Methods and apparatus for manufacturing metal components with ceramic injection molding core structures

A ceramic core and component technology, applied in the field of investment casting, can solve problems such as corrosion, forming process limitations, oxidation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] While preferred embodiments of the invention have been shown and described herein, it will be obvious to those skilled in the art that these embodiments are given by way of example only. Various modifications, changes and substitutions will occur to those skilled in the art without departing from the scope of the present invention. It should be understood that various alternatives may be made to the embodiments of the invention described herein in practicing the invention.

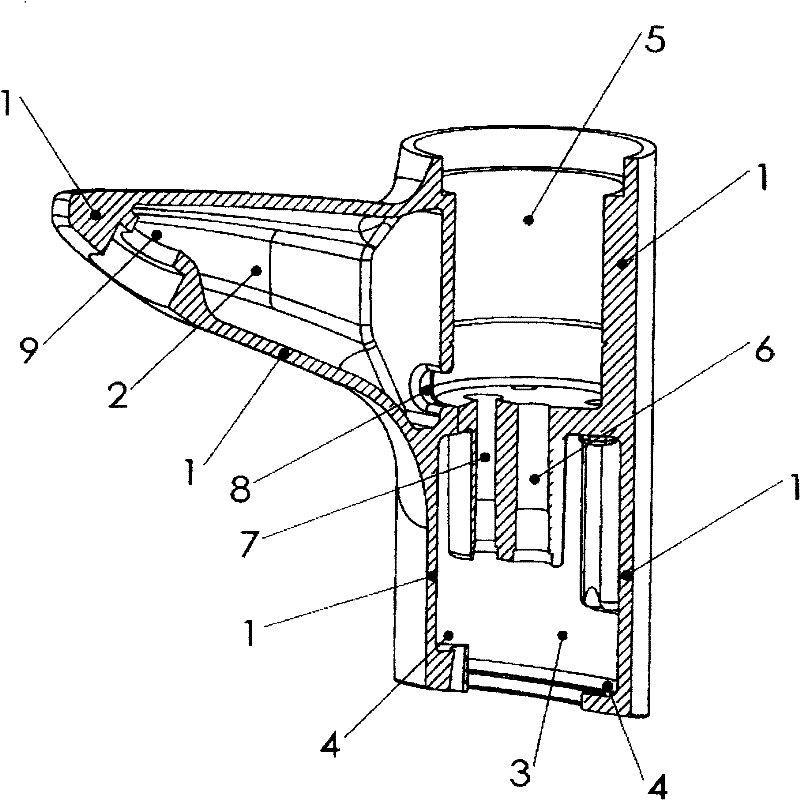

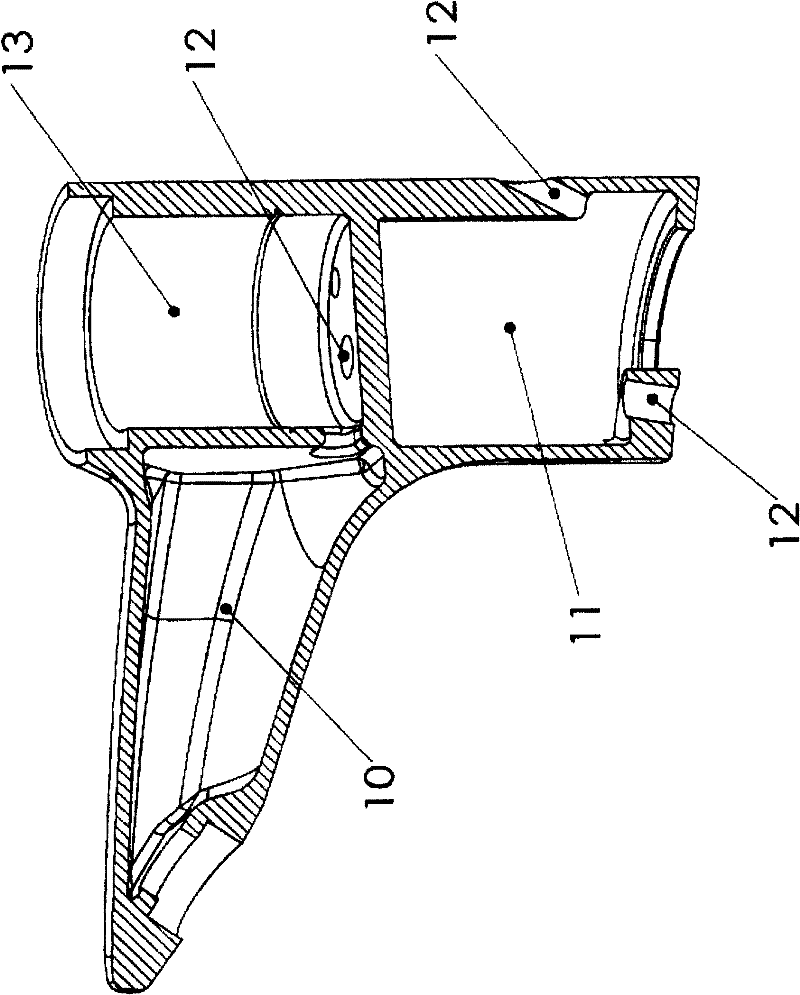

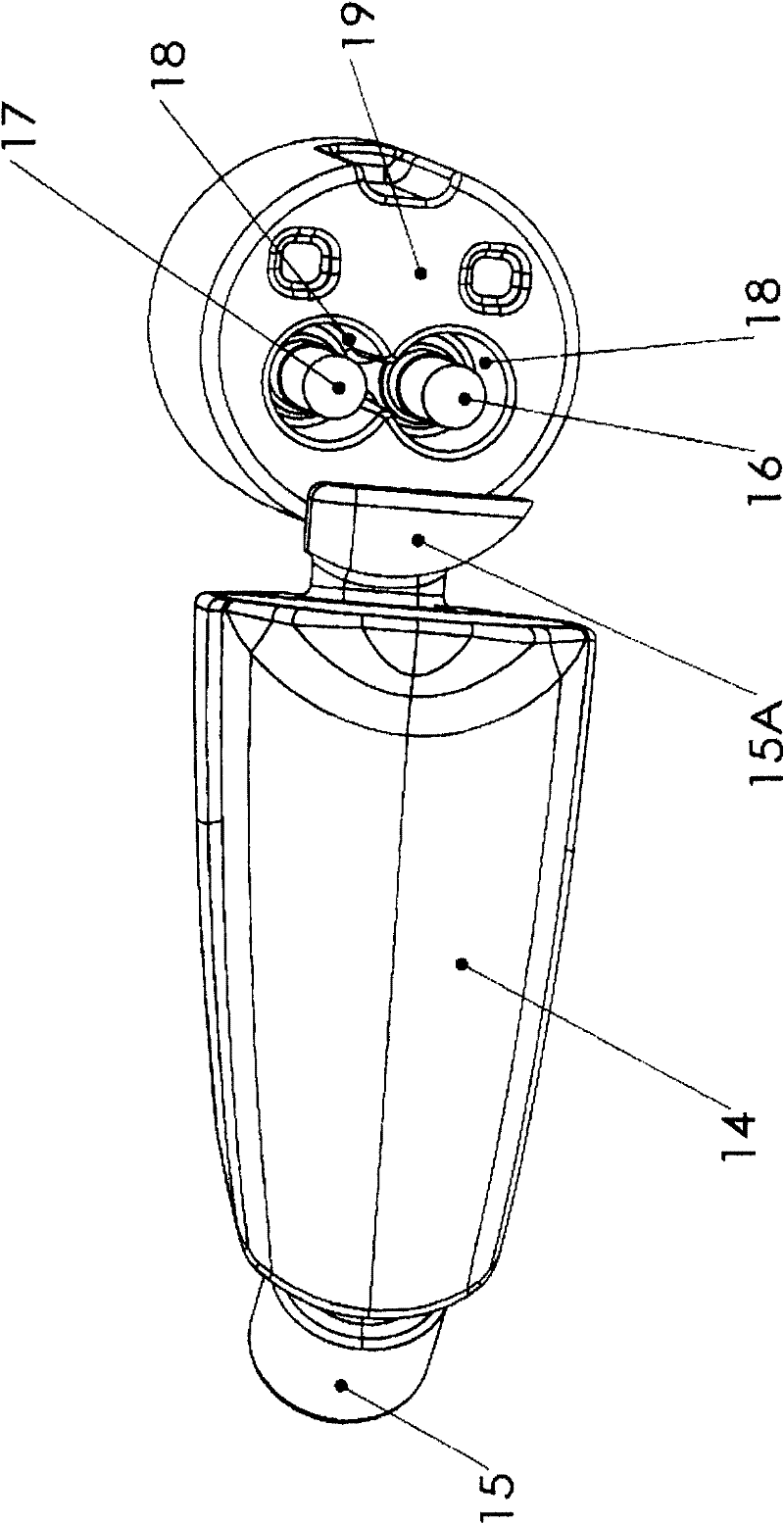

[0023] figure 1 A stainless steel tap body that can be manufactured according to the invention is shown. In some embodiments, the faucet may have the body 1 as a seamless one-piece stainless steel faucet. A one-piece faucet may be integrally formed, formed in a single process step, formed without forging, or formed without grinding. The body may be formed by investment lost wax or lost foam casting. Shaping by investment casting can have many advantages. For example, investment casting may enab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com