Production process of integral kelly stem

A production process and kelly technology, applied in the fields of forging, machining, steelmaking, and heat treatment, can solve the problems of short service life, narrow application range, complex structure, etc., and achieve long service life, good product quality, and production process economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

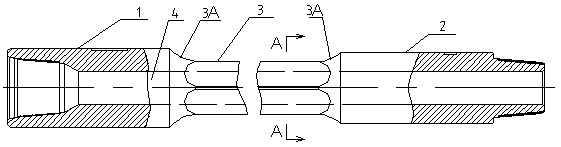

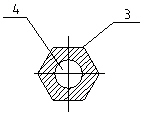

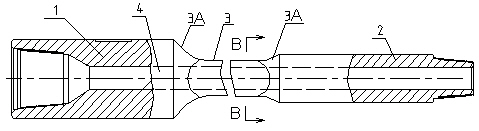

[0018] Below in conjunction with specific embodiment and appended figure 1 -4 further introduces the technical solution of the present invention in detail, but the protection of the present invention is not limited thereto.

[0019] Embodiments 1 to 5 are the production process of 133.4mm wide kelly (square kelly or hexagonal kelly), and embodiments 6 to 10 are 88.9mm wide kelly (square kelly or hexagonal kelly). Hexagonal drill pipe) production process. see Figure 1 to Figure 4 , the present invention comprises following five processes by operation:

[0020] (1) Smelting process:

[0021] Steel 4145H for oil drilling tools is smelted in an electric furnace and vacuum refined, then vacuum degassed and cast into steel ingots. After demolding, the steel ingots are hot sent to the forging process. Among them, the baking temperature of the refining bag is ≥900°C, the reducing atmosphere is maintained during the refining period, and the flow of argon gas is well controlled, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com