High-temperature, high-pressure, and acid-resisting apparatus for foam generating and dynamic evaluating

A foam generation, high temperature and high pressure technology used in measurement devices, flow characteristics, and the use of fluid flow characteristics to determine specific gravity and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

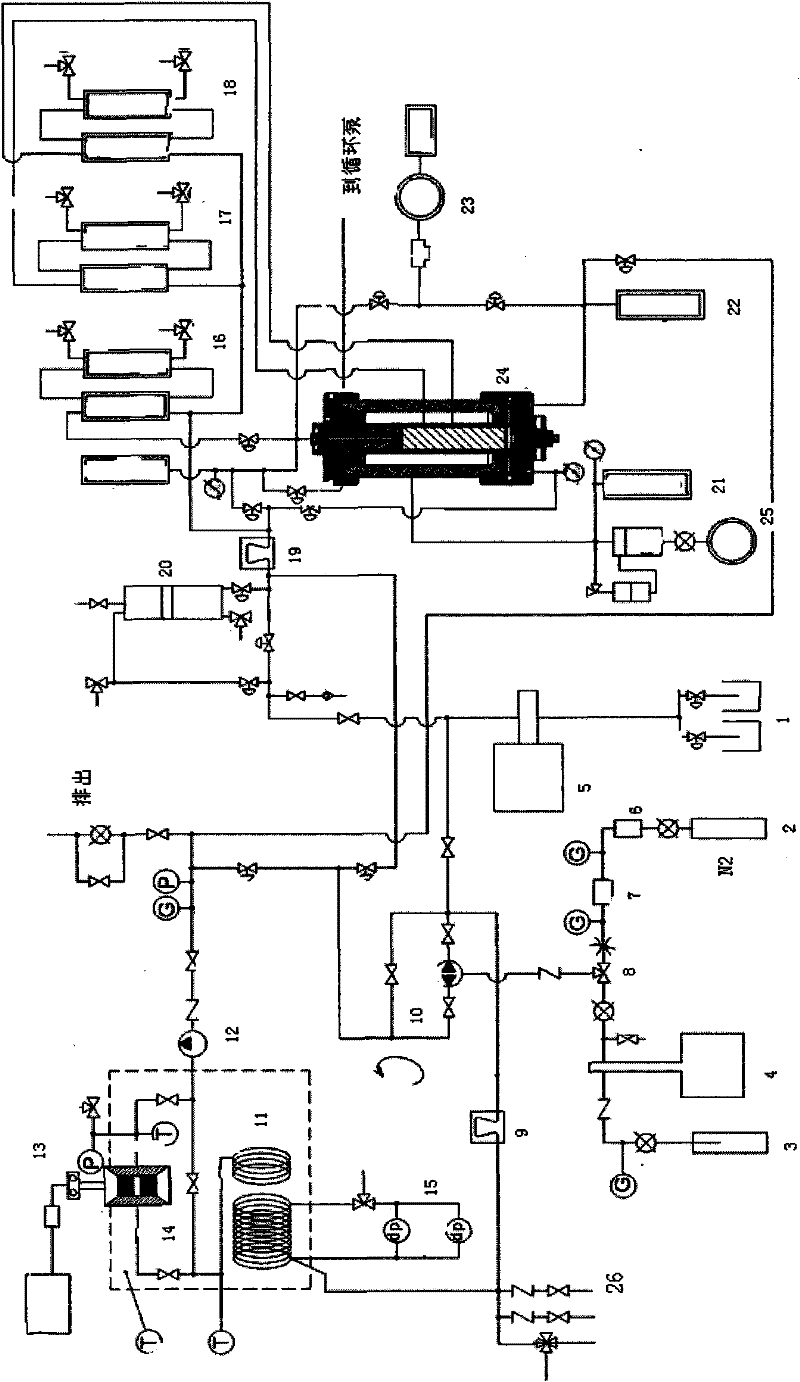

[0026] The high-temperature and high-pressure acid-resistant foam generation and dynamic evaluation device is composed of a foam generation and dynamic evaluation system, a formation damage / acidification evaluation test system, and a computer control system;

[0027] Foam generation and dynamic evaluation system includes: liquid storage tank A1 with heating jacket, high pressure positive displacement plunger pump 5, foam generator 10, nitrogen gas supply device A2 and liquid carbon dioxide gas supply device 3, gas booster pump 7, carbon dioxide high pressure Positive displacement plunger pump 4, circulation pump 12, coil heating furnace 11, data acquisition system 13, flow temperature density meter 9, differential pressure sensor A15 and cleaning system 26;

[0028] The liquid storage tank A1 with a heating jacket communicates with the foam generator 10 through a valve through a high-pressure positive displacement plunger pump 5; the nitrogen gas supply device A2 connects with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com