Combined necking die

A shrinking die, combined technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of scratches, the surface of the die cannot be replaced by itself, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

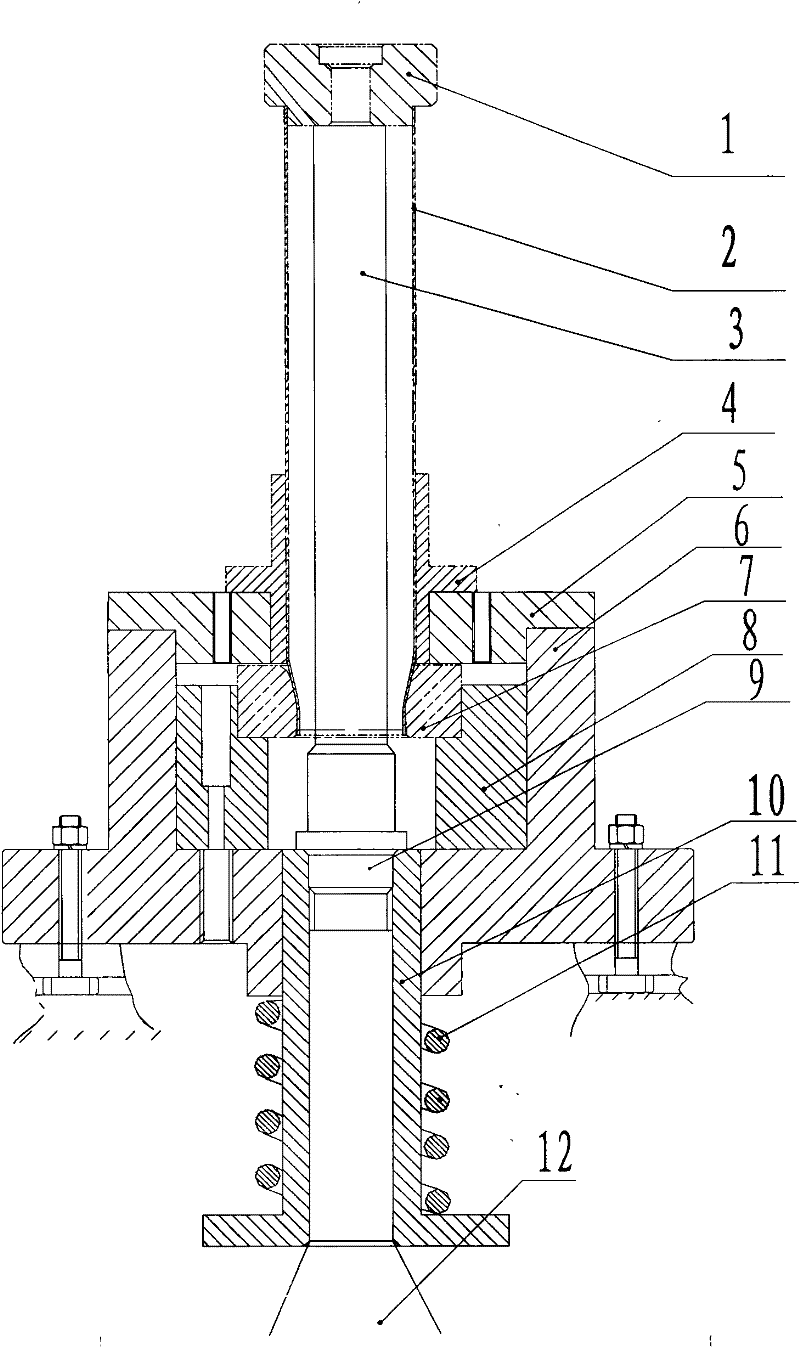

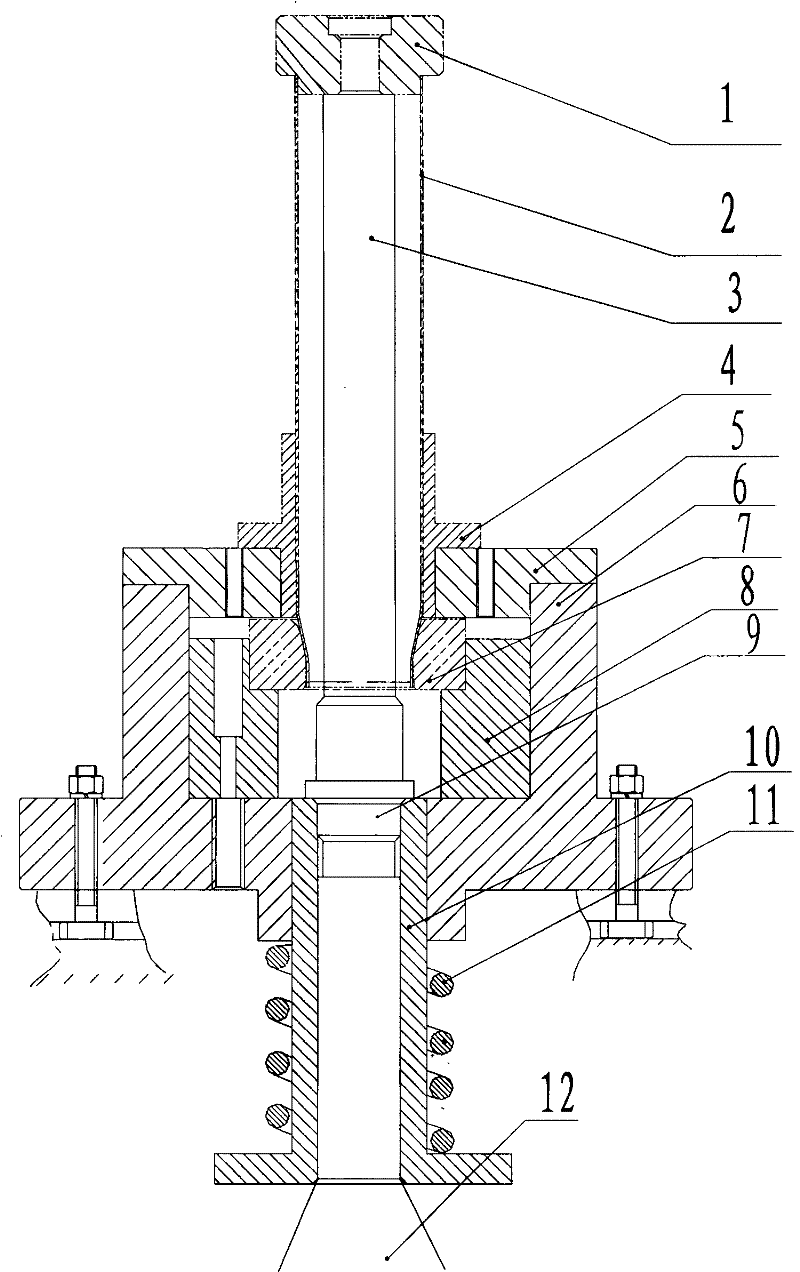

[0008] As shown in Figure 1, the combined shrinking die includes a pressure sleeve 1, a mandrel 3, a guide sleeve 4, a positioning plate 5, a lower mold base 6, a die 7, a die sleeve 8, a stripper block 9, a guide block 10 and The spring 11, the lower mold base 6 is fixed on the pressure equipment, the mold sleeve 8, the die 7, the positioning plate 5 are loaded into the lower mold base 6, the guide block 10, the spring 11, and the material return block 9 form the material return mechanism, and the core Axle 3 is fastened with pressing sleeve 1, and the inner diameter of guide sleeve 4 is the same as the outer diameter of cylindrical material 2, and the shape and size of die 7 are the same as the diameter reduction shape and size. The ejection mechanism is that the spring 11 is set outside the guide block 10, the ejection block 9 is placed between the guide block 10 and the die 7, the bottom and outside of the positioning plate 5 are close to the lower die base 6, and the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com