Process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and system thereof

A technology of superheated steam and lignite, which is applied in the petroleum industry, separation methods, and separation of dispersed particles. It can solve the problems of difficult system regulation, unstable operation, and low safety performance, so as to ensure the drying effect, optimize energy utilization, and save equipment. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

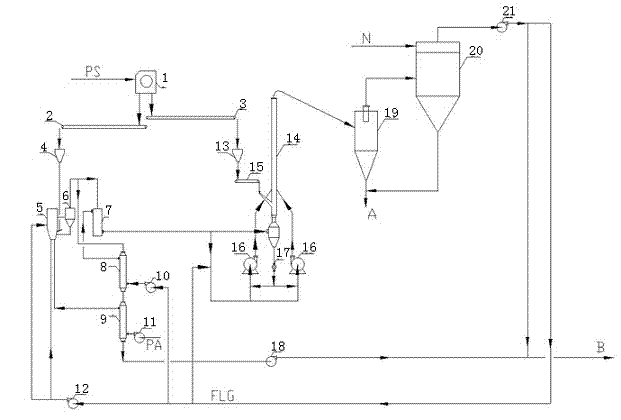

[0040] figure 1 Among them, the technological process of the present invention is:

[0041] Lignite process: The raw lignite is crushed by the crusher 1 into coal lumps / powders less than or equal to 15mm, and the coal lumps / powders to be upgraded are sent to the dry coal bunker 13 through the belt conveyor II2 or the conveying equipment that plays the same role as the waiting Raw material coal of upgrading, all the other briquettes / powder are sent to the furnace front coal bunker 4 as the combustion coal of flue gas generator 5 through belt conveyor II 3 or the conveying equipment that plays the same role. The raw coal to be upgraded comes out of the drying coal bunker 13 and is measured by the weighing belt 15, then enters the drying conveying pipe 14, and fully contacts with the hot flue gas from the bottom of the conveying pipe to realize the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com