Design method of a slider-type cross cardan shaft used for high torque

A cross cardan shaft and design method technology, which is applied in the design field of cross cardan shafts used in slider type high torque, can solve the problems of fork head wear, low bearing capacity, shortened service life, etc., so as to reduce wear and improve The effect of long service life and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

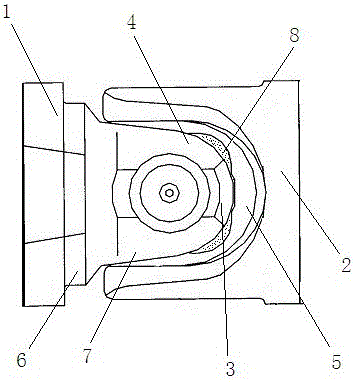

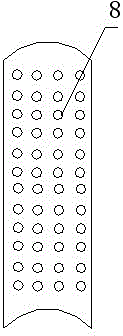

[0012] In order to improve the lubricity of the cross cardan shaft, reduce wear and increase bearing capacity, this embodiment provides a figure 1 The cross universal joint shaft used for the slider type high torque shown includes the first universal joint yoke 1 and the second universal joint yoke 2 which are connected to each other, and the first universal joint yoke 1 protrudes through the right end of the first universal joint yoke Part 3 extends into the recessed part 4 of the left end of the second universal joint yoke 2 and is connected with the bottom surface 5 of the recessed part 4; and the diameter of the neck 6 of the first universal joint yoke 1 is greater than the diameter of its body 7 ; On the bottom surface 5 of the recessed part 4, a groove or latent pit 8 for placing lubricant is provided.

[0013] By providing a lubricant between the contact surfaces of the universal joint yokes, the wear is reduced and the service life is improved. At the same time, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com