Tubular/cylindrical mud residue internal reflux mud-water high-efficiency separation device

A separation device and internal reflux technology, which is applied to the feeding/discharging device, separation method, sedimentation separation and other directions of the sedimentation tank, can solve the problems of insufficient space utilization, easy blockage of the reflux seam, and large floor space. Complete and reasonable energy utilization, lower operating costs, and the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

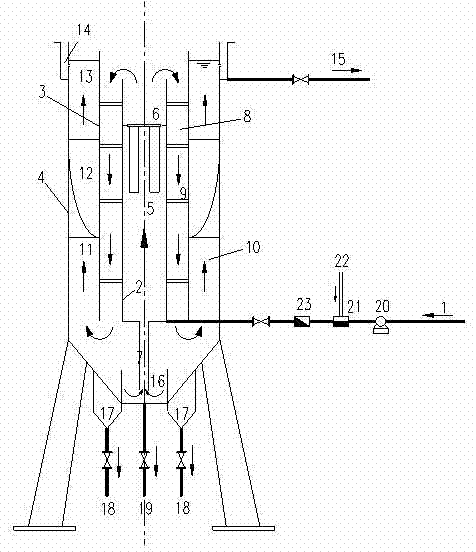

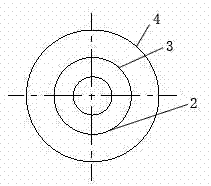

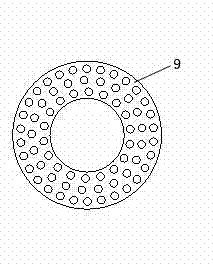

[0029] see figure 1 , figure 2 , image 3 , as can be seen from the figure, the device adopts a cylindrical stainless steel pool body, the upper part is cylindrical, and the lower part is truncated circular. The circular pool is isotropic, and the stress conditions and hydraulic conditions are very good. The interior of the device is mainly composed of mechanical flocculation area 5, hydraulic flocculation area 8, sedimentation area 10, sludge concentration chamber 16, active sludge return pipe / tube 7, small hole grid orifice plate 9 and inclined plate / pipe 12, etc. The exterior is mainly composed of a water inlet pipe 1, an outlet pipe 14, a mud bucket 17, a mud bucket mud discharge pipe 18, an emptying pipe 19 and a pool body.

[0030] The mechanical flocculation zone 5, the hydraulic flocculation zone 8, and the sedimentation zone 10 are concentric and separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com