Skeleton type cable

A skeleton and skeleton technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of large cable damage and difficult identification, and achieve the effect of simple production, effective protection, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

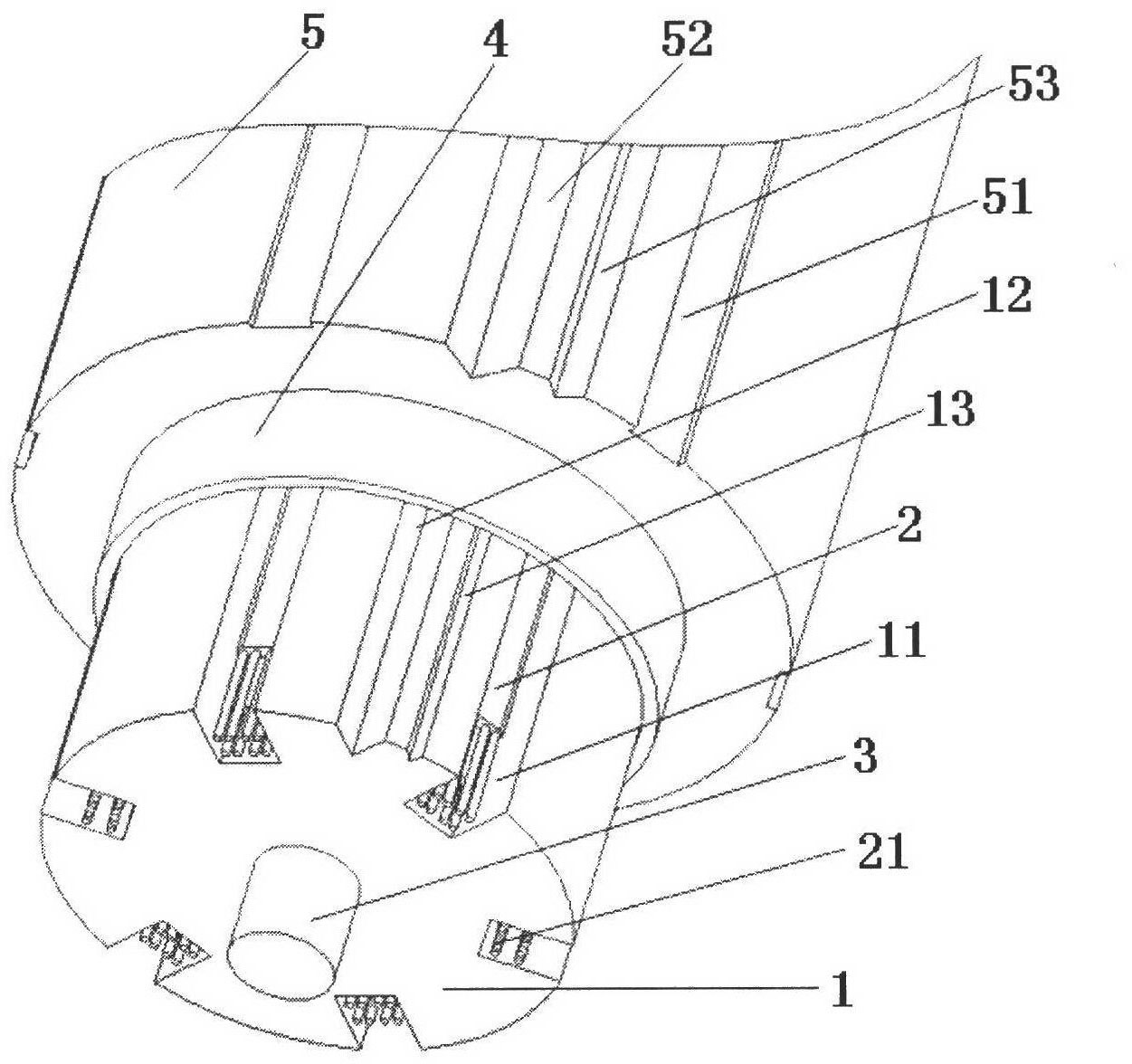

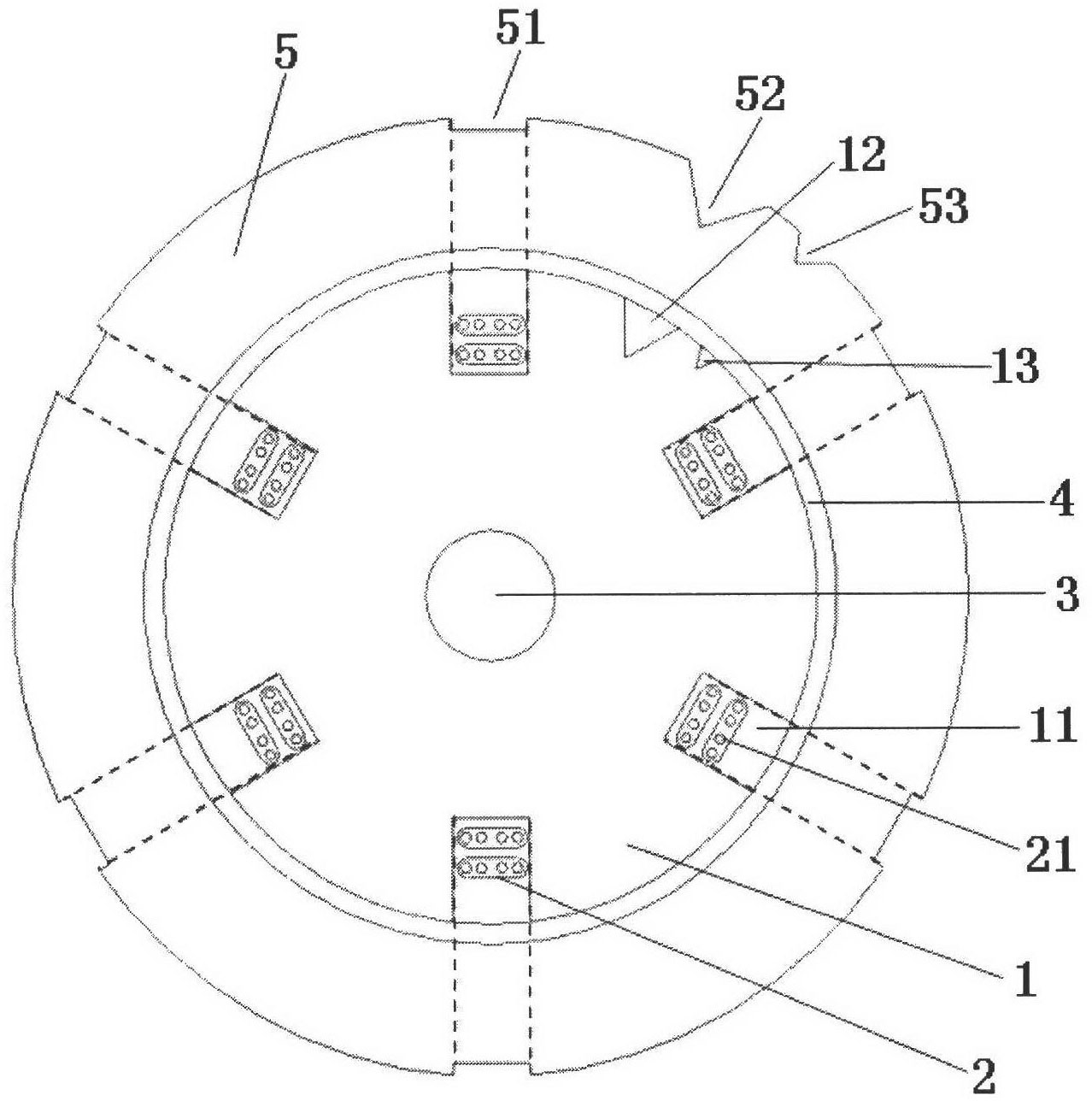

[0027] please see Figure 1 to Figure 2 , a skeleton type cable, which includes a skeleton 1, a reinforcing member 3 located in the center of the skeleton, a plurality of inner skeleton grooves 11 located on the outer circumference of the skeleton and separated from each other, a cable core 2 located in the inner skeleton groove, The protective layer 4 coated on the skeleton and the sheath 5 extruded on the protective layer; the inner skeleton grooves are distributed parallel to each other on the outer circumference of the skeleton and parallel to the reinforcement; it is characterized in that: the inner skeleton has adjacent and mutually The first groove 12 and the second groove 13 that are not connected; the first groove and the second groove are located between two adjacent inner skeleton grooves; An outer skeleton groove 51, the outer skeleton grooves are distributed parallel to each other and parallel to the reinforcing member, the position of the outer skeleton groove is...

Embodiment 2

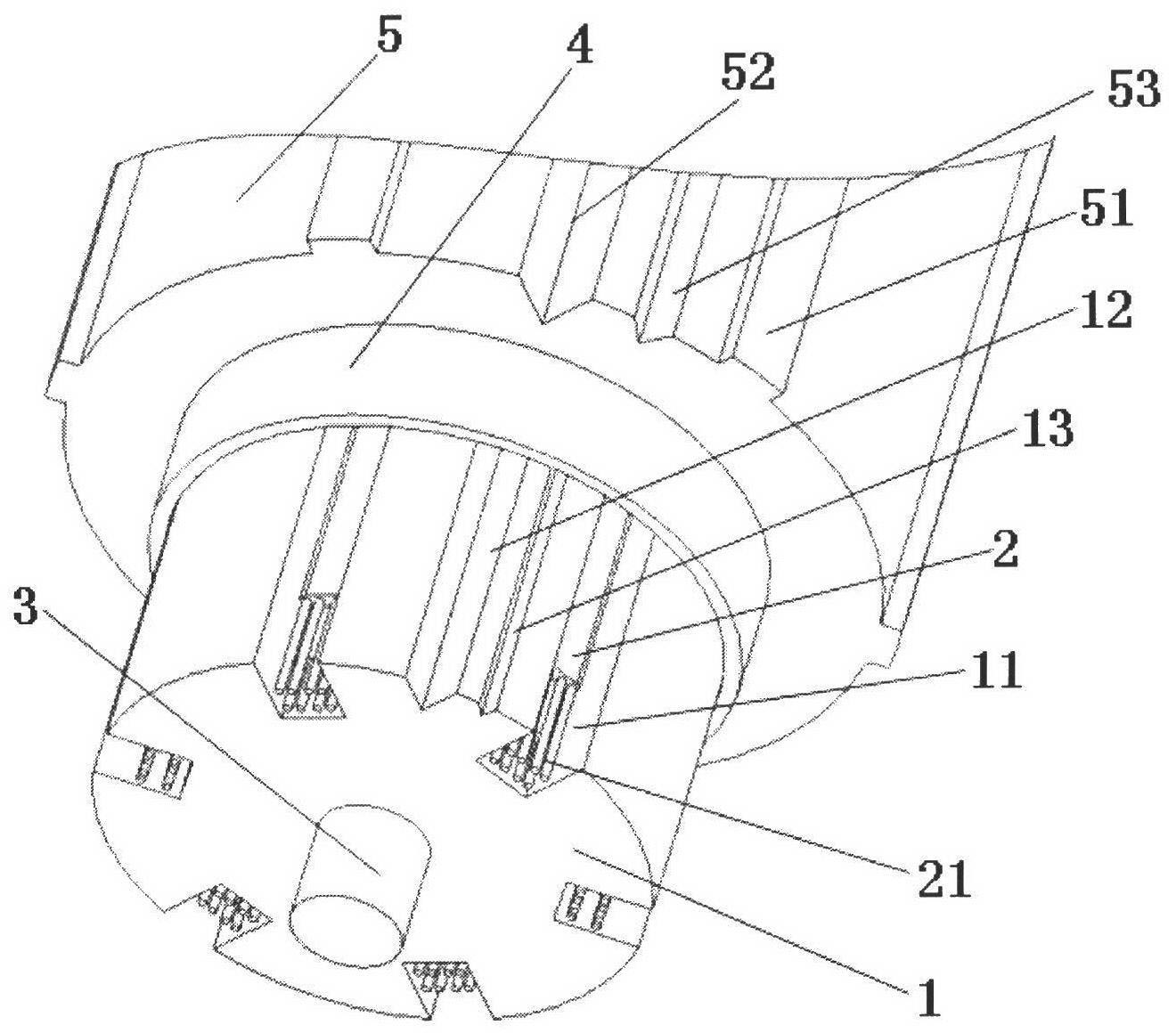

[0030] please see Figure 3 to Figure 4, a skeleton type cable, which includes a skeleton 1, a reinforcing member 3 located in the center of the skeleton, a plurality of inner skeleton grooves 11 located on the outer circumference of the skeleton and spaced apart from each other, a cable core 2 located in the inner skeleton groove, The protective layer 4 coated on the skeleton and the sheath 5 extruded on the protective layer; the inner skeleton grooves are distributed parallel to each other on the outer circumference of the skeleton and parallel to the reinforcement; it is characterized in that: the inner skeleton has adjacent and mutually The first groove 12 and the second groove 13 that are not connected; the first groove and the second groove are located between two adjacent inner skeleton grooves; there is a protrusion protruding from the outer edge of the sheath on the outer edge of the sheath A plurality of outer skeleton strips 51, the outer skeleton strips are distrib...

Embodiment 3

[0033] please see Figure 5 to Figure 8 , a skeleton type cable, which includes a skeleton 1, a reinforcing member 3 located in the center of the skeleton, a plurality of inner skeleton grooves 11 located on the outer circumference of the skeleton and spaced apart from each other, a cable core 2 located in the inner skeleton groove, The protective layer 4 coated on the skeleton and the sheath 5 extruded on the protective layer; the inner skeleton groove is distributed in a unidirectional spiral on the outer circumference of the skeleton; A plurality of depressed outer skeleton grooves 51, the outer skeleton grooves are distributed in a unidirectional spiral on the outer circumference of the sheath, and the positions of the outer skeleton grooves correspond to the positions of the inner skeleton grooves; the bottom surface of the inner skeleton grooves is a helical surface , the bottom surface of the outer skeleton groove is a helical surface and the bottom surface of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com