Universal tool for stabilizing treatment of belleville spring

A technology of stabilization treatment and disc springs, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of lack of universal tooling, inability to effectively deal with the actual production of disc springs in small batches and multiple varieties, and achieve universal tooling. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present application will be described in further detail below through specific implementation methods and accompanying drawings.

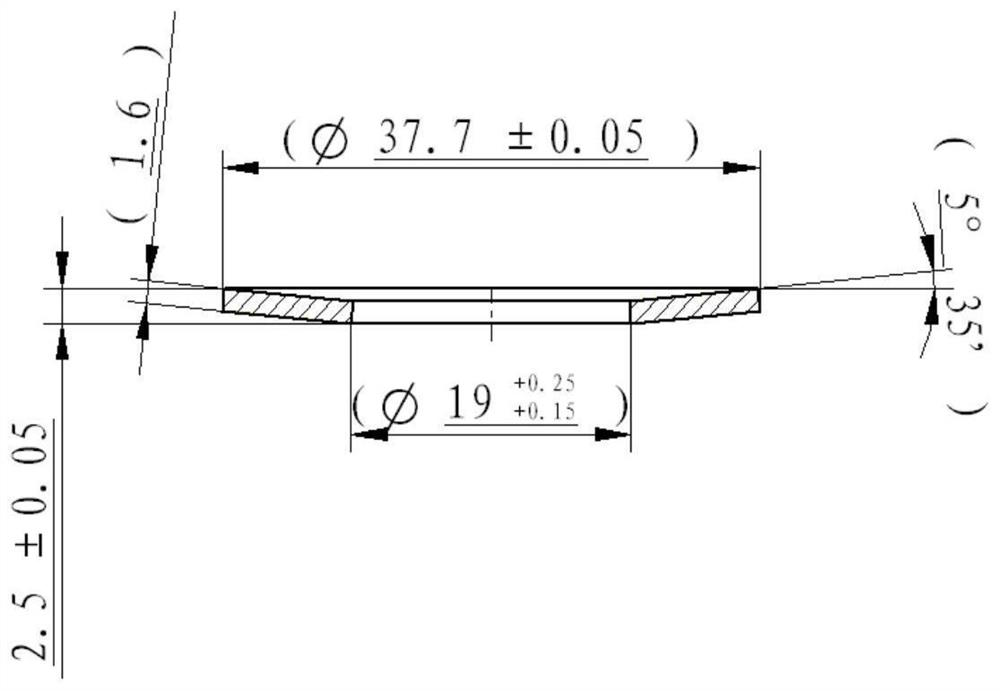

[0025] The present invention provides a disc spring stabilization treatment universal tool for disc springs with an outer diameter of ≤70mm after flattening, which is used to cope with the production of small batches and multi-variety disc springs that require a large number of special tooling for stabilization treatment Condition.

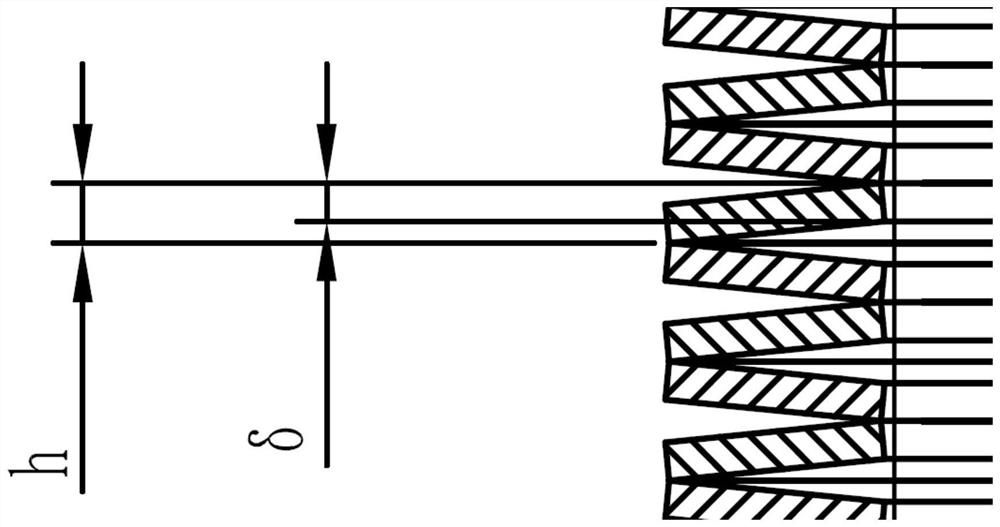

[0026] The present invention adopts combined tooling, equipped with special spacer rings and pressure rings, and regulates the stabilization of several disc springs through the number of spacer rings.

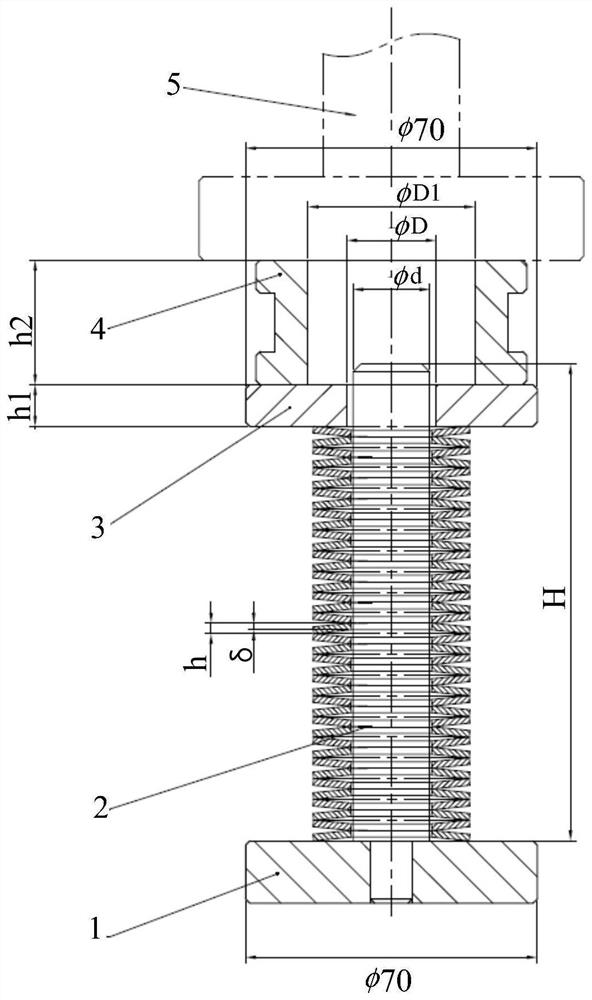

[0027] See figure 1 , which is a structural schematic diagram of a general tooling for disc spring stabilization treatment provided by the present invention. The tooling is a combined tooling, and the tooling includes: a base 1 , a guide mandrel 2 , a spacer ring 3 and a pressure ring 4 . The base 1, the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com