Building template production line and building template production method using same

A construction formwork and production line technology, applied in applications, household components, household appliances, etc., can solve the problems of low production efficiency, low product reuse times, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

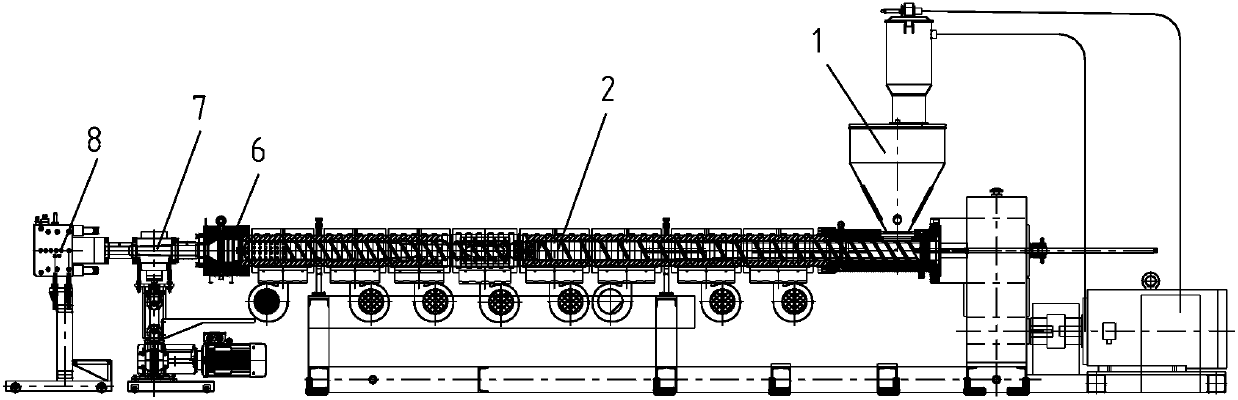

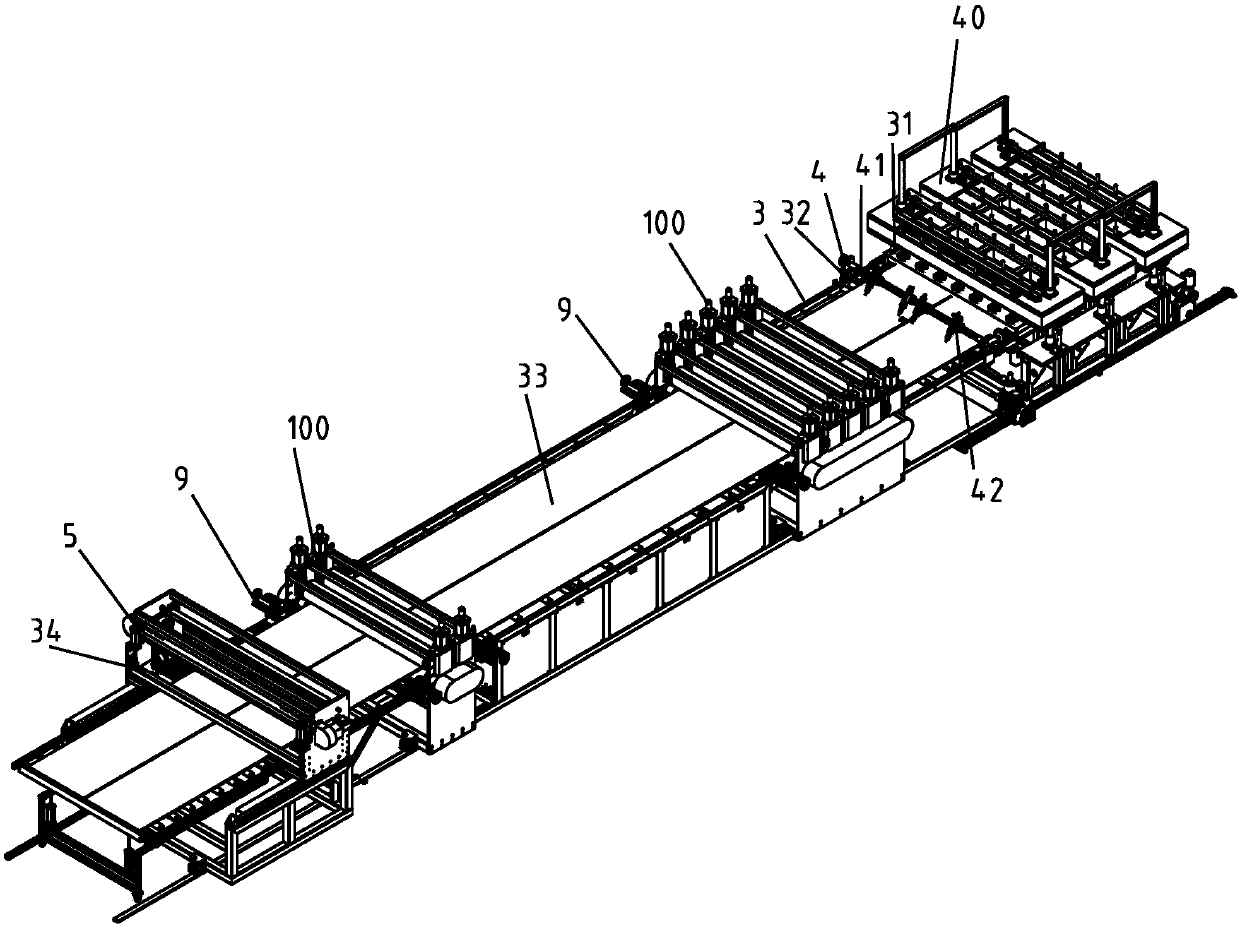

[0032] Such as Figure 1~4 As shown, a building formwork production line, it includes:

[0033] The extruded material part, the extruded material part includes a feeder 1 and an extruder 2, the feeder 1 is used to feed the building formwork formula material to the entrance of the extruder 2, and the extruder Machine 2 is used to extrude the building formwork formulation material to form extruded material;

[0034] The cooling conveying table 3 used to transport the product forward, the cooling conveying table 3 has a shaping table installation part 31, a fixed-width slitting part installation part 32, a cooling conveying part 33 and a fixed-length cross-cutting part from back to front. Component mounting part 34;

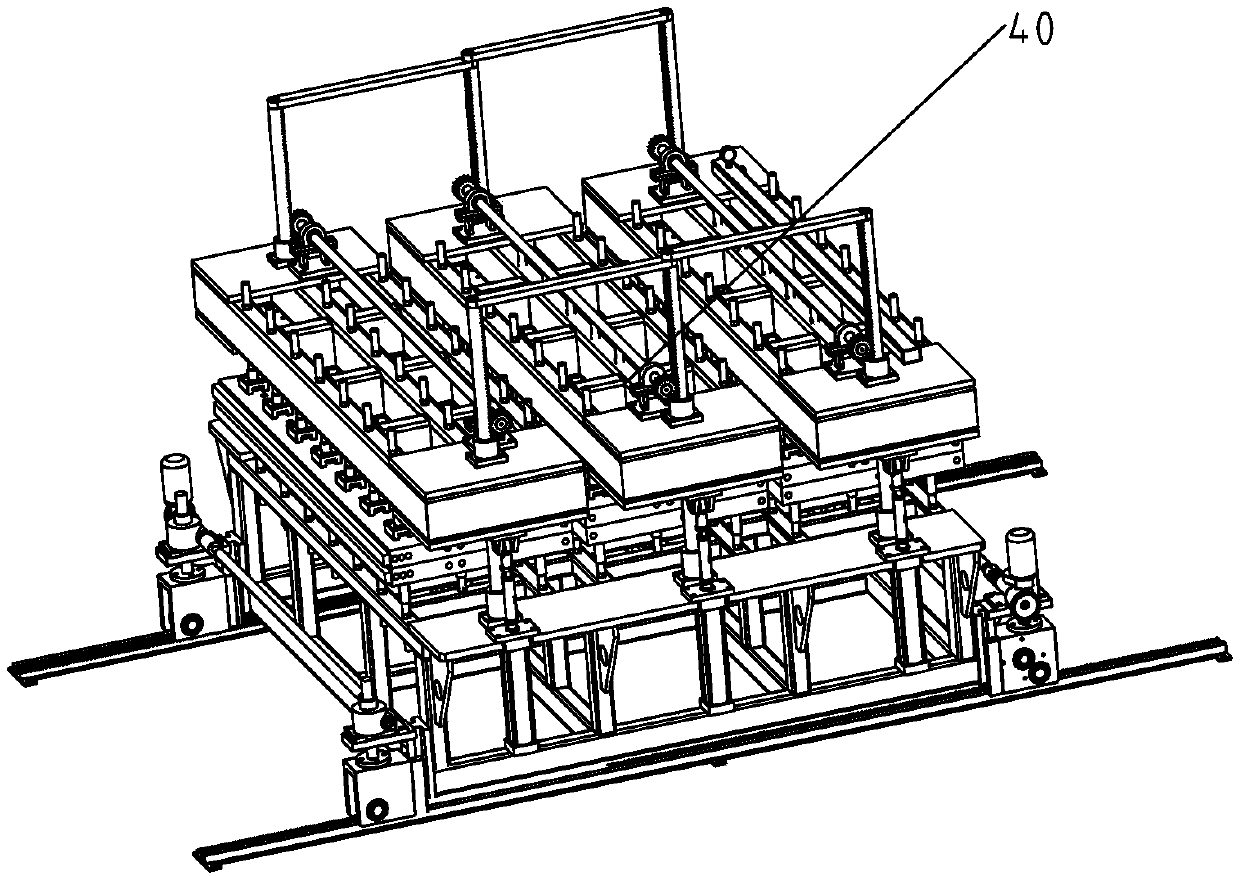

[0035] A shaping table 40 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com