Multi-nozzle adjusting method for overprinting

An adjustment method and multi-nozzle technology, applied in printing, printing devices and other directions, can solve the problems of time-consuming, relying on experience, unfavorable standardized production, etc., and achieve the effect of reducing labor, high degree of automation, and reducing the time for machine adjustment and preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below.

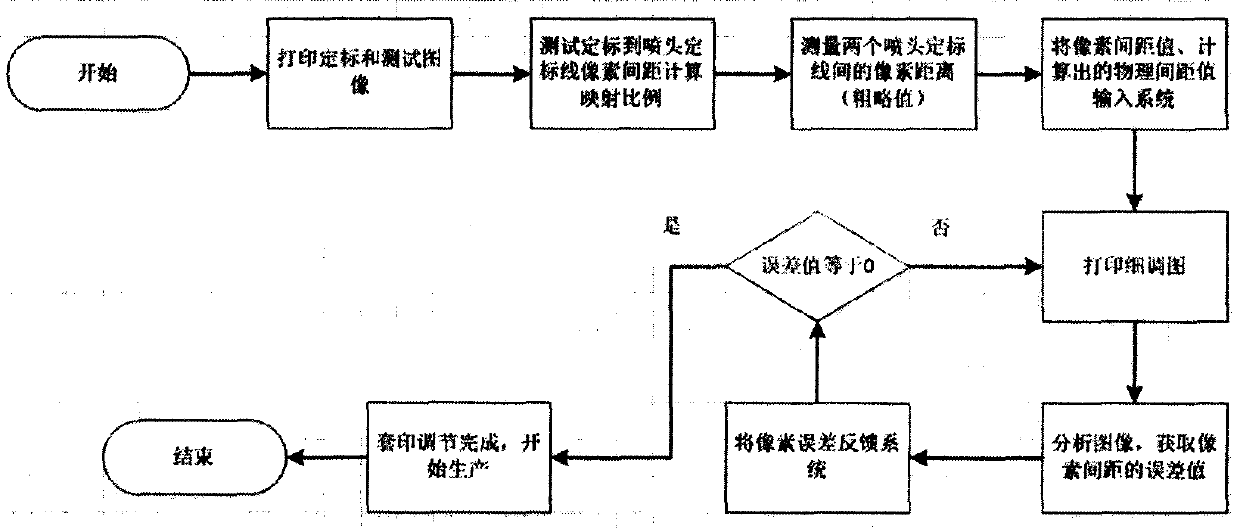

[0034] Such as figure 1 As shown, a multi-nozzle adjustment method for overprinting includes the following steps:

[0035] (1) Coarse adjustment stage

[0036] Print the calibration and test chart, calculate the actual distance between adjacent nozzles through the calibration and test chart, and input it into the inkjet printing system for preliminary parameter correction. Step (1) includes the following steps:

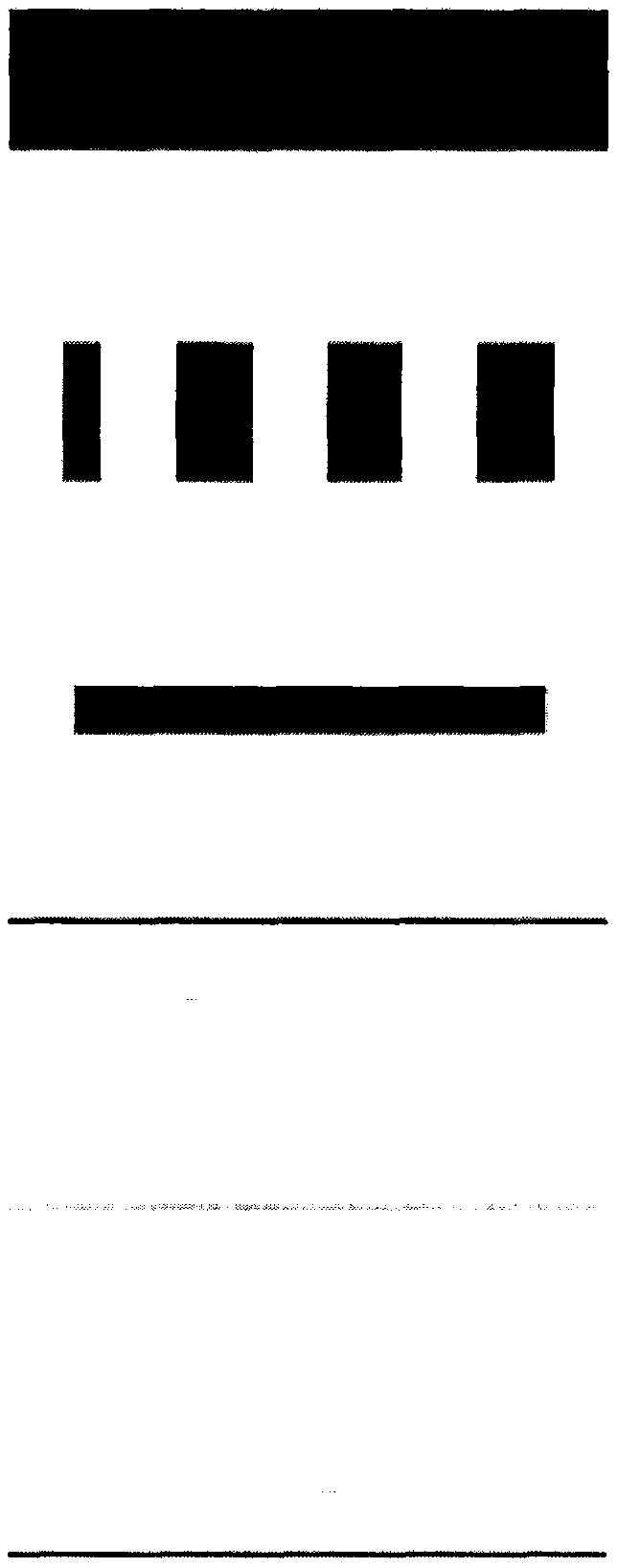

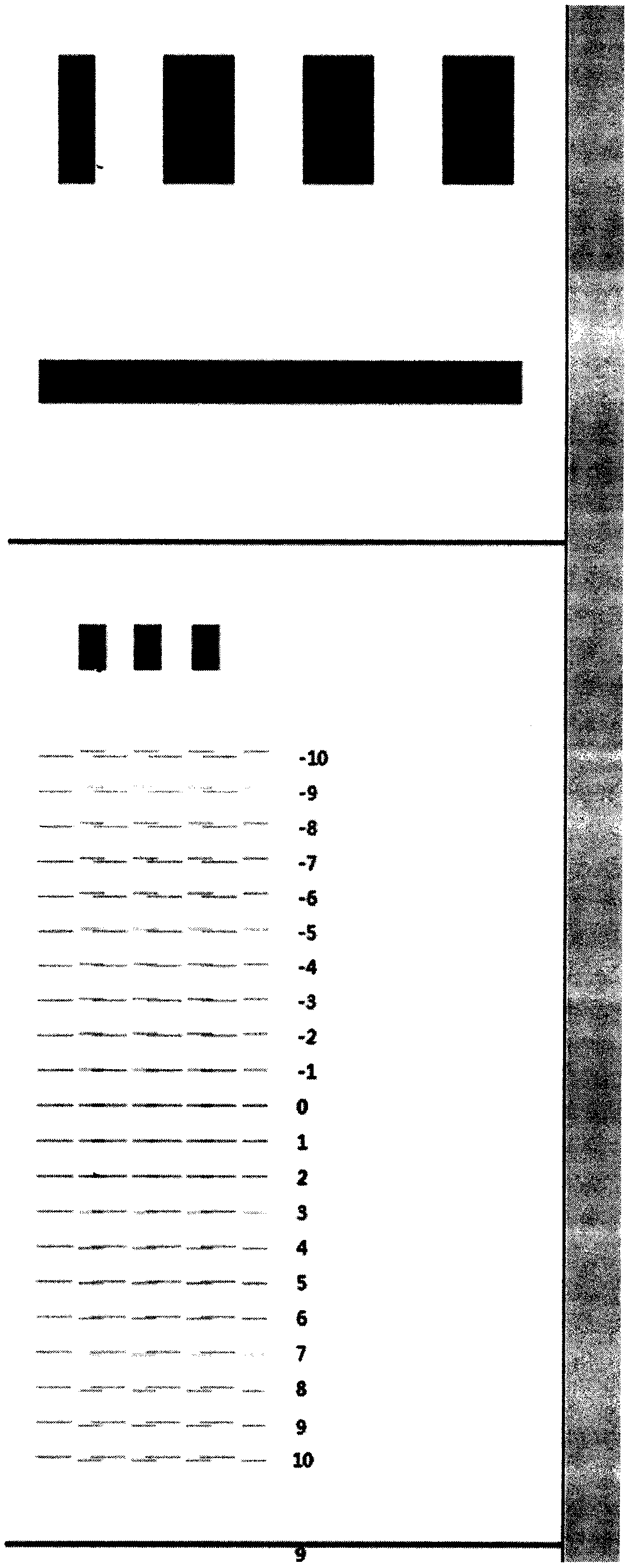

[0037] (11), jet printing calibration and test chart (such as figure 2 shown);

[0038] (12), the image of the calibration and the test chart of the collection step (11) jet printing;

[0039] (13), analyze the collected image of step (12):

[0040] (131) Determine the correspondence relationship Fy between the physical distance / pixel

[0041] The physical distance between the two adjacent calibration lines of the calibration and test chart is constant, set as Yd, and meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com