Fire channel separating apparatus of anode baking stove

A furnace fire path and roasting technology, which is applied in the field of anode roasting furnace fire path partition device, can solve the problems of bulky structure of the anode roasting furnace fire path gate plate, inadaptability to high-temperature deformation of the fire path, and increased roasting production cost, etc. The effect of product quality, simple structure, and reduced smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

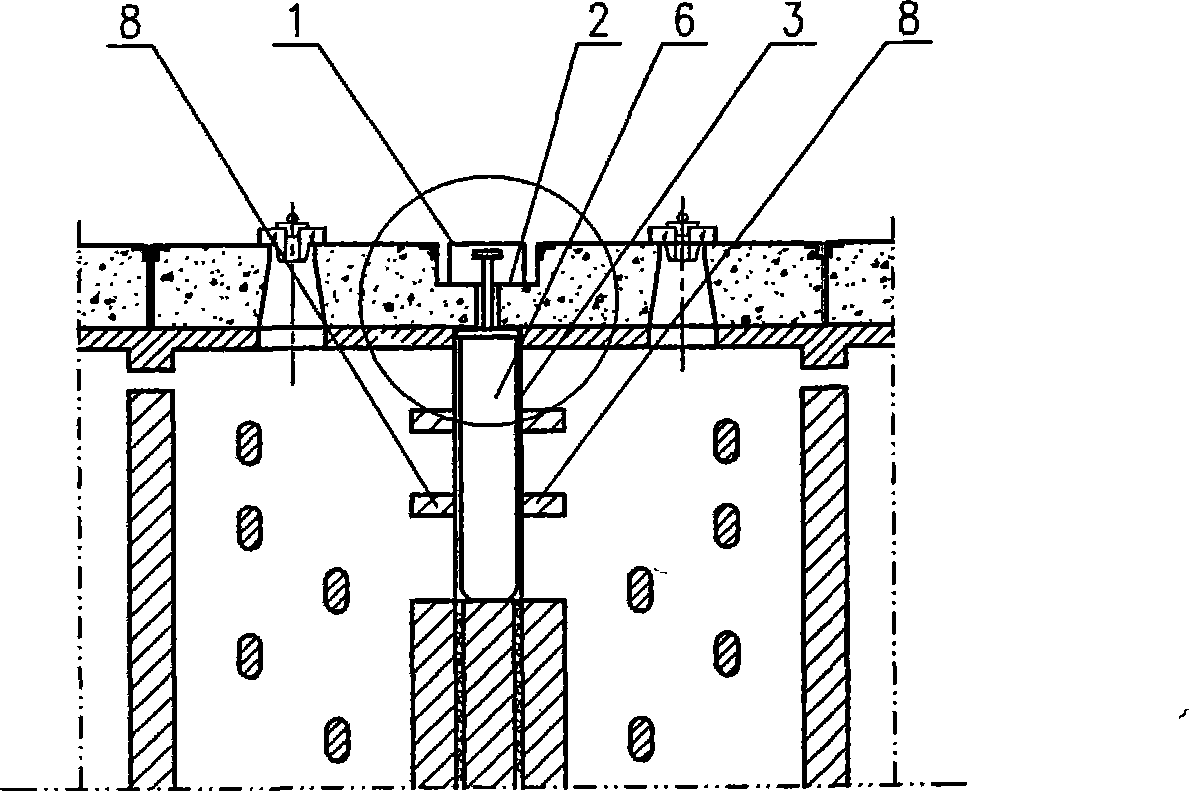

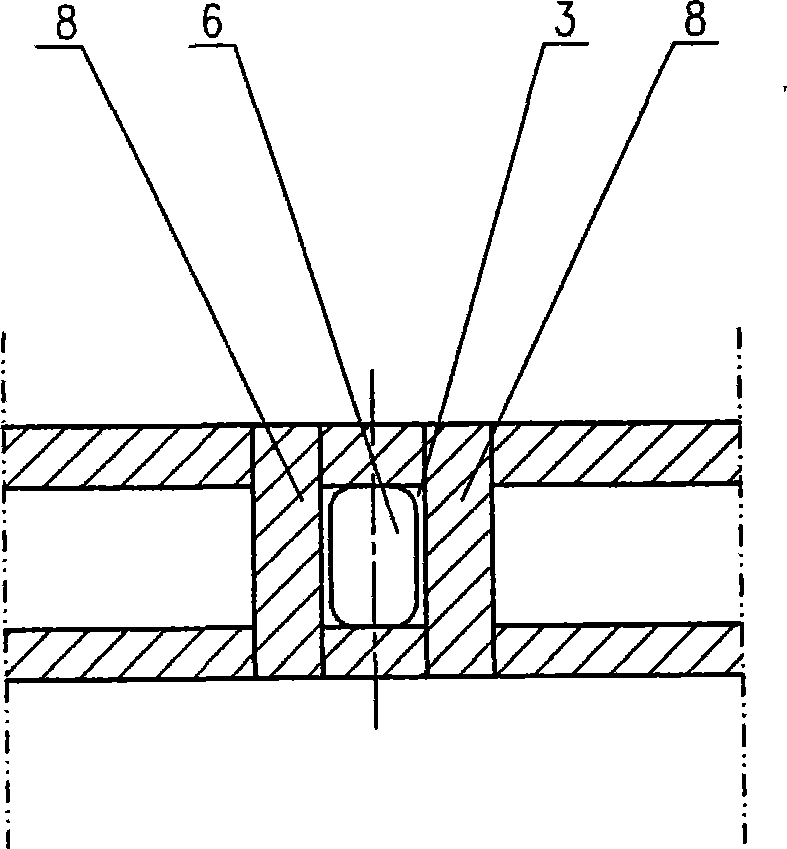

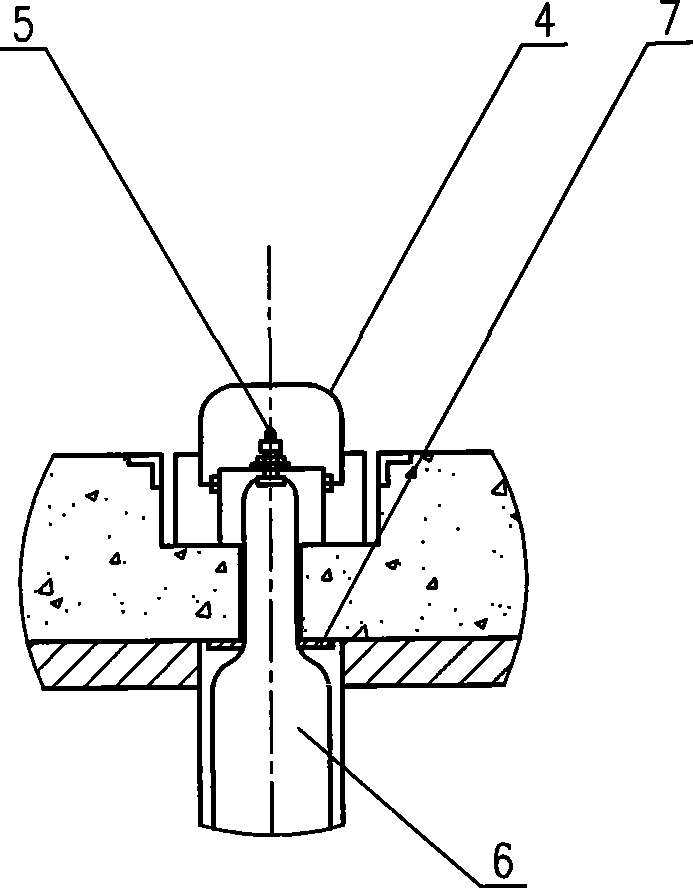

[0027] Such as Figure 1-3 Shown in the present invention is an anode roasting furnace fire path isolation device, which is used to isolate the operating furnace chamber at the low temperature end of the flame system from the non-operating furnace chamber outside the flame system. On the channel at the intersection of the cross wall and the fire channel between the furnace chambers, and between the two rows of positioning pull bricks 8, a furnace surface operation hole 2 is provided. The operation hole 2 is provided with an operation hole cover 1, and the furnace surface operation hole 2 The channel between the furnace chambers below is provided with an isolated part 3, and a sealed air bag 6 is arranged in the isolated part 3, and the sealed air bag 6 communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com