Large concrete structural body pre-supporting-free demolition method

A concrete and structural technology, applied in building construction, building maintenance, construction, etc., can solve the problems of time and manpower consumption, limited activity space for construction personnel, inconvenient operation and dismantling, etc., and achieve easy implementation and high activity space increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings.

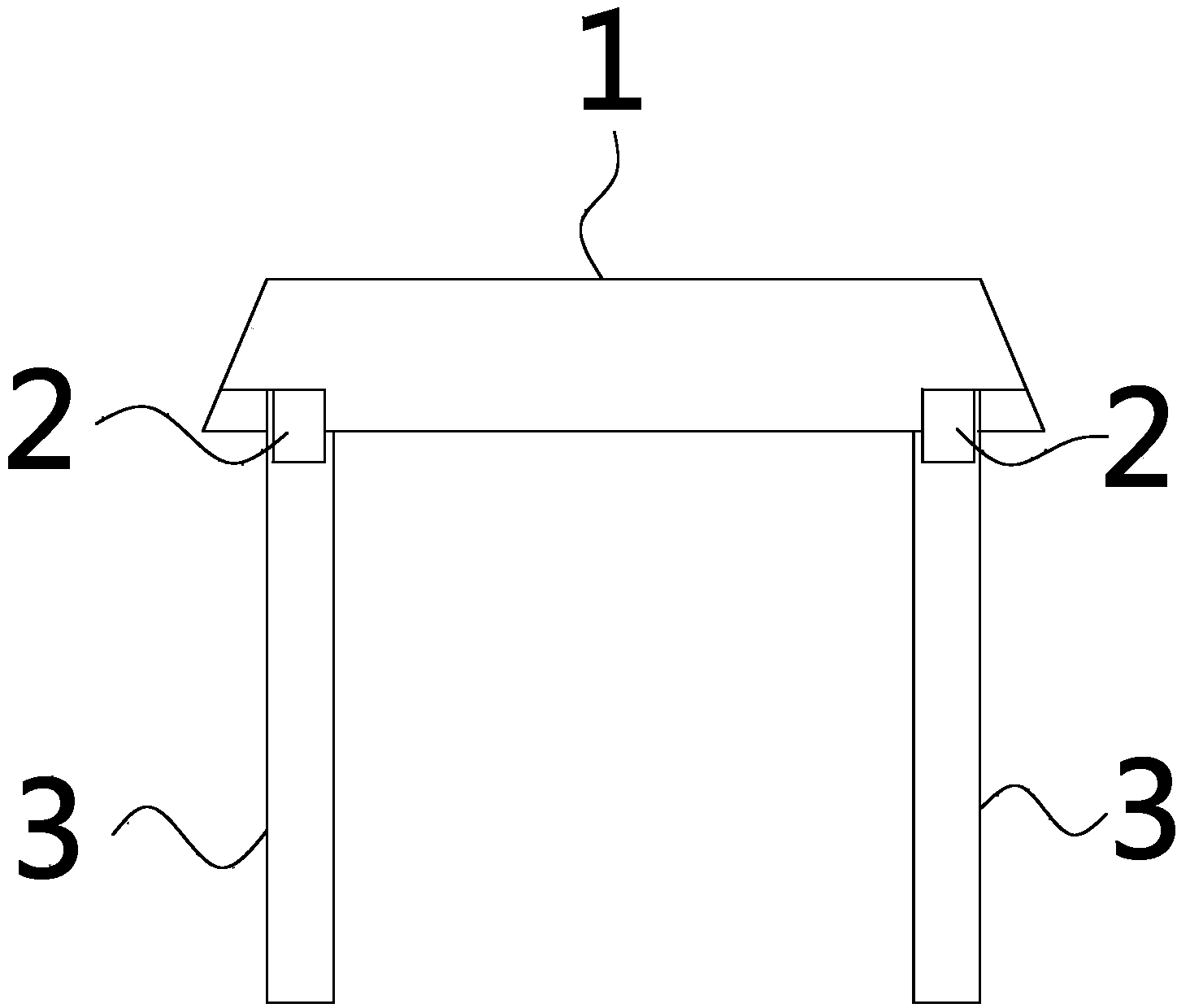

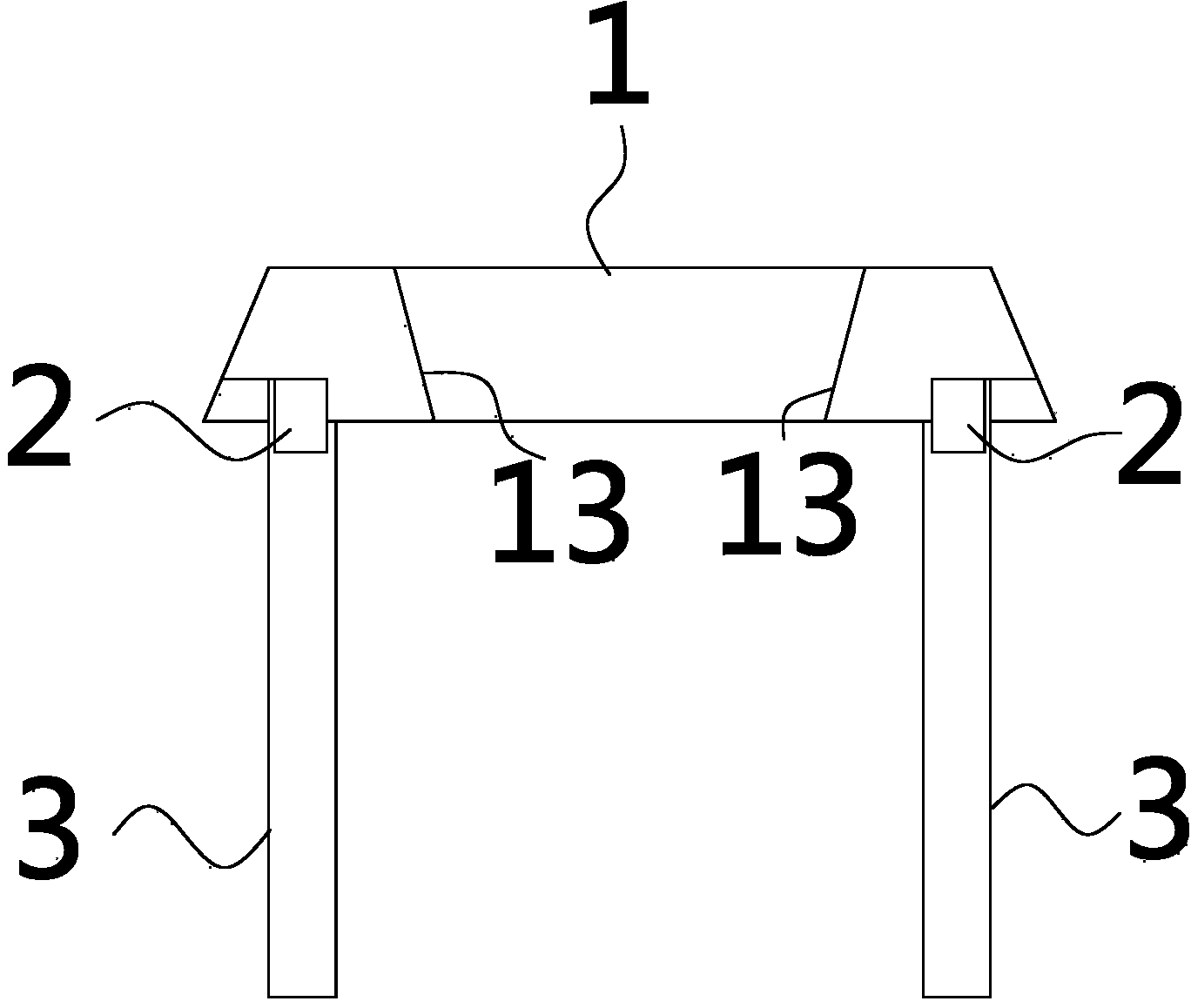

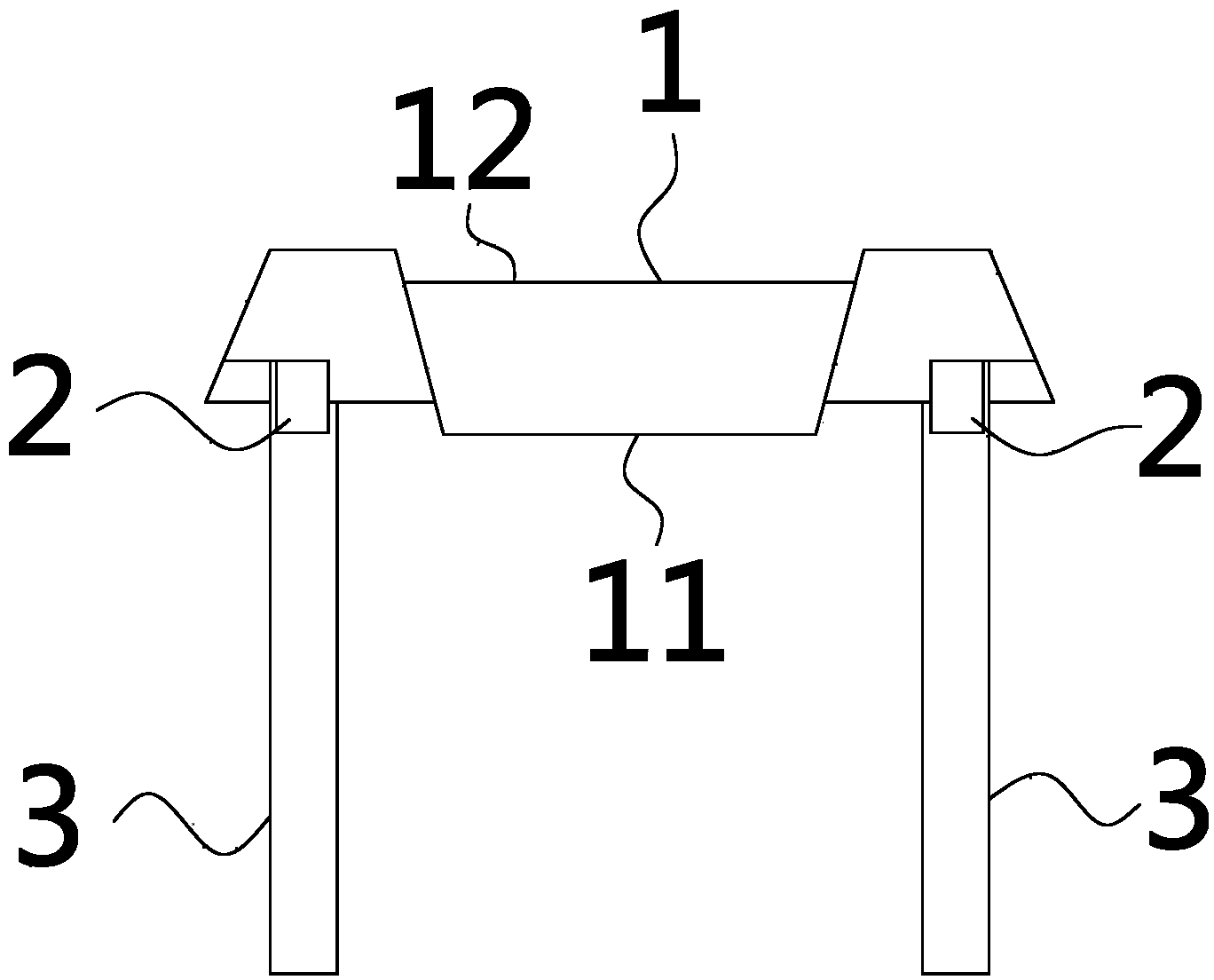

[0022] Such as Figure 1 to Figure 6 The shown method for dismantling a large concrete structure without pre-support, the large concrete structure comprising a cover plate 1, a beam used to support the cover plate 1, a supporting column 3 used to support the beam 2, includes the following steps:

[0023] a. Select the cover plate 1 that needs to be removed, and cut the selected cover plate 1 obliquely along the thickness direction of the cover plate 1. The oblique cutting surface 13 of the cover plate formed by the oblique cutting cuts the top surface of the cover plate 1 Separate the top surface 12 of the cover plate, the oblique cutting surface 13 of the cover plate separates the bottom surface of the cover plate 1 from the bottom bottom surface 11 of the cover plate, and the area of the top surface 12 of the cover plate is larger than the area of the bottom bottom surface 11 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com