Porous burner as well as a method for operating a porous burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

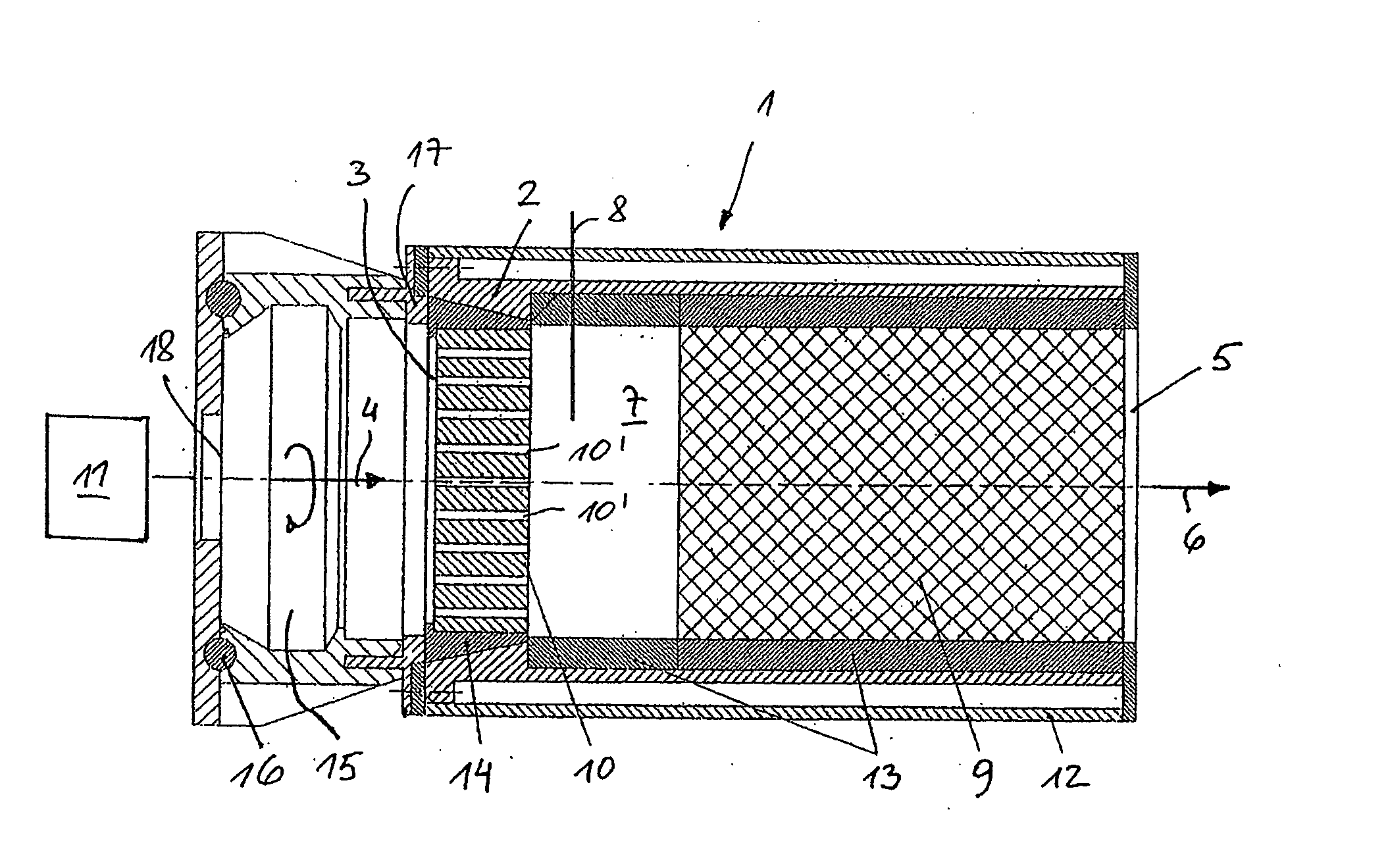

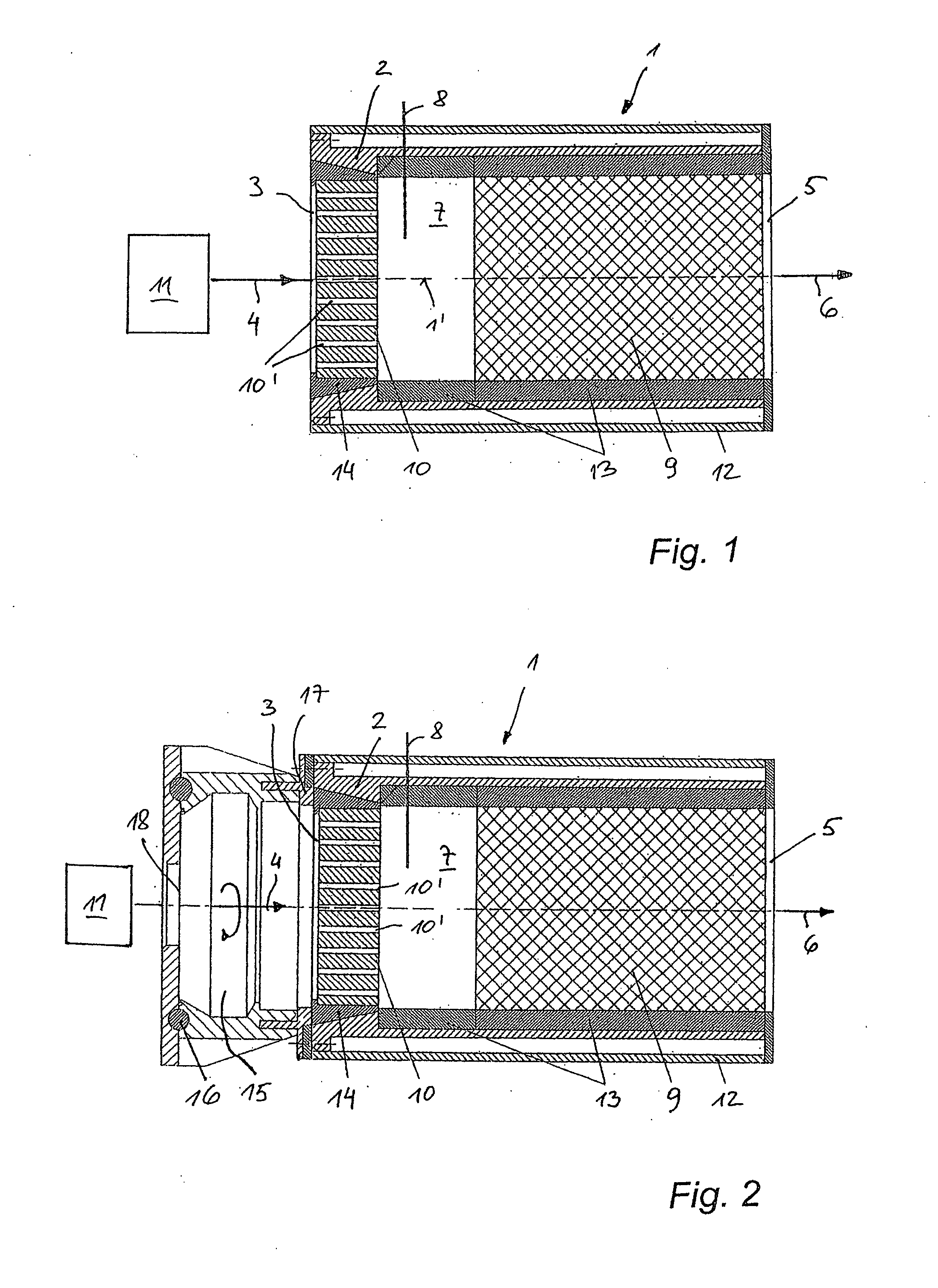

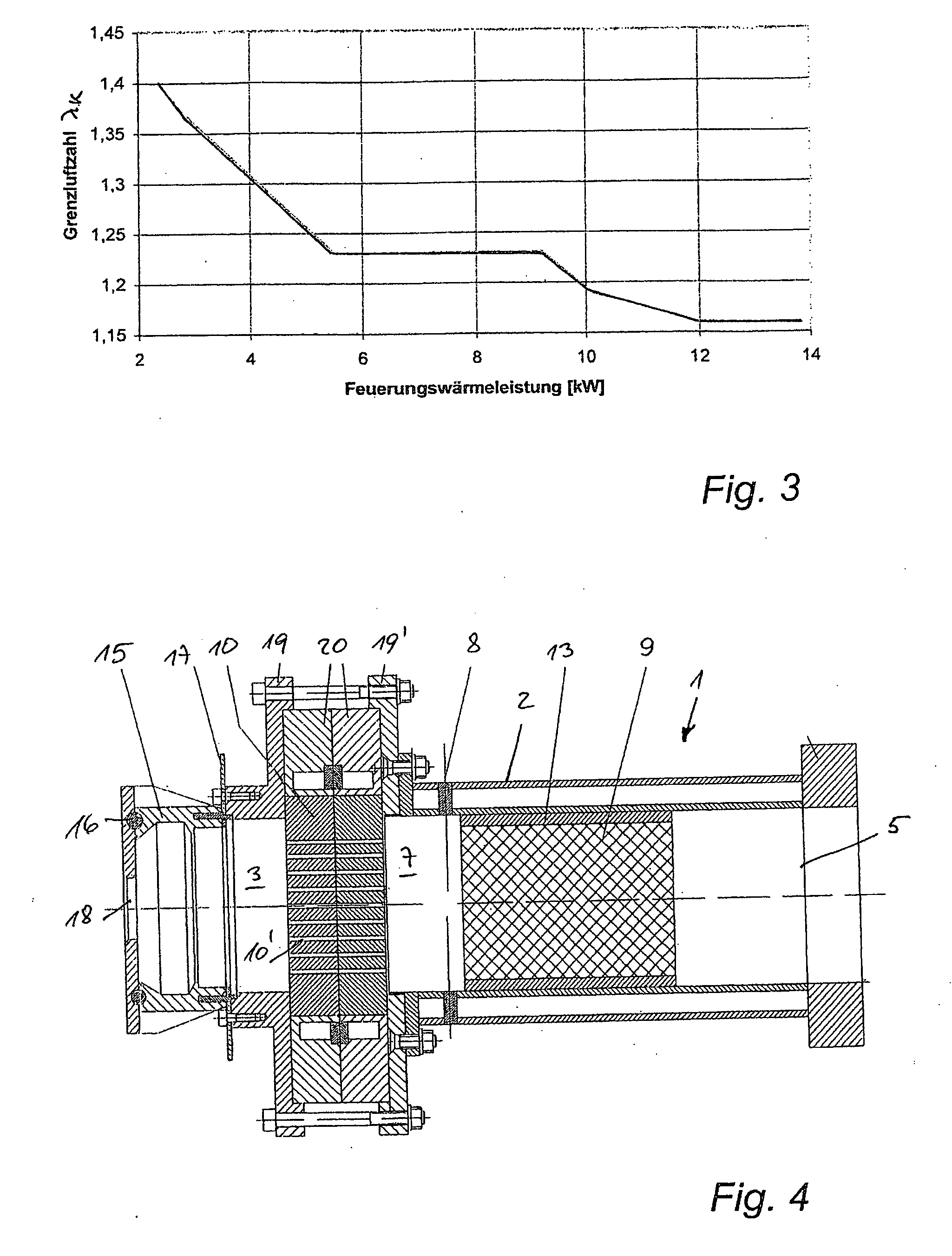

[0036]The porous burner shown in FIG. 1 (for instance, a gas burner) has a housing 2 with an inlet 3 for a fuel-air mixture 4 and an outlet 5 for the exhaust gas mixture 6 generated in the burner, where in flow direction of the process gases there is provided in the housing 2 an ignition space 7 with an ignition device 8 followed by a ceramic porous medium 9. The ignition space 7 is bounded on the inlet side by a stabilizing element 10, a perforated ceramic plate, which reduces the inlet cross-section and redirects the flow of the fuel-air mixture 4 in such a way that it is perpendicular to the inlet cross-section of the porous medium 9. In the example shown, which is a cylindrical porous burner, the fuel-air mixture is directed parallel to the axis 1′ of the porous burner 1. The porous burner 1 furthermore is provided with a device 11 for controlling the mass flow of the fuel-air mixture 4, for instance a pressure blower in front of the burner or a suction fan behind the burner. Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com