Large-size platform type digital colored printer

A color printer and platform-based technology, applied in typewriters, printing, etc., can solve the problems of low technical parameters, unstable operation of equipment, low precision, etc., and achieve the effect of firm ink marks, clear lines and accurate printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

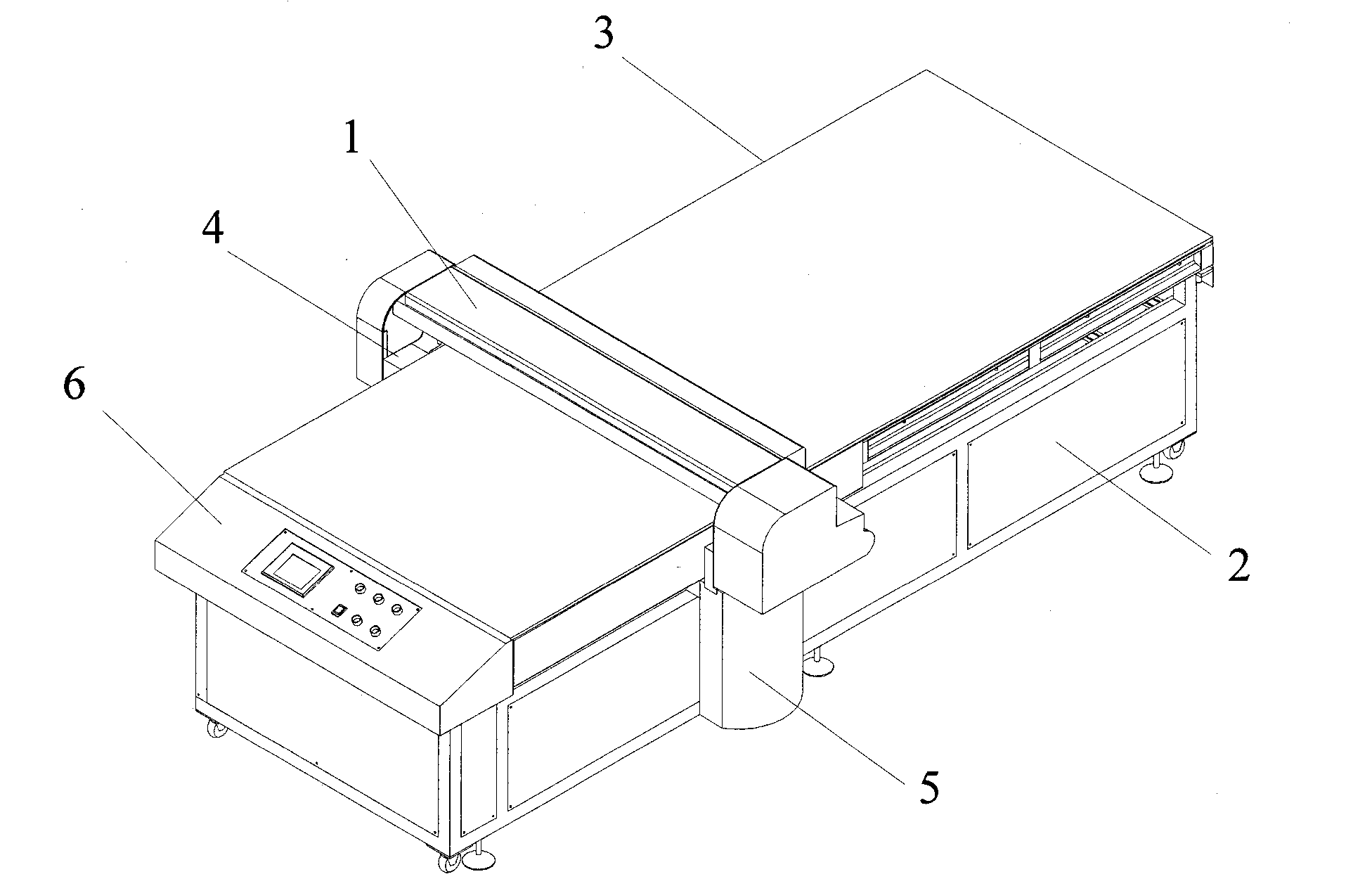

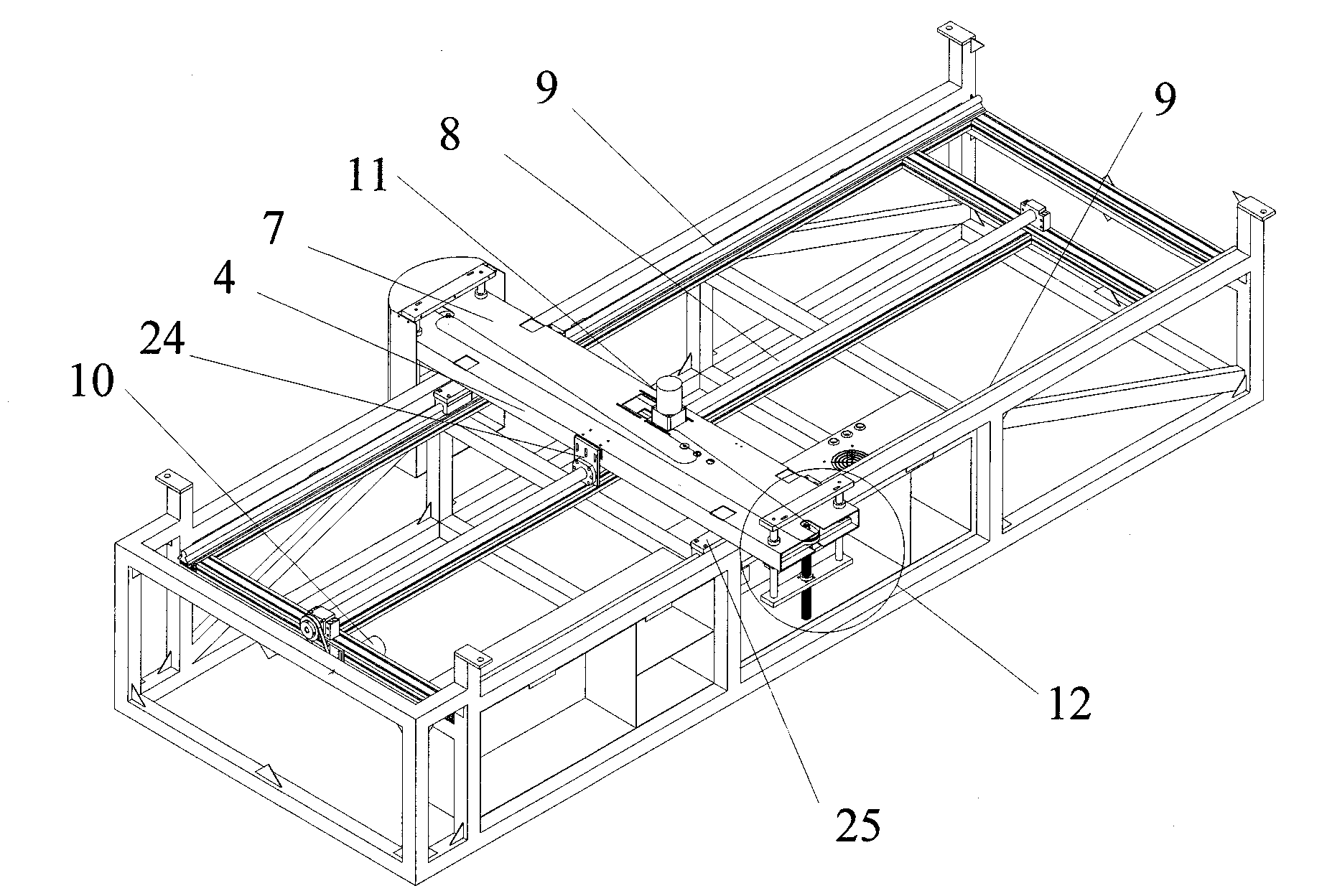

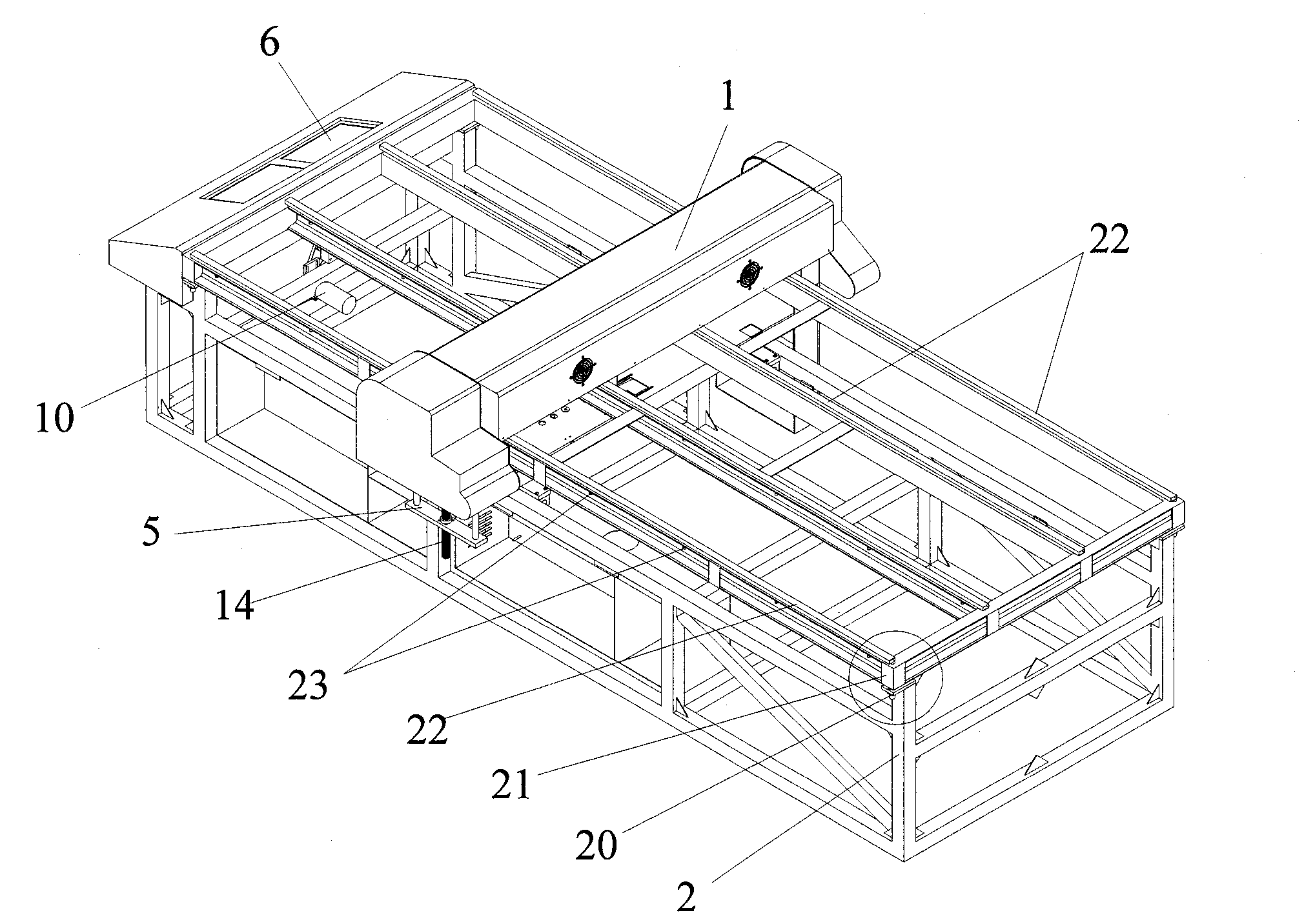

[0018] The present invention's large platform digital color printer, such as figure 1 , figure 2 and image 3 As shown, it includes a printing inkjet head 1, a frame base 2, a printing platform 3, a moving mechanism 4, a lifting mechanism 5, a console 6 and a machine tool computer numerical control circuit, and the printing inkjet head 1 is installed on the frame base 2 On the moving mechanism 4 arranged on both sides, the moving mechanism 4 is connected with the ball screw 8 and the linear guide rail 9 installed on the frame base 2 through the ball screw nut and the slider set across the frame base 2 walking beam 7 Cooperate, and be driven by the drive motor 10 to move back and forth; the lifting mechanism 5 is composed of a lifting motor 11 arranged on the walking beam 7 and a lifting frame 12 installed at both ends, and the lifting moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com