Bulk material feeding machine

A technology of feeding machine and bulk material, applied in the field of feeding mechanism, can solve the problems of strong pertinence, large space occupation, single function, etc., and achieve the effect of improving production efficiency, reducing production cost and shortening machine adjustment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

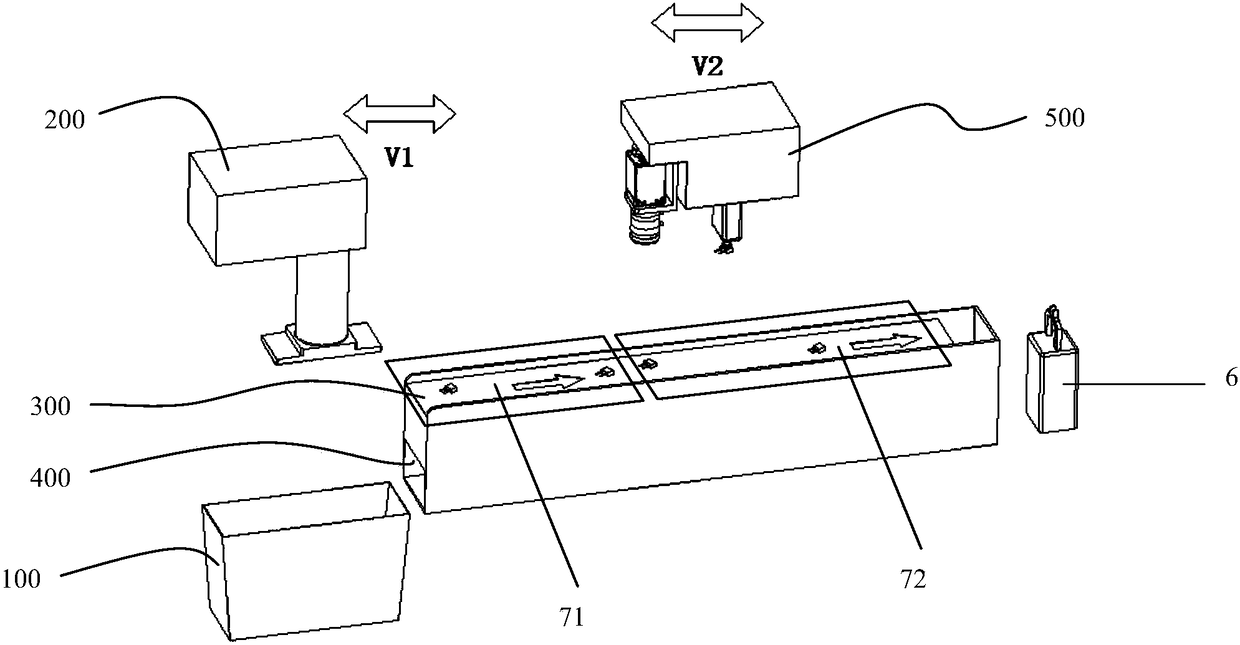

[0034] figure 1 It is a schematic diagram of the principle of a bulk feeding machine provided by the present invention.

[0035] Such as figure 1 A bulk material loading machine shown includes a material storage module 100, a material loading module 200, a conveying module 300, a return module 400, an identification and distribution system 500, wherein the material loading module 200 is located in the storage Above the material module 100, the identification and distribution system 500, the delivery module 300 and the return module 400 are arranged from top to bottom, and the delivery directions of the delivery module 300 and the return module 400 are opposite; the feeding module 200 Acquire the workpieces from the storage module 100, and place the workpieces in a single layer on the conveying module 300. The identification and distribution system 500 identifies the workpieces on the conveying module 300 and obtains the workpieces that are identified as the correct state. Th...

Embodiment 2

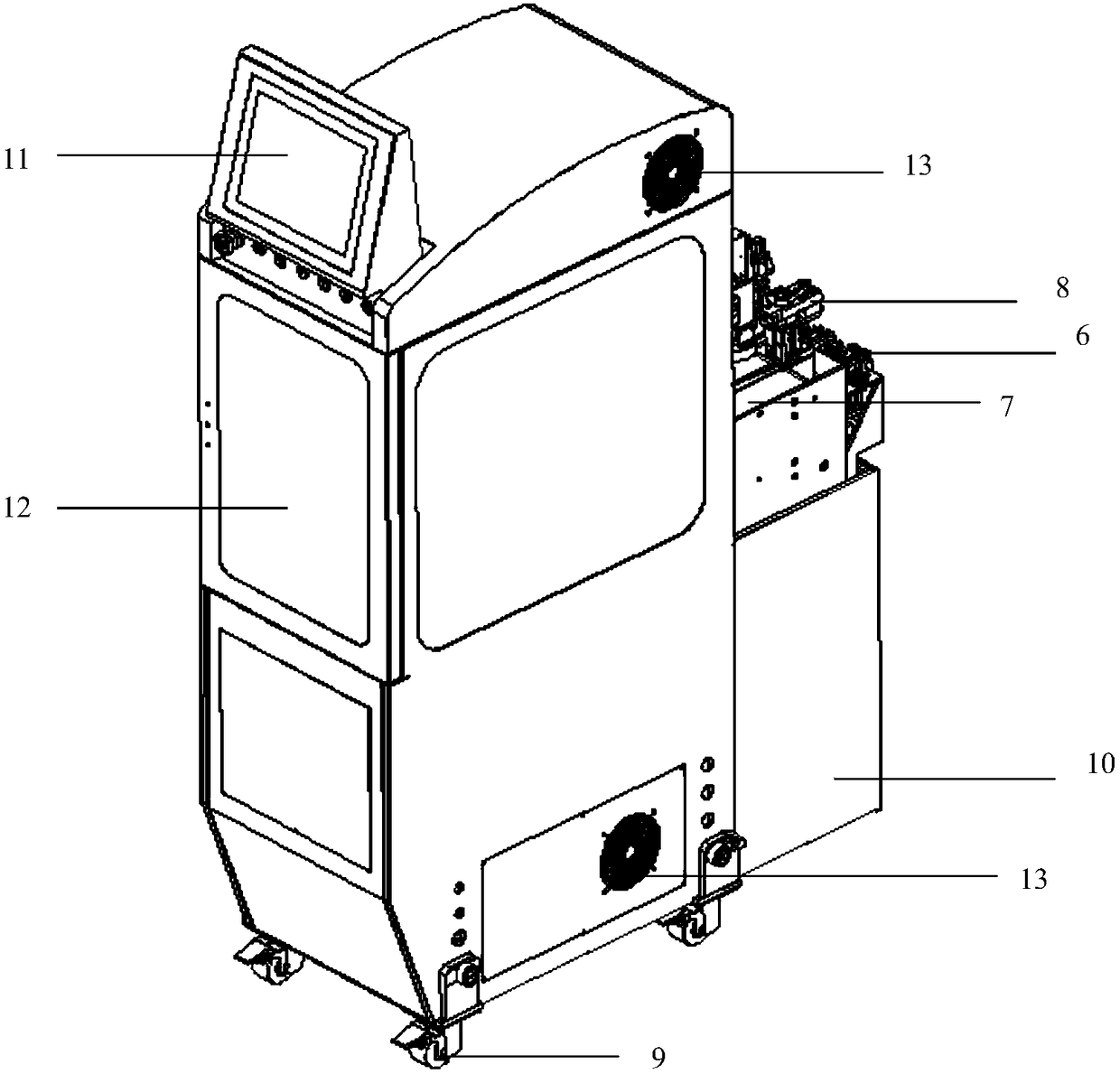

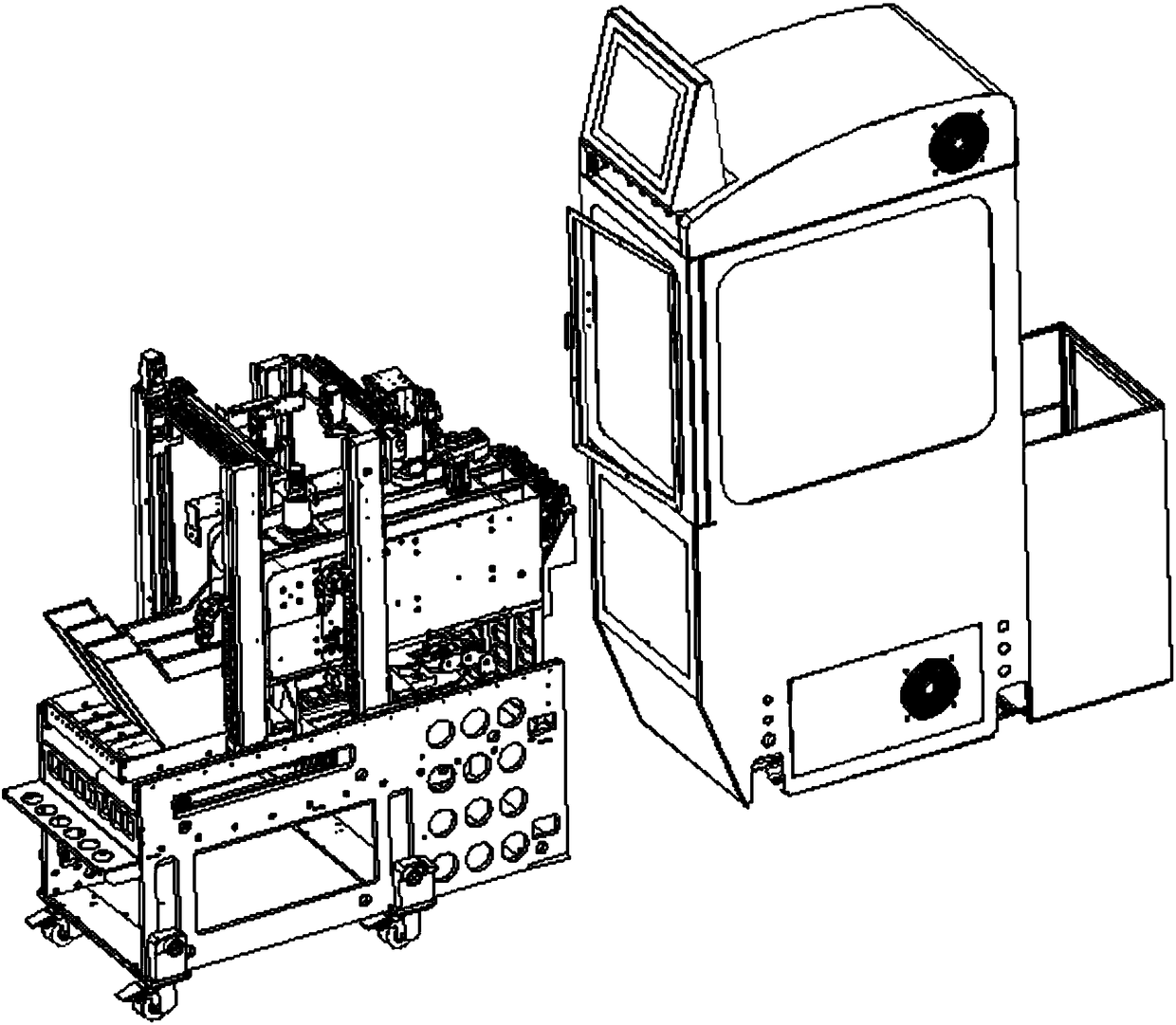

[0049] Figure 2-Figure 6 The specific structure of a bulk feeding machine and its parts is shown.

[0050] Such as Figure 2-6 A bulk feeding machine shown includes a base 1, a silo 2 arranged above the base 1, a feeding manipulator 3, a distributing manipulator 4, a CCD assembly 5, an adapter assembly 6 and a conveying line 7, the The conveying line 7 is laid horizontally along the front-to-back direction, and the conveying line 7 is provided with a throwing position 71 and a CCD identification area 72 from front to back, wherein,

[0051] The feed bin 2 is arranged at the front end of the conveying line 7, the feeding manipulator 3 is arranged at the front end of the conveying line 7 and above the feed bin 2, and the distributing manipulator 4 is arranged at the front end of the conveying line 7. Above the conveying line 7, the adapter assembly 6 is arranged at the rear end of the conveying line 7.

[0052] The operation process of the bulk material feeding machine is: t...

Embodiment 3

[0059] On the basis of Embodiment 2, the multi-degree-of-freedom acquisition component 8 is further improved.

[0060] Such as Figure 6 As shown, the multi-degree-of-freedom acquisition component 8 includes a rotation mechanism in the ZY plane, a rotation mechanism in the XY plane, a vertical mechanism in the Z direction, and an acquisition head connected in sequence.

[0061] Further, the rotation mechanism in the ZY plane includes a rotation cylinder / motor 81 in the ZY plane, and the rotation mechanism in the XY plane includes a rotation cylinder / motor 82 in the XY plane (the maximum rotation angle in the ZY plane is 90°), so The Z-direction up and down mechanism includes a Z-direction lifting cylinder / motor 83 (the maximum rotation angle in the XY plane is ±180°), and the acquisition head includes grippers or is connected with a second vacuum control system (not shown in the figure) The second vacuum suction head 84.

[0062] Grabbing or sucking can be used to design acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com