Spray painting machine

A spraying machine and rack technology, applied in the direction of spraying devices, etc., can solve the problems of difficulty in achieving uniform coverage of sprayed coatings on workpieces, complicated control of power devices, and increased spraying time, so as to meet the needs of mass production and improve product cleanliness , Improve the effect of product surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in all embodiments are only for convenience of description, and are not intended to limit the implementation of the present invention Changes or adjustments in their relative relationships, without substantial changes in technical content, should also be regarded as the scope of implementation of the present invention.

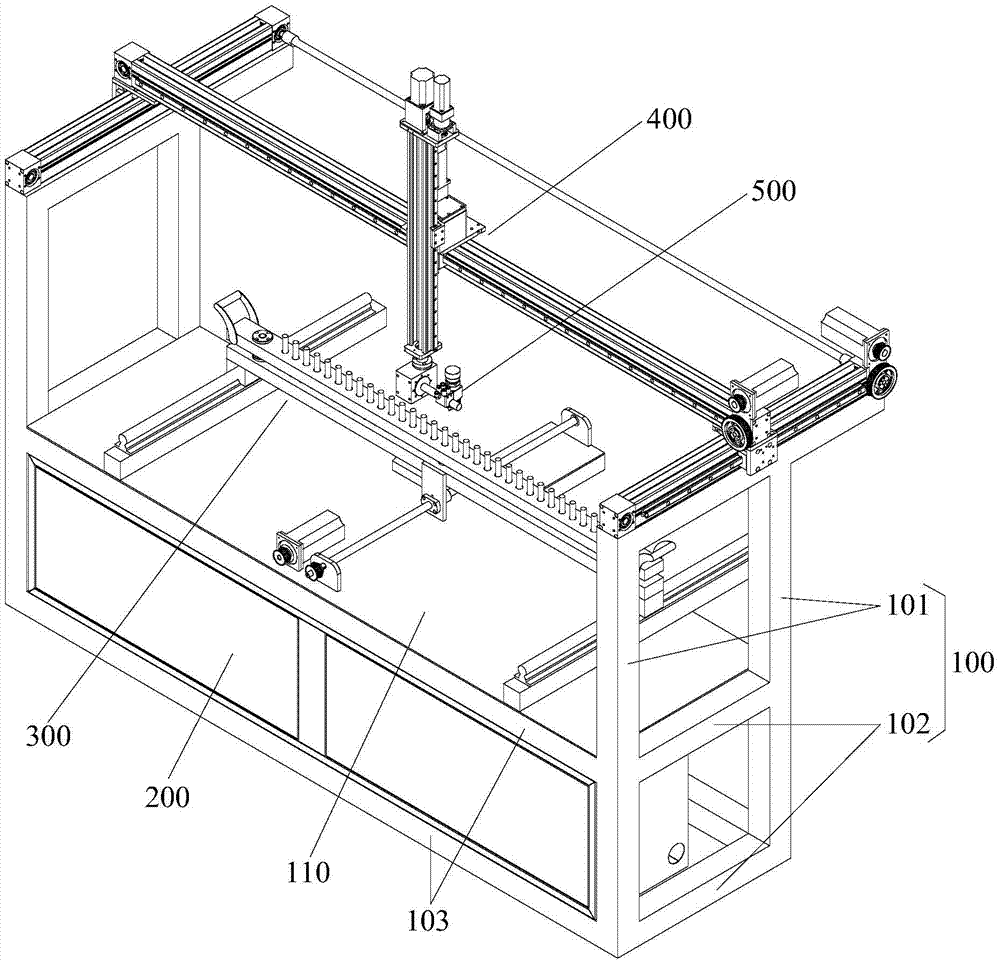

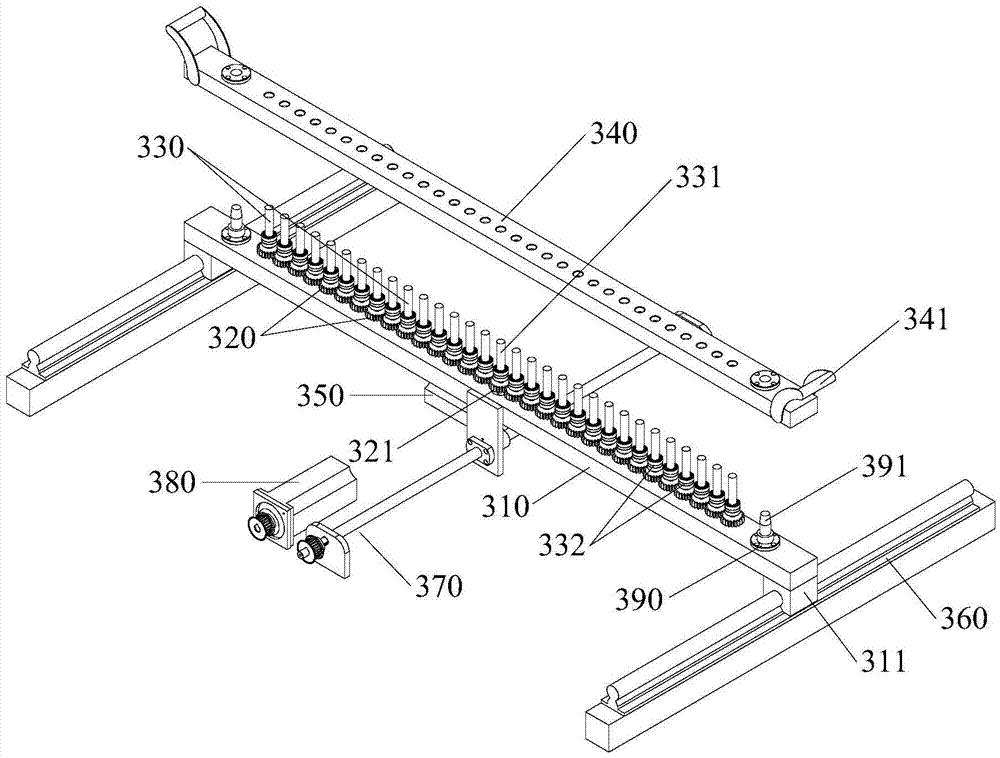

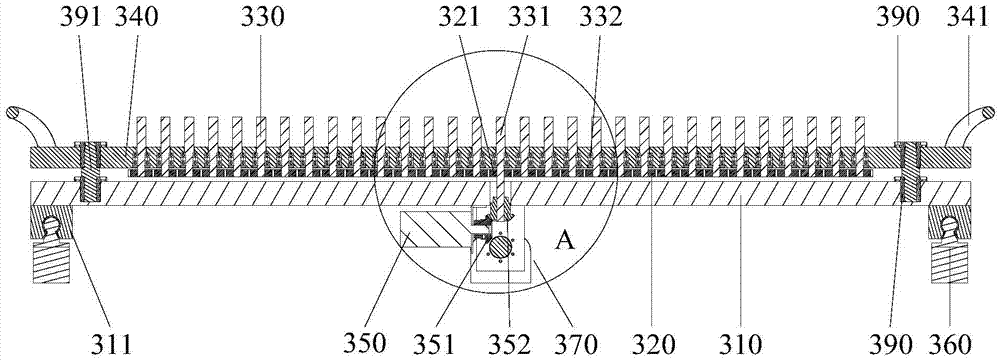

[0028] See figure 1 , a spraying machine designed in a preferred embodiment of the present invention, which includes: frame 100, horizontal electric box 200, synchronous turntable 300 and five-axis mechanism 400, horizontal electric box 200, synchronous turntable 300 and five-axis mechanism 400 They are arranged on the rack 100 sequentially from bottom to top.

[0029] Specifically, the frame 100 includes two left and right unilateral frames opposite to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com