Concealed necking precision tubing ring cutting machine

A built-in, precision tube technology, applied in metal processing and other directions, can solve the problems of frequent replacement of shrinking nozzles and difficult control of dimensional accuracy, and achieve the effects of saving machine adjustment time, easy product quality, and good concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

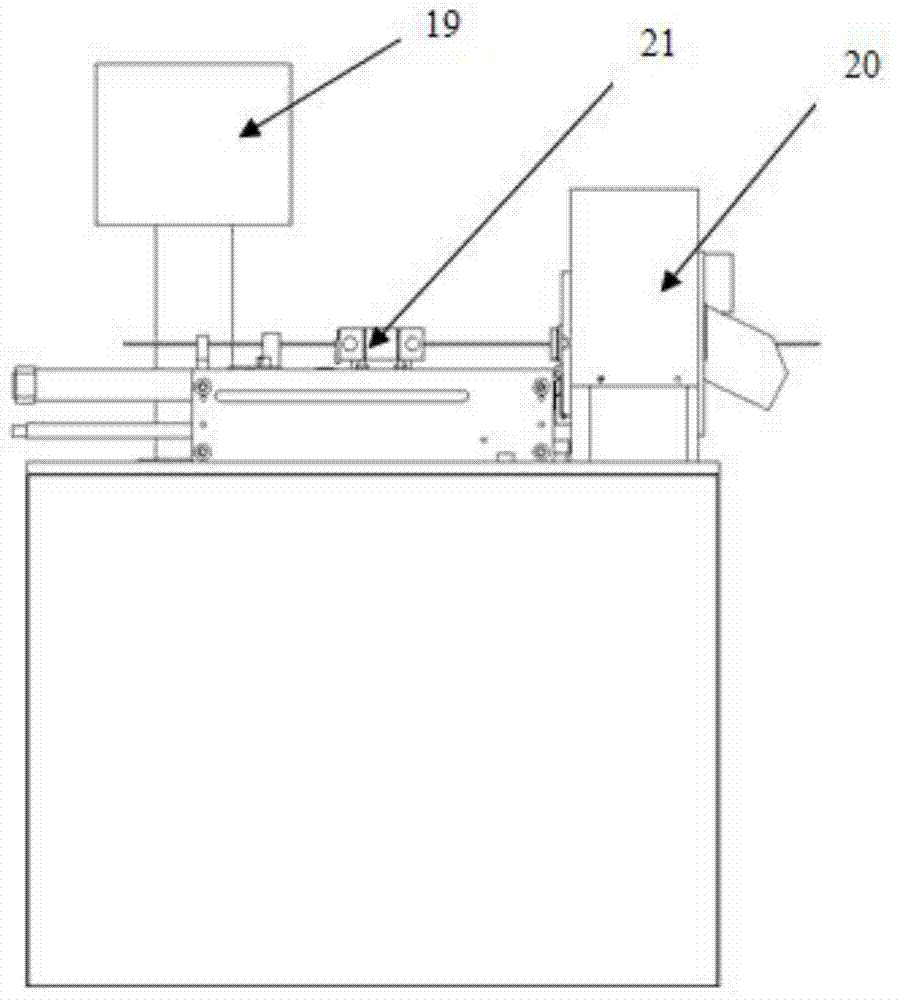

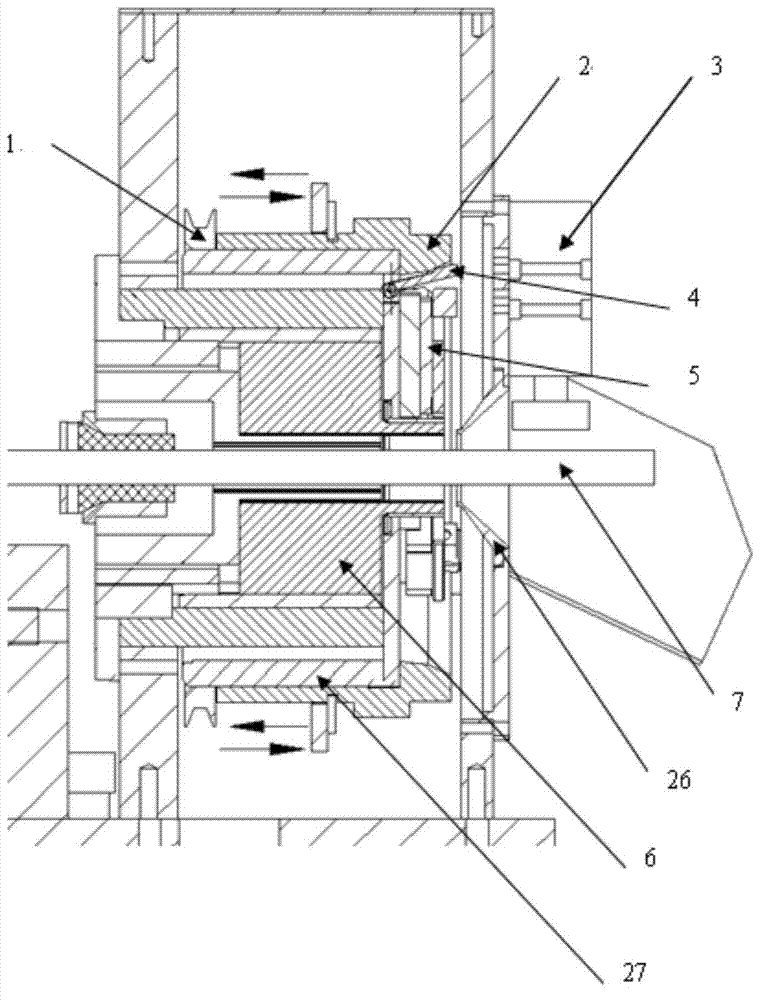

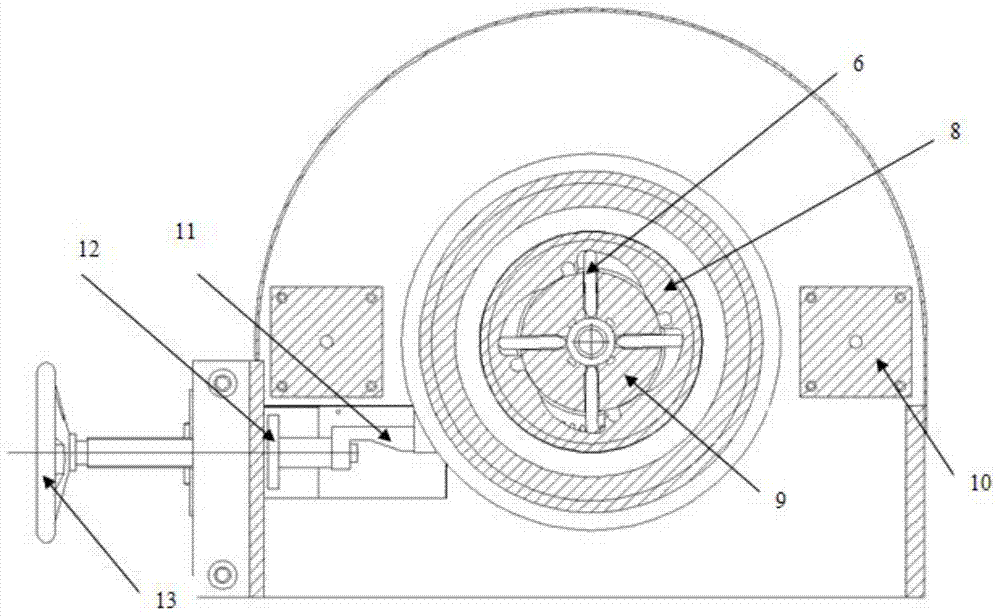

[0017] Such as Figure 1-3 As shown, a built-in shrinking nozzle precision pipe ring cutting machine in this embodiment includes a frame body 22; it is characterized in that: the frame body 22 is provided with a control interface 19, a built-in shrinking nozzle Ring cutting composite assembly 20 and feeding mechanism assembly 21; a feeding mechanism 21 is installed behind the built-in nozzle ring cutting composite assembly 20; a nozzle diameter adjustment screw 23 is also included, and the nozzle diameter adjustment The screw rod 23 is equipped with a mouth-reducing caliber adjustment hand wheel 13, the front end of the adjustment screw rod 23 is connected with the straight rack reciprocating power cylinder 12, and the cylinder rod of the straight r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com