Positioning technology for runner blade of propeller turbine

A runner blade and slurry water technology, applied in the field of runner blade positioning technology, can solve the problems of difficult positioning and clamping, high labor intensity, complicated operation, etc., and achieve good tooling versatility, low labor intensity, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

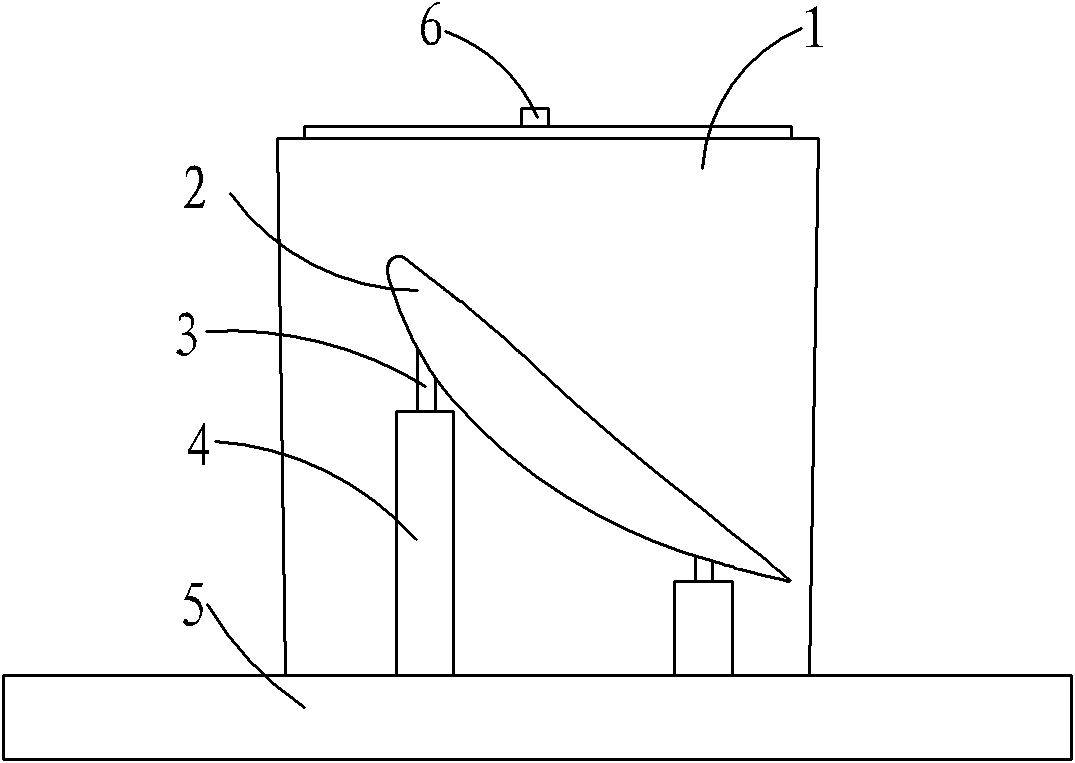

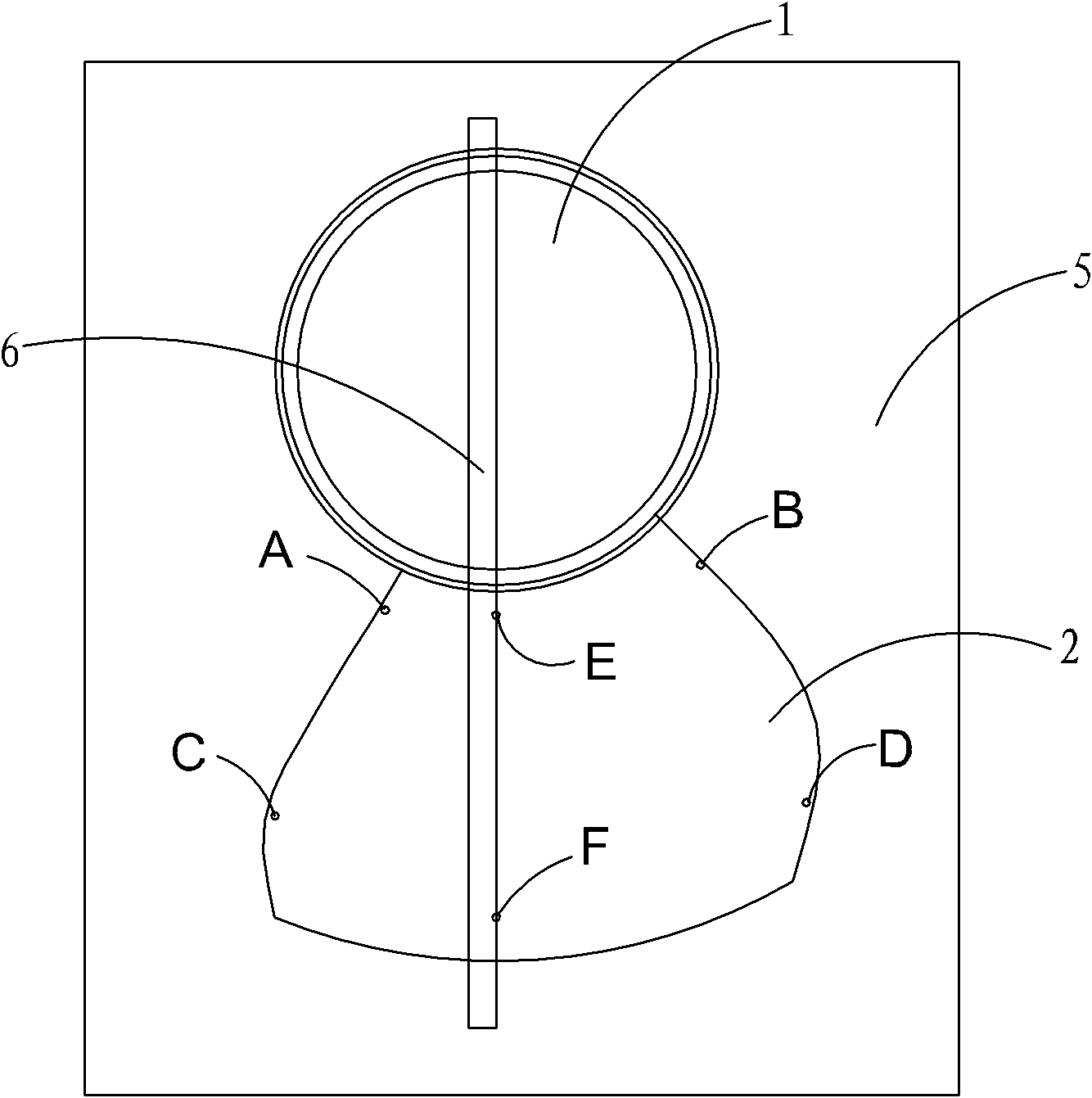

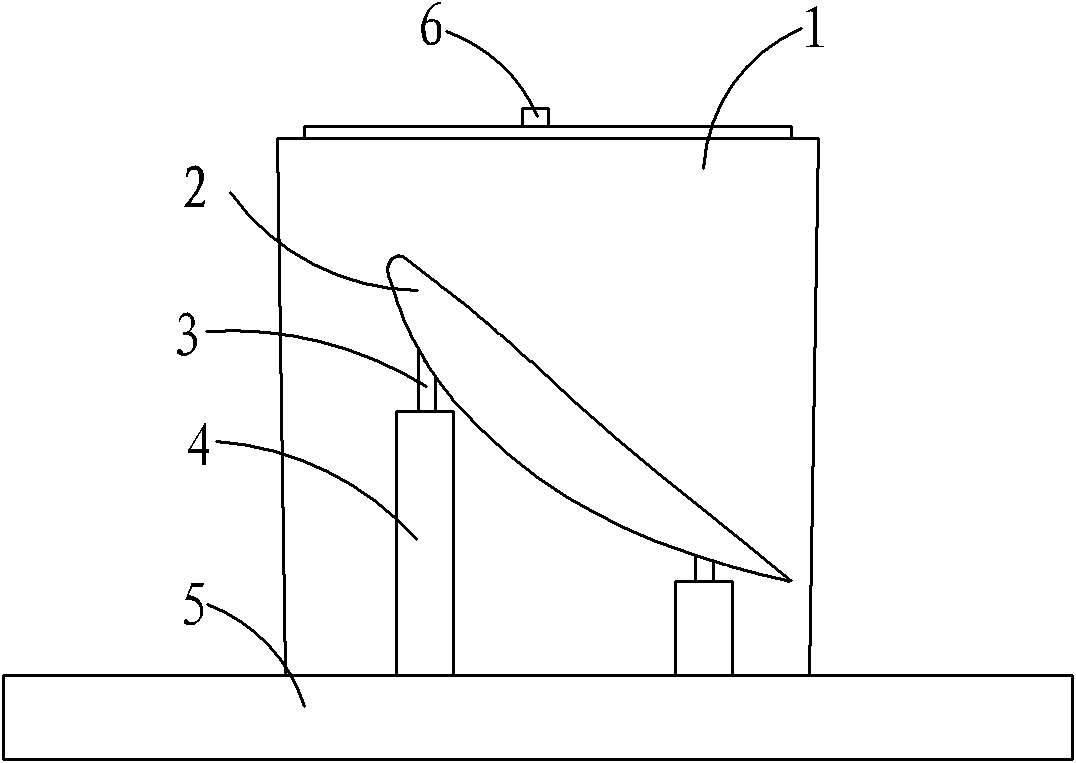

[0017] Please also see figure 1 with figure 2 As shown, the positioning process of the runner blade of the axial-flow fixed-pitch turbine includes the following steps:

[0018] Step 1: Carve out the alignment points E and F of the blade rotation centerline on the front of the blade 2. The alignment points E and F are the vertical projections of the rotation centerline of the blade 2 on the front of the blade 2 according to the placement angle specified in the design drawing;

[0019] Step 2: After milling the back of the blade 2, spot-weld four process positioning round bars 3, and mill out positioning planes of different heights on the end faces of the round bars;

[0020] Step 3: The hub 1 is placed on the assembly platform 5, and four bases 4 of appropriate sizes are distributed according to the positions of the hub 1 and the blade 2 where the round steel 3 is located;

[0021] Step 4: Place the blade 2 on the base 4 for profile positioning;

[0022] Step 5: Place a squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com