Numerical control lathe power shaft center correcting device

A technology of CNC lathes and correction devices, applied in auxiliary devices, turning equipment, accessories of tool holders, etc., can solve the problems of inability to accurately correct the center of the power shaft, and achieve the effect of saving adjustment time and requiring guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

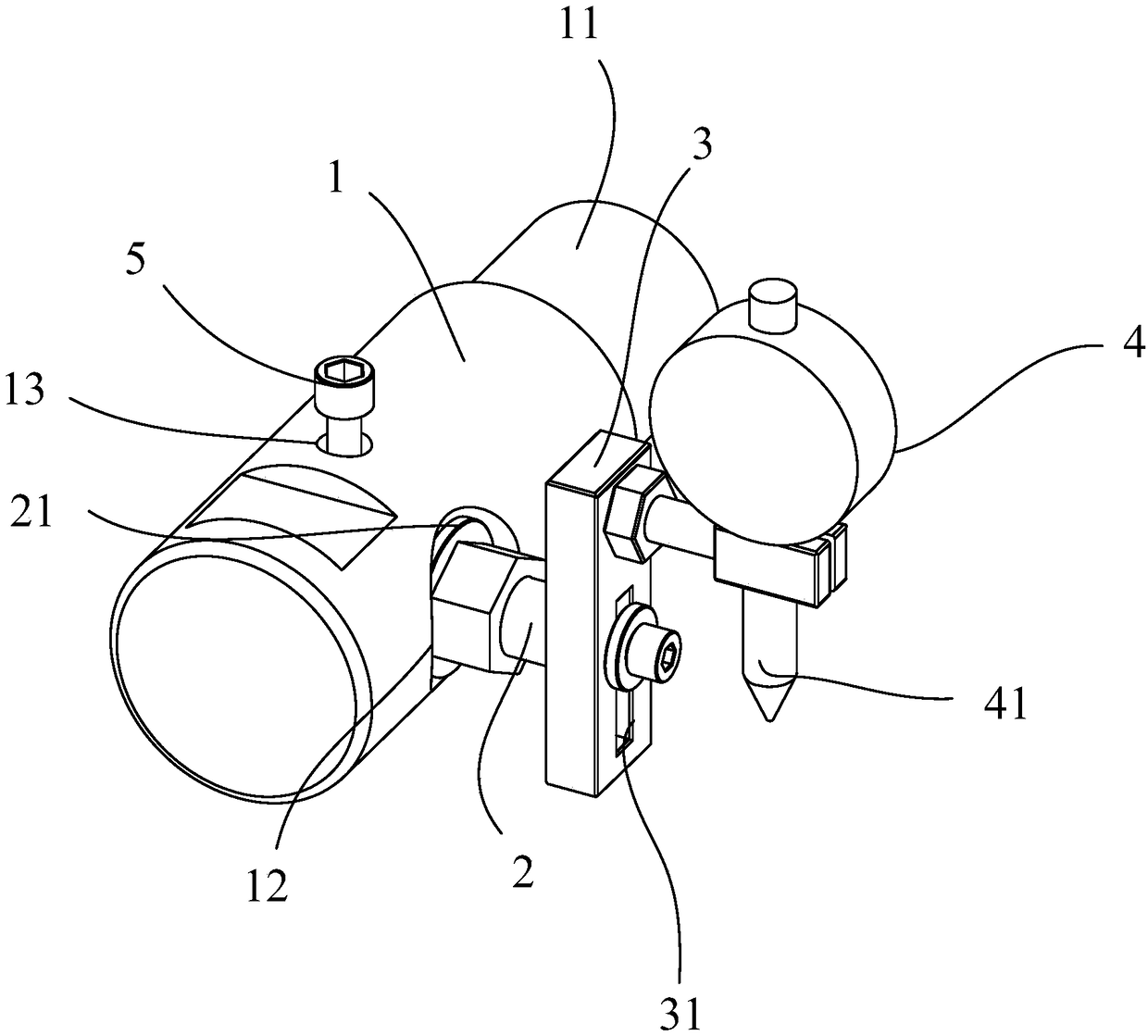

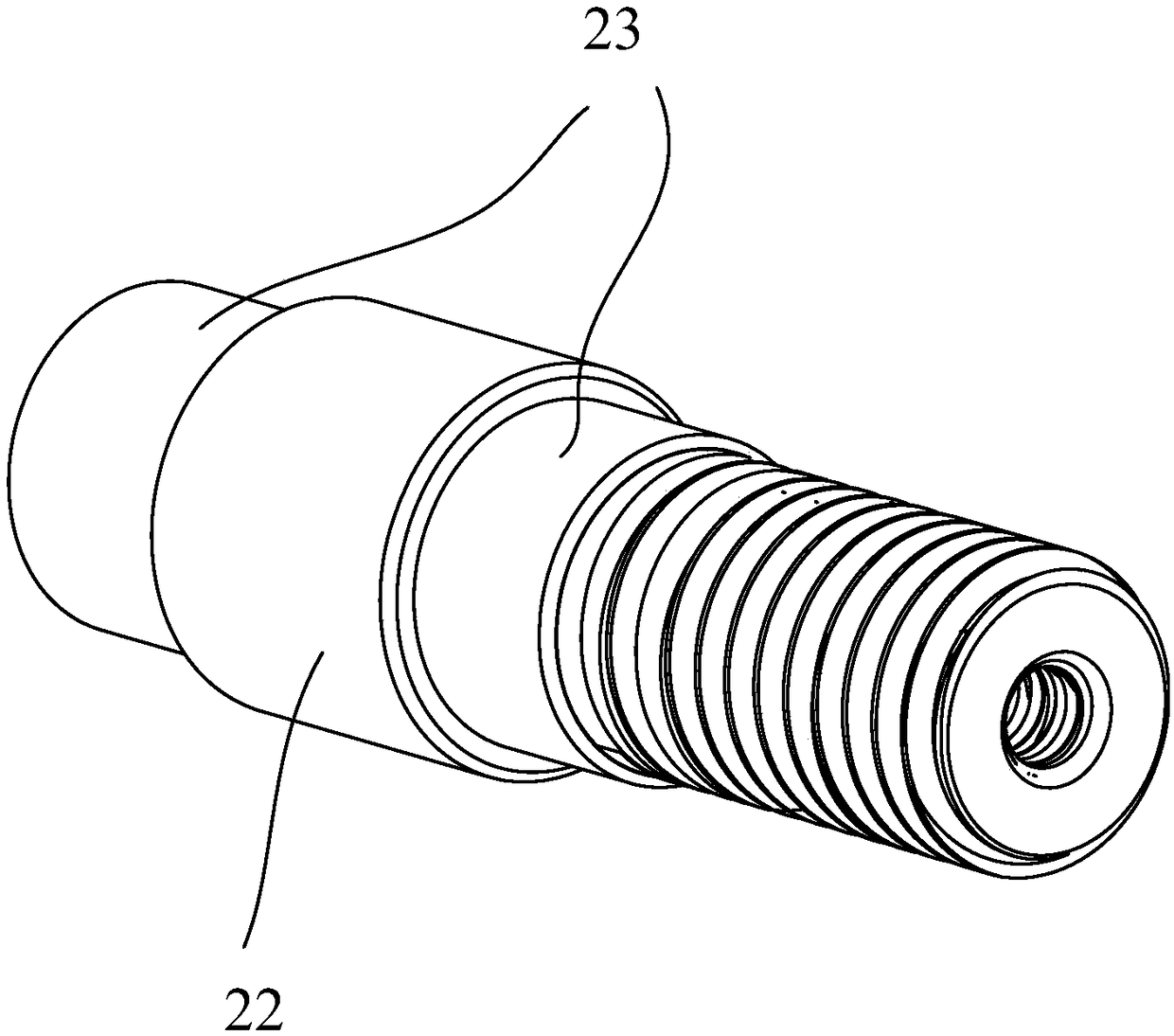

[0031] The power shaft center correction device of the numerically controlled lathe of this embodiment, such as figure 1 with figure 2 As shown, it includes: clamping spindle 1, connecting shaft 2, fixed frame 3 and dial indicator 4, clamping spindle 1 includes clamping part 11 and rotation hole 12, the axis of clamping part 11 and the axis of rotation hole 12 The axis is vertical and in the same plane, the connecting shaft 2 is installed in the rotating hole 12, the connecting shaft 2 can rotate in the rotating hole 12, the connecting shaft 2 is coaxial with the rotating hole 12, and the fixed frame 3 fixes the dial indicator 4 on the On the connecting shaft 2 , the dial indicator 4 has a gauge rod 41 , the dial gauge 4 can translate along the axis of the gauge rod 41 , and the axis of the gauge rod 41 is perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com