Coarse sapphire bushing LED and its making method

A sapphire substrate and light-emitting diode technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low light extraction efficiency and limited luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

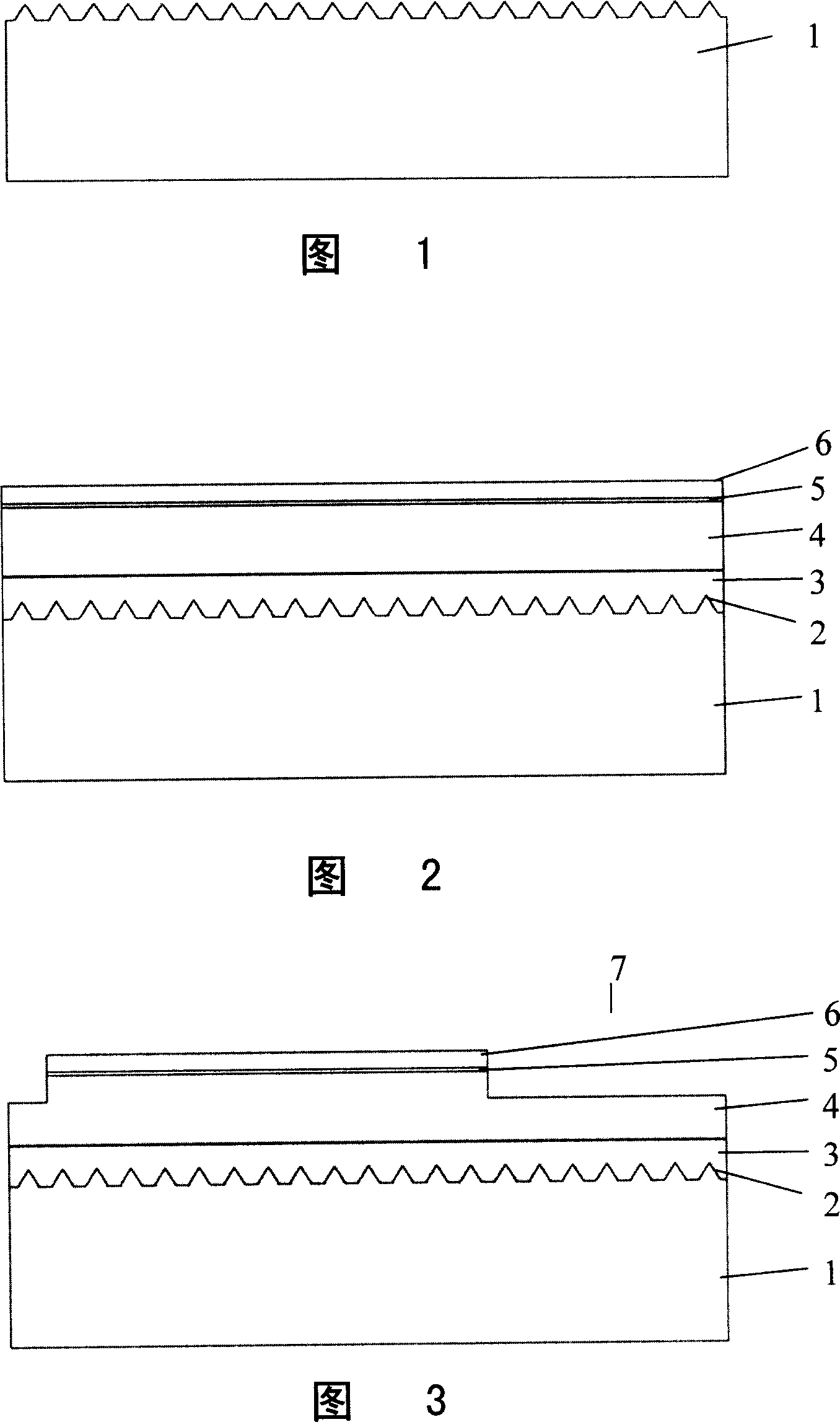

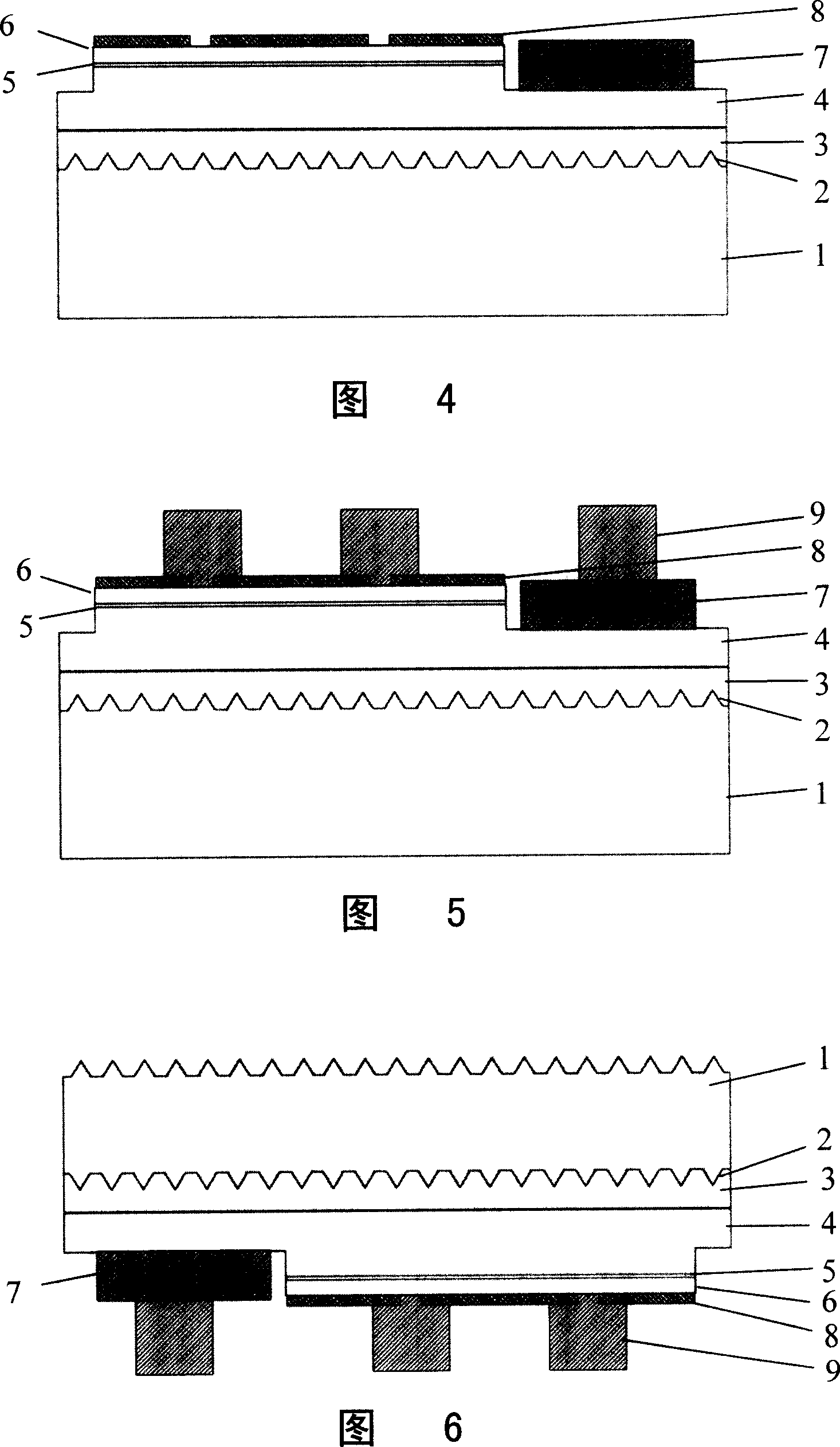

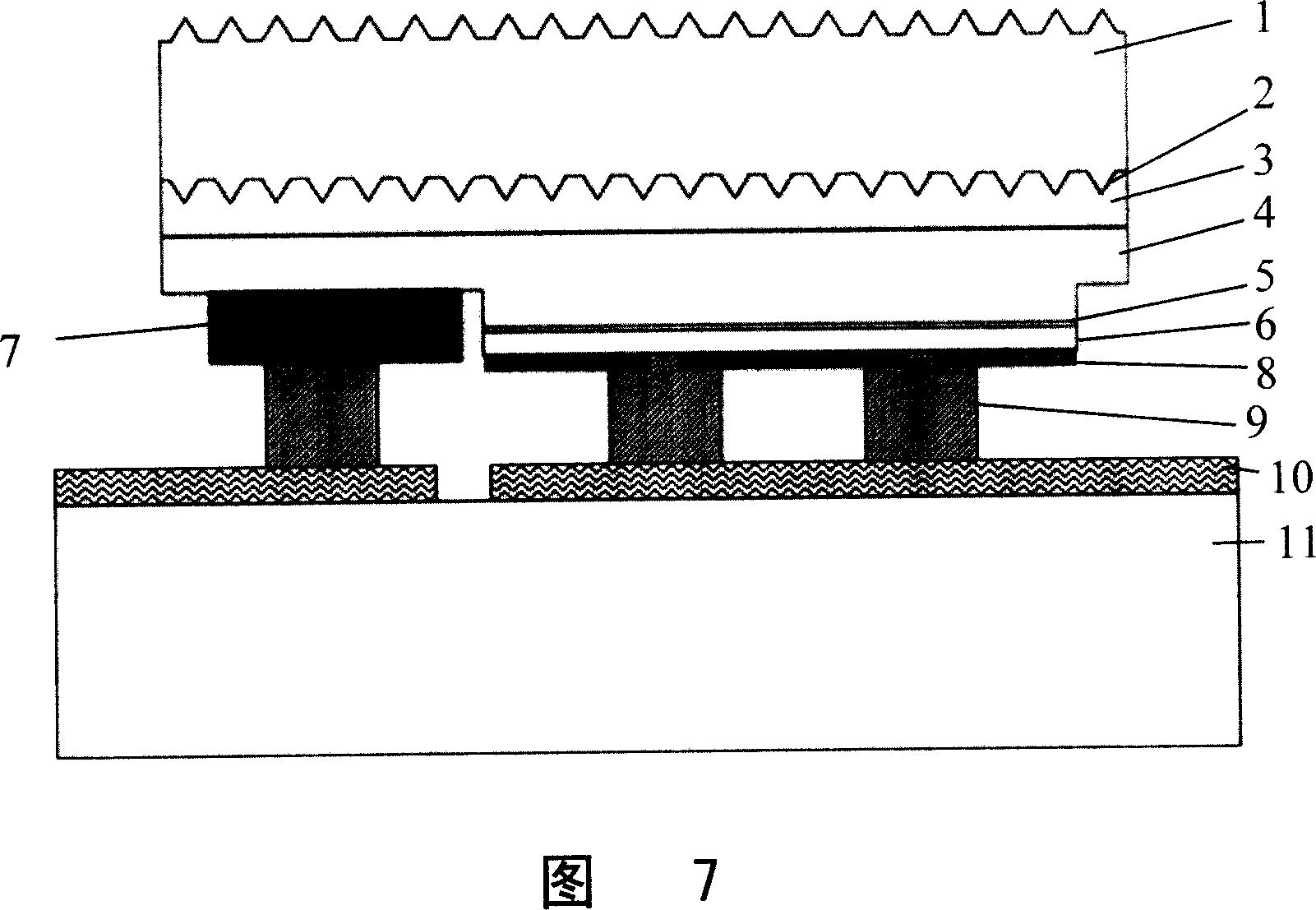

[0022] The embodiment of the present invention will be specifically described below with reference to FIG. 1 to FIG. 7 .

[0023] Fig. 1 shows a longitudinal cross-sectional view of a roughened sapphire substrate of the present invention. The structure and manufacturing method are described in detail below.

[0024] The roughened pattern of the sapphire substrate 1 is formed by wet etching the substrate covered with a silicon dioxide mask. First deposit a layer of silicon dioxide film on the sapphire substrate 1 (the thickness needs to be greater than 1000 angstroms); then, the pattern window to be made will be made on the silicon dioxide mask by photolithography and etching methods; The substrate 1 with the silicon dioxide mask is etched in a mixture of concentrated phosphoric acid and concentrated sulfuric acid at a temperature above 250 degrees Celsius. By changing the pattern of the silicon dioxide mask and the etching time, the wet etching process can produce a roughene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com