Method for producing microemulsified fuel oil

A production method and microemulsion technology, applied in the field of fuel oil, can solve problems such as not being perfect, and achieve the effects of simple equipment, reduced carbon deposition, and wide sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

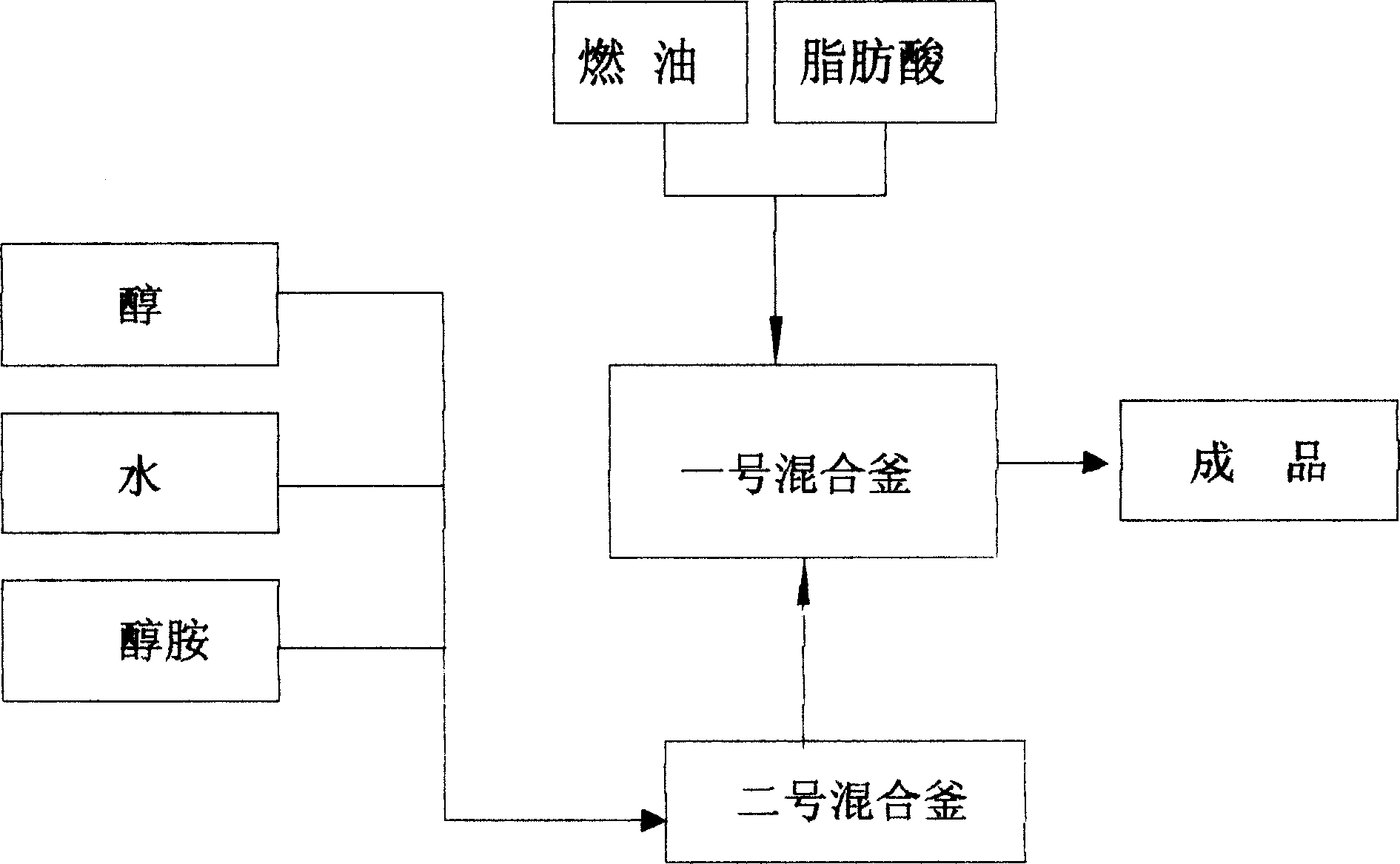

[0007] Embodiment 1, under normal temperature, under normal pressure, fatty acid is 26% by weight ratio, and diesel oil is 47%, drops into No. 1 mixing tank and mixes, stirs 3-4 minute; Under normal temperature, normal pressure, water is by weight ratio 9.5%, methanol 14.8%, and triethanolamine 2.7% are put into No. 2 mixing tank and mixed, and stirred for 3-4 minutes; The liquid is then mixed and stirred, so that the mixed liquid changes from milky white to transparent brown liquid, that is, the finished product of micro-emulsion diesel oil is produced. Fatty acid is the fatty acid produced from the leftovers after soybean oil extraction.

Embodiment 2

[0008] Embodiment 2, under normal temperature, under normal pressure, by weight ratio, fatty acid is 30%, and diesel oil is 48%, drops into No. 1 mixing tank and mixes, stirs 3-4 minute; Under normal temperature, normal pressure, by weight ratio, water is 9.6%, 9.6% ethanol, 2.8% diethanolamine into the No. 2 mixing tank and mix, and stir for 3-4 minutes; put the mixed solution in the No. 2 mixing tank into the No. The liquid is then mixed and stirred, so that the mixed liquid changes from milky white to transparent brown liquid, that is, the finished product of micro-emulsion diesel oil is produced. Fatty acid is the fatty acid produced from the leftovers after peanut oil extraction.

Embodiment 3

[0009] Embodiment 3, under normal temperature, under normal pressure, by weight ratio, fatty acid is 35%, and diesel oil is 40%, drops into No. 1 mixing tank and mixes, stirs 3-4 minute; Under normal temperature, normal pressure, by weight ratio, water is 14.5%, 8% propanol, and 2.5% diethanolamine are put into No. 2 mixing tank and mixed, and stirred for 3-4 minutes; The mixed liquid is then mixed and stirred to make the mixed liquid change from milky white to transparent brown liquid, that is, to produce a micro-emulsified diesel product. Fatty acid is the fatty acid produced from the leftovers after oil extraction of rapeseed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com