Automatic fire-leading igniting device and igniting method for biomass briquette

A technology of briquetting fuel and biomass, which is applied in the combustion method, combustion ignition, incandescent ignition, etc., can solve the problems of unsuitable briquetting fuel, changing electrode discharge characteristics, explosion of molding material, etc., to reduce ignition time and soot emission, Effects of reduced smoke and dust content and reduced ignition energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

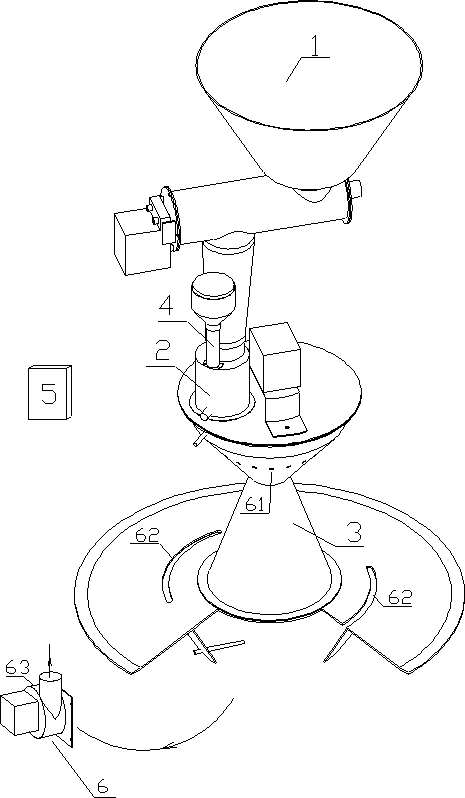

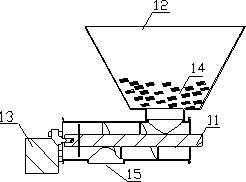

[0037] see Figure 1-Figure 4 , the present invention includes a feeding device 1, an ignition chamber 2, a main combustion device 3, an ignition device 4, a control device 5, and a smoke exhaust device 6, the feeding device 1 is located above the ignition chamber 2, and the ignition chamber 2 is located at the main combustion device 3 Above, the ignition device 4 is located above the ignition chamber 2.

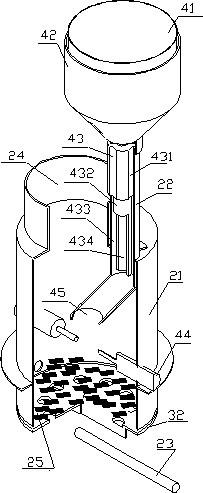

[0038]The ignition device 4 includes a DC motor 41, a blower fan 42, an electric heating device 43, a high-voltage discharge needle 44, an ignition tube 22 and a hot air outlet 45, and the electric heating device 43 is located in the ignition tube 22, and the ignition tube 22 Located above the ignition chamber 2 , the air outlet velocity range of the ignition tube 22 is 1.9-2.3m / s, and the high-voltage discharge needle 44 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com