Section-variable metal lattice structure and machining method thereof

A technology of metal lattice and processing method, which is applied in the direction of building components, etc., can solve the problems of many consumables and heavy weight, and achieve the effects of saving powder materials, high specific stiffness, and improving light properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

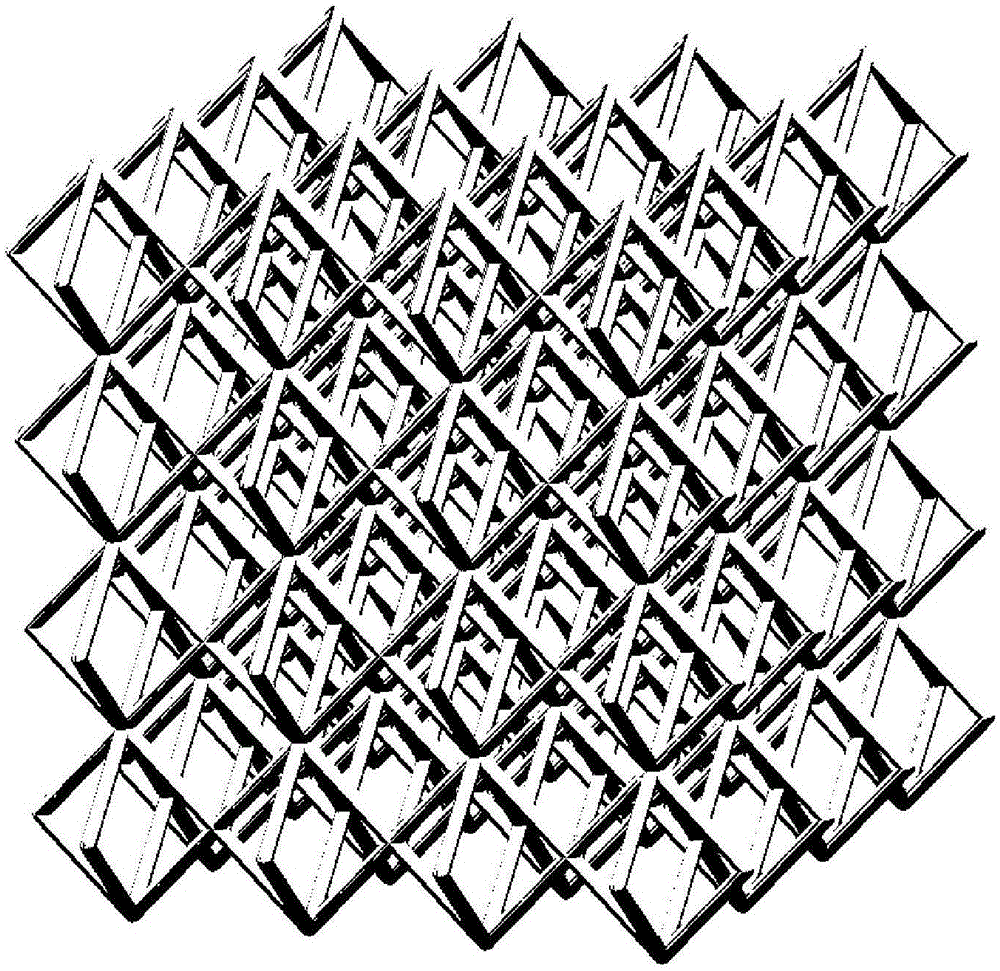

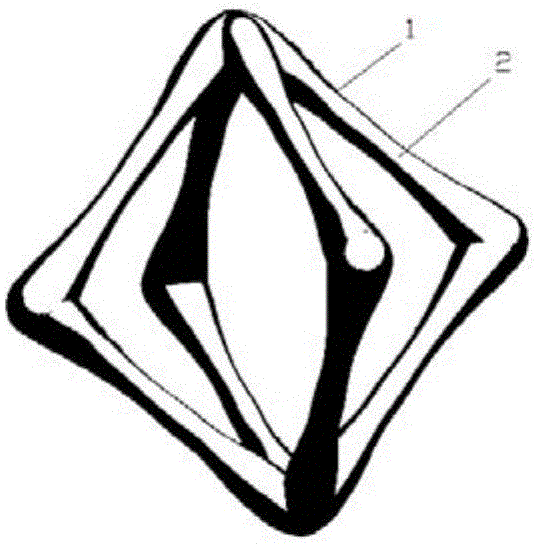

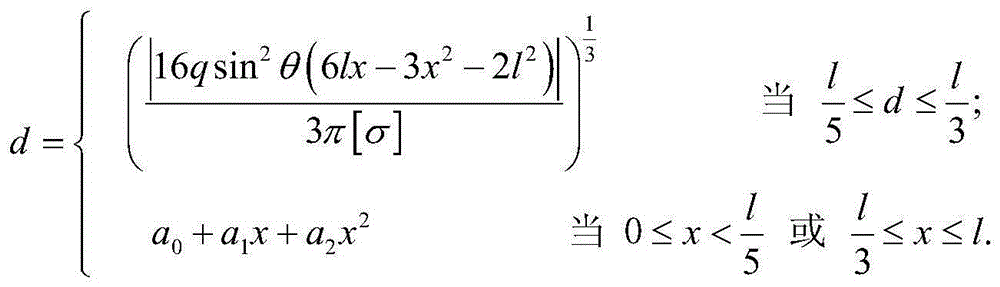

[0019] figure 1 It is a schematic diagram of the variable cross-section metal lattice structure of the present invention; figure 2 It is a structural schematic diagram of a variable-section lattice unit, as shown in the figure: the variable-section metal lattice structure of this embodiment includes a plurality of variable-section lattice units 1 arranged in space; the variable-section lattice unit 1 is composed of a plurality of variable-section lattice units. Cross-section rods 2 are connected, and multiple variable-section lattice units 1 are closely arranged and stacked together in space to form a variable-section metal lattice structure. Optimization makes the variable cross-section rod 2 form a variable cross-section rod 2 with thick ends and a thin middle part, so that the material constituting the variable cross-section rod 2 increases or decreases according to the stress gradient in the variable cross-section rod 2, saving powder materials, Improved mechanical prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com