Single-layer plastic pipe extrusion fine adjustment die

A technology for plastic pipes and molds, applied in the field of single-layer plastic pipe extrusion fine-tuning molds, can solve the problems of waste of raw materials, high cost, high processing technology requirements, etc., and achieve the effect of reducing machine adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

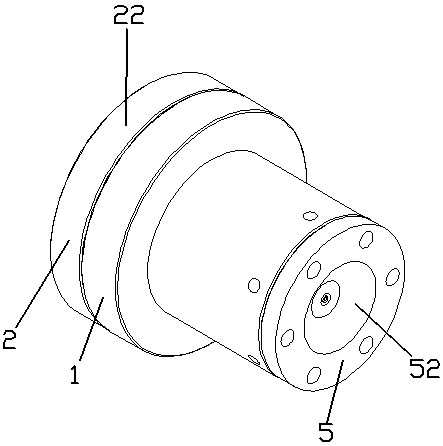

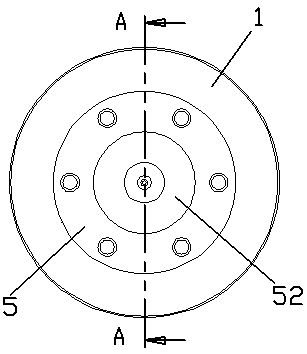

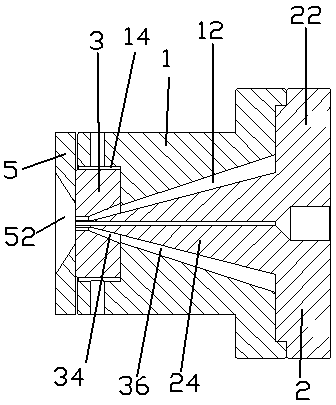

[0025] see Figure 1 to Figure 3 , a single-layer plastic pipe extrusion fine-tuning die, which includes an outer mold 1, a core mold 2, a deviation adjustment module 3, six adjustment screws (not shown in the figure), and a locking plate 5.

[0026] The outer mold 1 is a revolving body, and a trumpet-shaped accommodation groove 12 is opened in the center thereof, and the diameter of the accommodation groove 12 gradually increases from the front end to the rear end.

[0027] The front end of the outer mold 1 is provided with a cylindrical mounting groove 14 . The installation groove 14 communicates with the receiving groove 12 .

[0028] Six threaded holes (not shown) are opened on the front wall of the installation groove 14 . The six screw holes (not shown) surround the center of the mounting groove 14 at intervals of equal angles and distances.

[0029] The rear end of the mandrel 2 is provided with a mounting plate 22, and the mounting plate 22 is installed and fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com