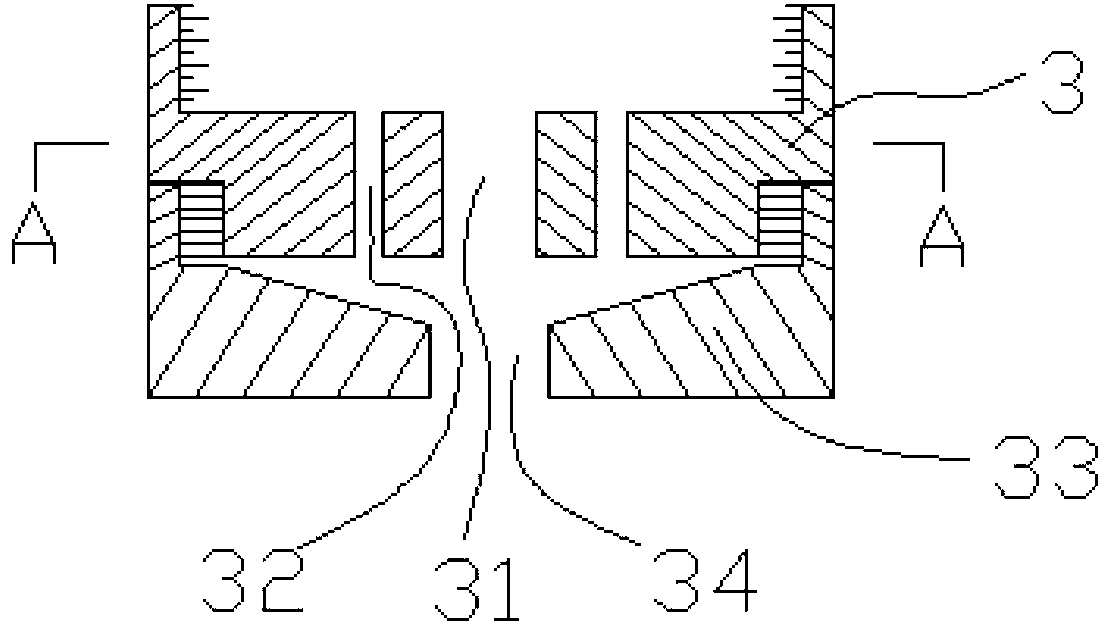

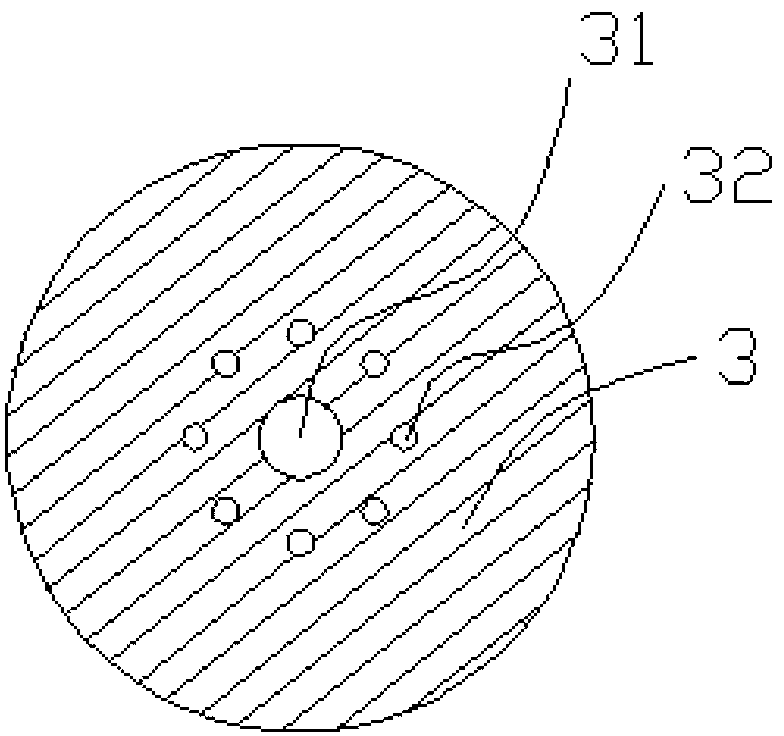

[0032] Such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com