Construction method for support mould with large-curvature spherical concrete structure

A technology of concrete structure and construction method, which is applied in the direction of arched structure, dome structure, formwork/formwork/working frame, etc., to achieve the effect of cost saving, less mold making material and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

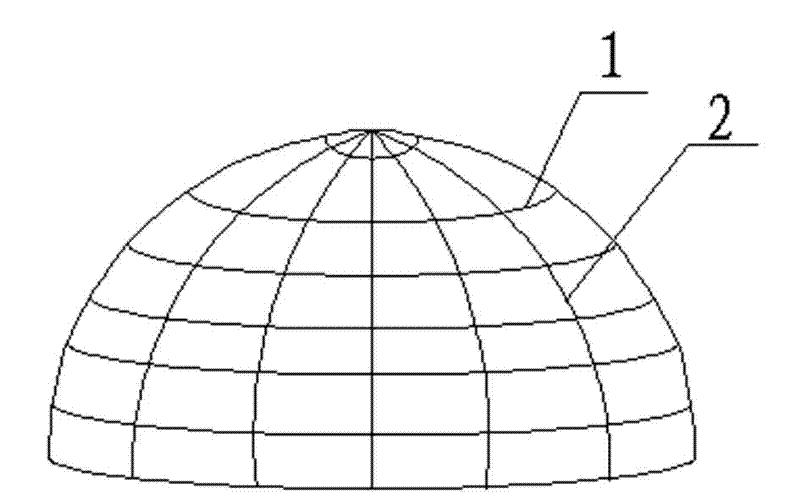

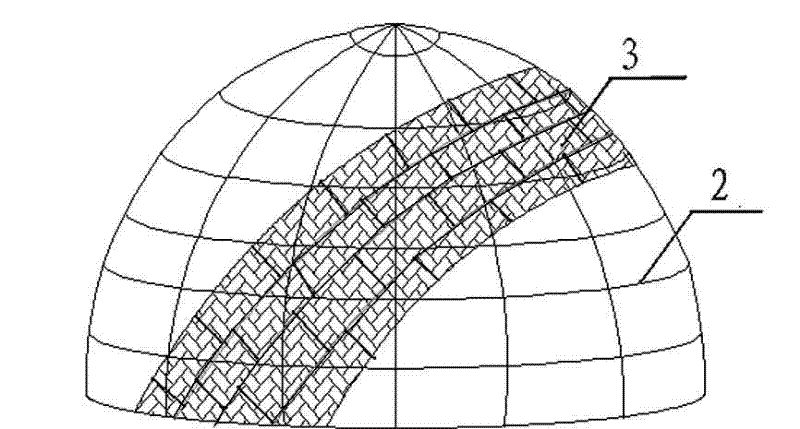

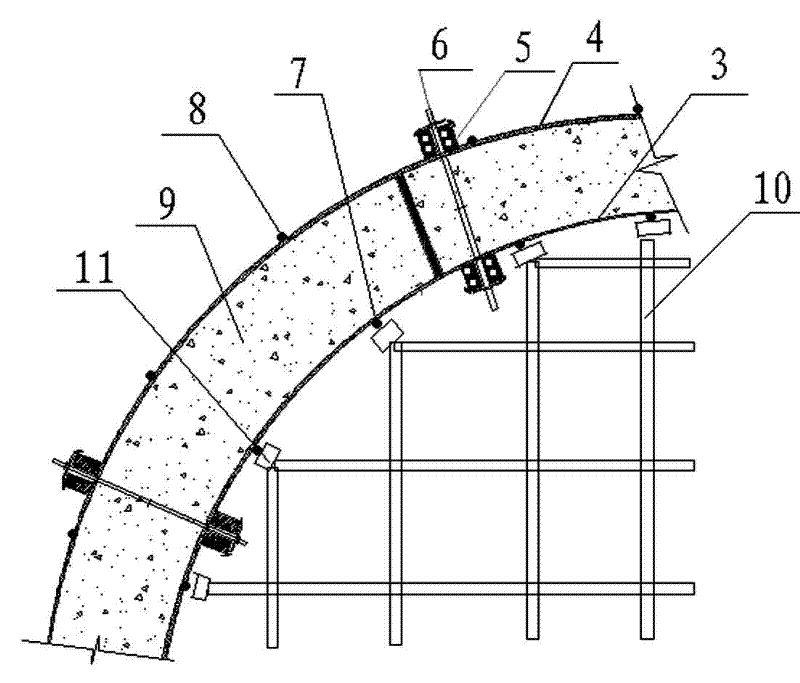

[0011] like figure 1 , 2 As shown in , 3, a large curvature spherical concrete structure formwork construction method, at first utilize warp direction reinforcement 2 and weft direction reinforcement 1 to intersect and fix to make inner spherical reinforcement cage 7, the distance between two adjacent latitude direction reinforcement bars 2 is 500- 800mm, then adopt five-ply board or 8mm thick bamboo plywood, cut into width 200mm, length 2000-3000mm inner formwork unit 3, then install some inner formwork units 3 on the cage surface of inner spherical steel bar 7, inner formwork unit 3 and weft direction Reinforcements intersect obliquely and are connected by steel wires; supporting square timbers 11 and supporting steel pipes 10 are arranged under the inner spherical reinforcement cage 7 to form a supporting system to increase the bearing capacity of the formwork; Outer spherical reinforcement cage 8, the distance between two adjacent latitudinal reinforcements is 500-800mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com