Film packaged external pin pressing device

A technology of thin-film packaging and external pins, which is applied to optics, instruments, electrical components, etc., can solve problems such as time-consuming, low production line efficiency, and increased personnel training costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

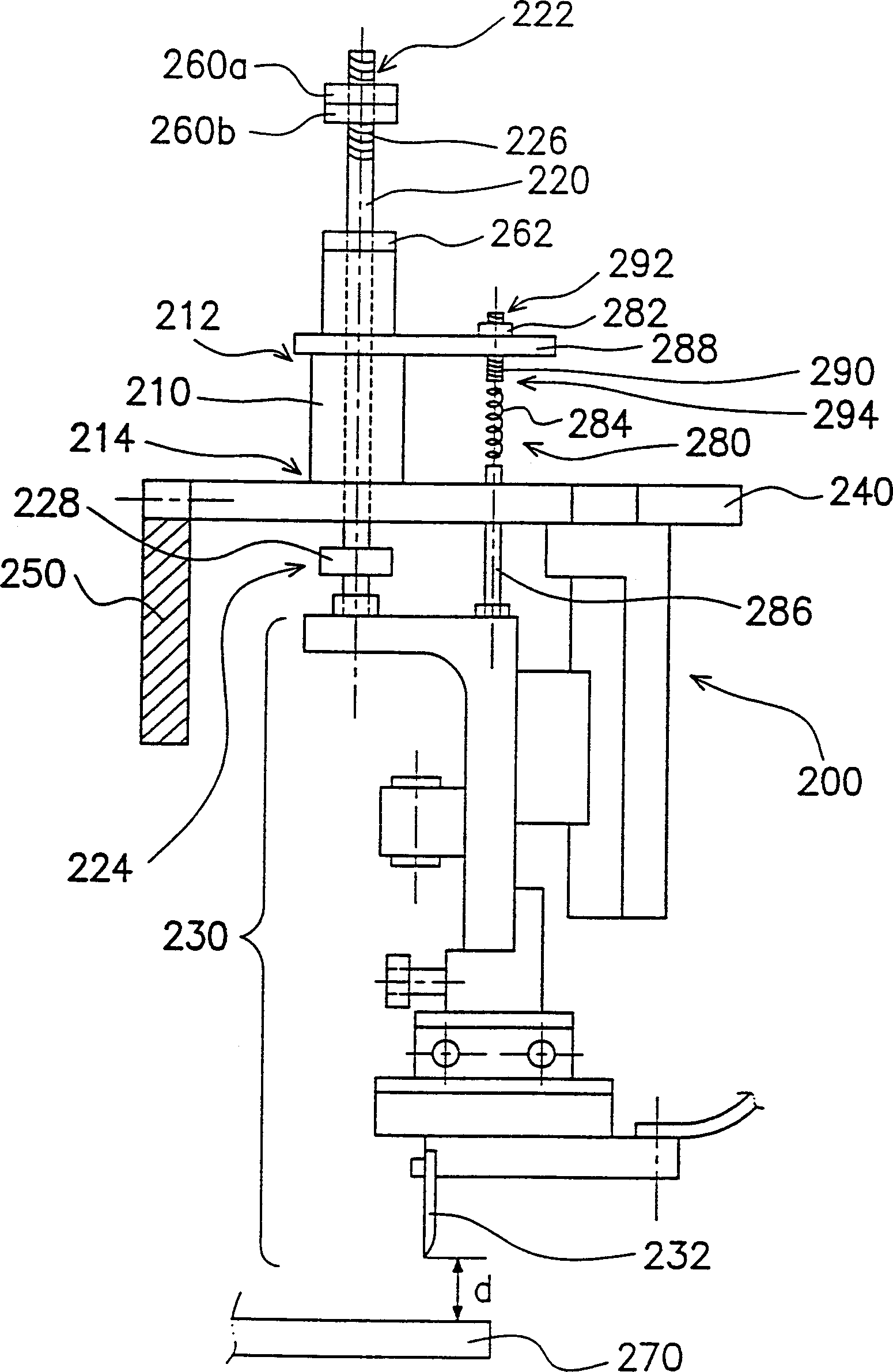

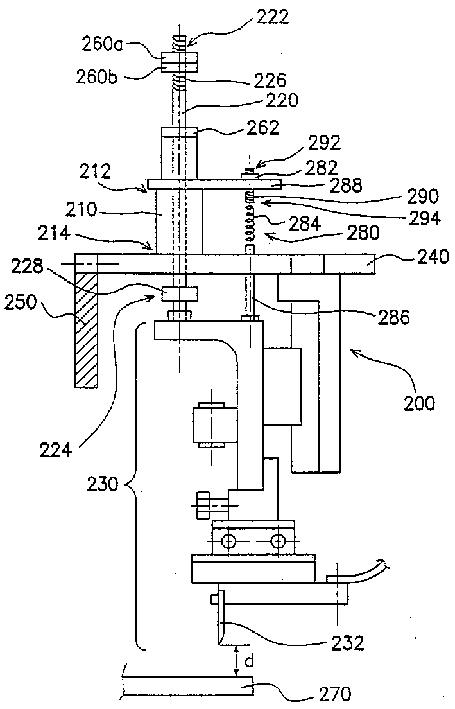

[0034] Please refer to figure 2 , the crimping device 200 includes a cylinder 210, a connecting rod 220, a crimping head assembly 230, a platform 240, and a support plate 250, wherein the platform 240 is fixed on the support plate 250, and the cylinder 210 is fixed on the platform 240 superior. The cylinder 210 has a first end 212 and a second end 214, and the connecting rod 220 runs through the inside of the cylinder 210, and the connecting rod 220 has a first end 222 and a second end 224, and the first end 222 of the connecting rod 220 extends out of the cylinder 210 The outside of the first end 212 of the connecting rod 220 is connected with an adjustment assembly, and the first end 222 of the connecting rod 220 has a threaded structure 226, and the adjustment assembly is composed of two adjustment nuts 260a, 260b, the adjustment nut 260a , 260b are bolted on the threaded structure 226 . The second end 224 of the connecting rod 220 extends out of the second end 214 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com