Liquid circulation processing device and method for bast fibers

A technology of bast fiber and liquid circulation, which is applied in the direction of processing textile material carriers, processing textile material equipment configuration, textile material contact export textile material processing, etc., and can solve problems such as incomplete processing, uneven processing, and affecting production efficiency. , to achieve the effects of reducing the consumption of chemical additives, uniform and thorough processing results, and fast processing cycle speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Definition of terms: The liquid circulation processing of "bast fiber" mentioned in the present invention all includes the liquid circulation processing of yarn.

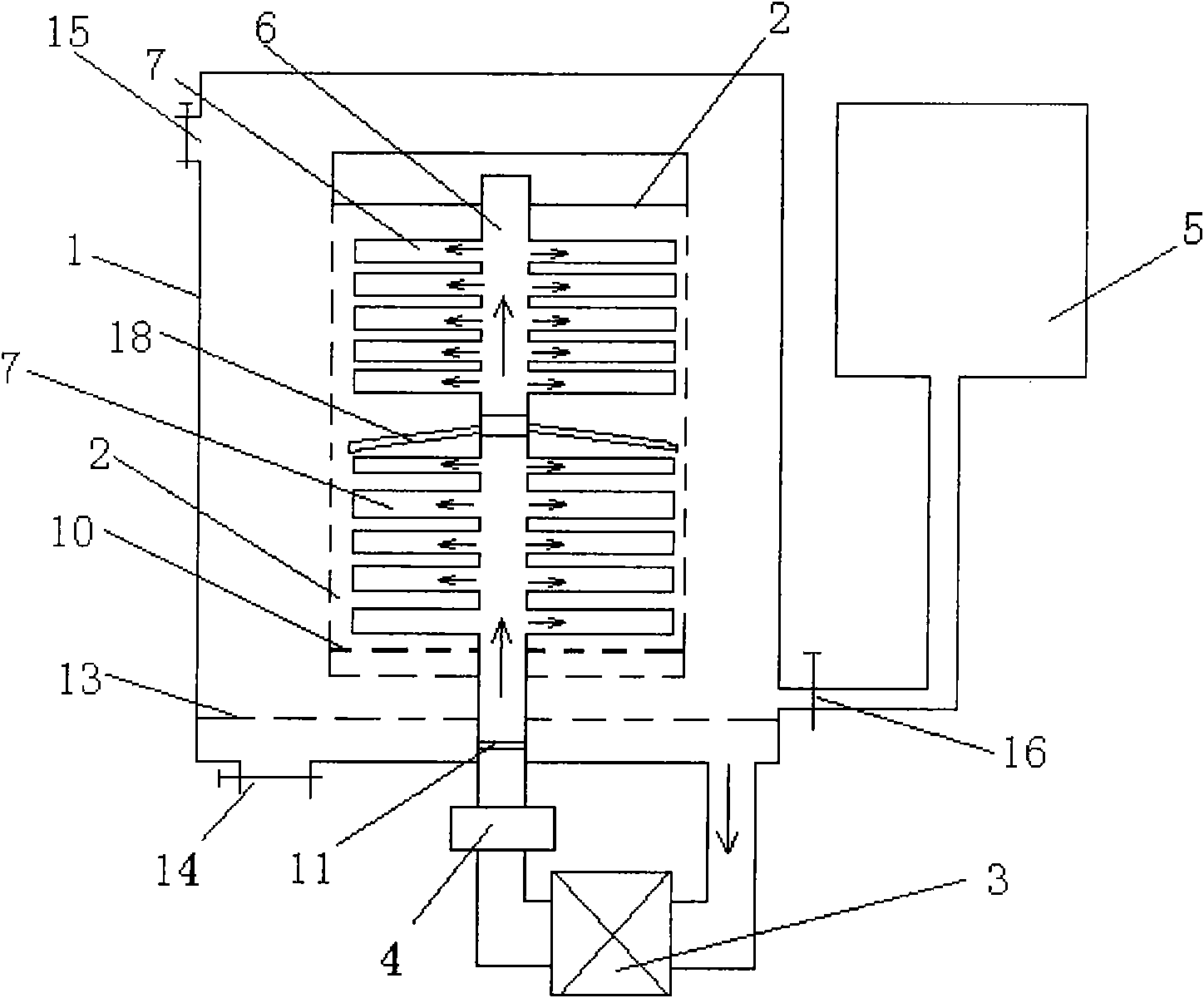

[0020] Such as figure 1 As shown, the present invention includes a barrel-shaped master cylinder 1 with a lid. A yarn hanging device 2 is provided in the master cylinder 1, and there is a certain gap between the main cylinder 1 and the circumferential edge of the yarn hanging device 2. A main pump 3 is arranged outside the main tank 1. The water outlet of the main pump 3 is connected to a heat exchange device 4, and the water outlet of the heat exchange device 4 is connected to the water inlet of the yarn hanging device 2 in the main tank 1. The water outlet is connected to the water inlet of the main pump 3. A secondary cylinder 5 is also provided outside the main cylinder 1, and the secondary cylinder 5 functions to supplement the main cylinder 1 with chemical additives.

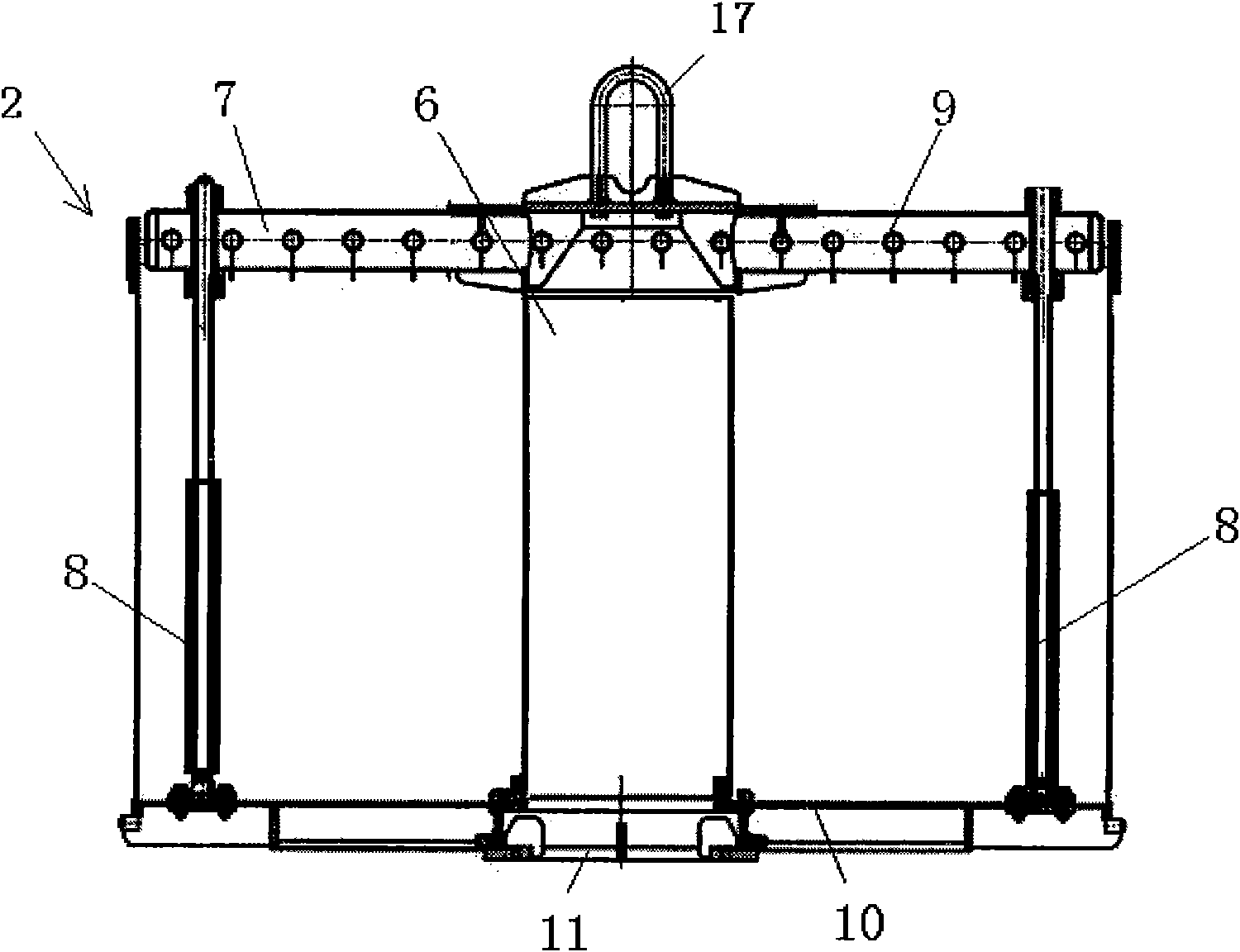

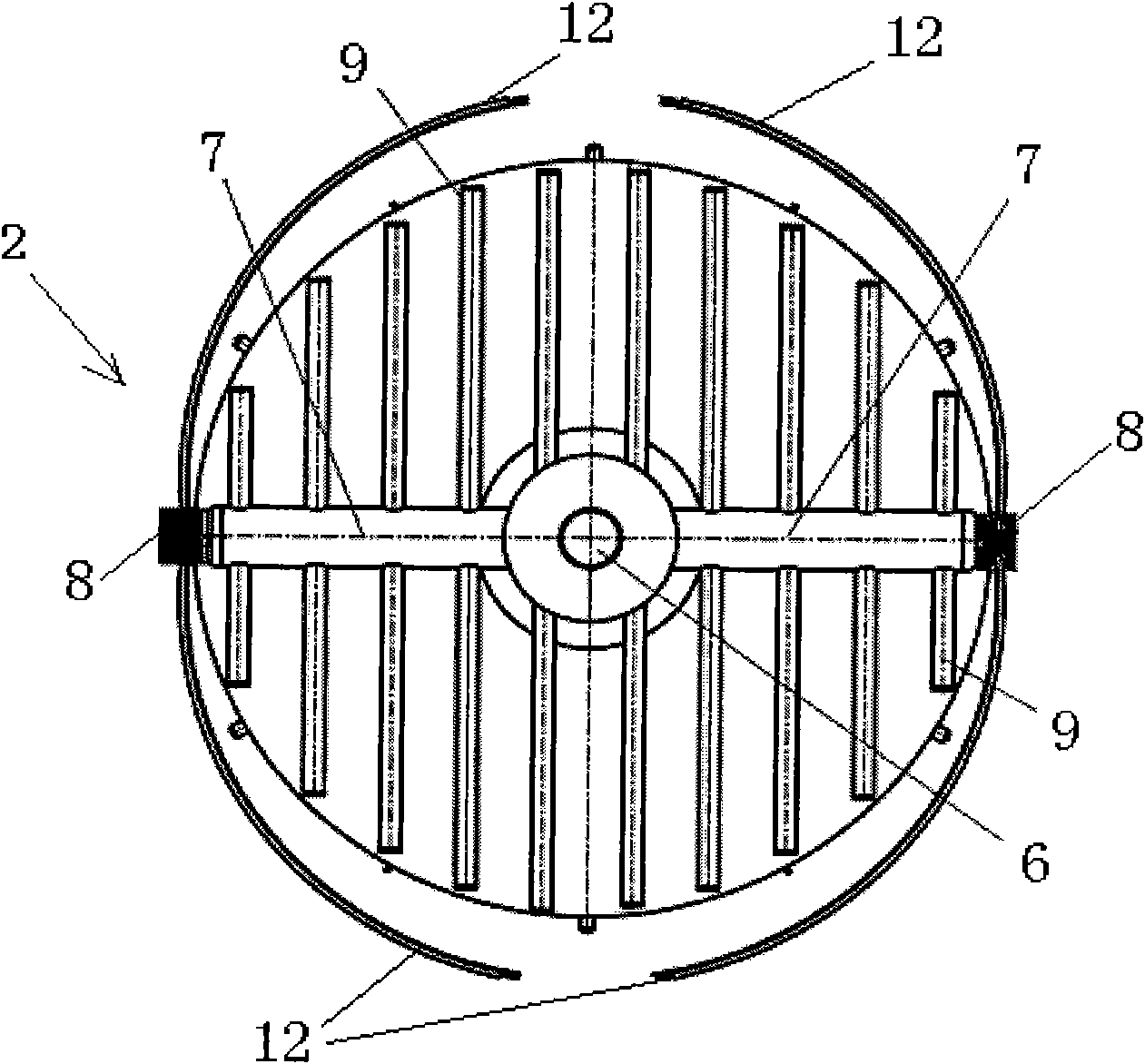

[0021] Such as figure 2 The yarn hang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com