Fracturing Process to Enhance Propping Agent Distribution to Maximize Connectivity Between the Formation and the Wellbore

a technology of propping agent and distribution process, which is applied in the direction of borehole/well accessories, folding cabinets, cabinets, etc., can solve the problems of very rapid production decline, high cost and time consumption, and shortened production cycle, so as to maximize connectivity, improve production, and enhance the distribution of propping agen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention relates generally to enhancing propping agent distribution in order to maximize connectivity between a subterranean formation and a wellbore so as to improve production from a subterranean formation.

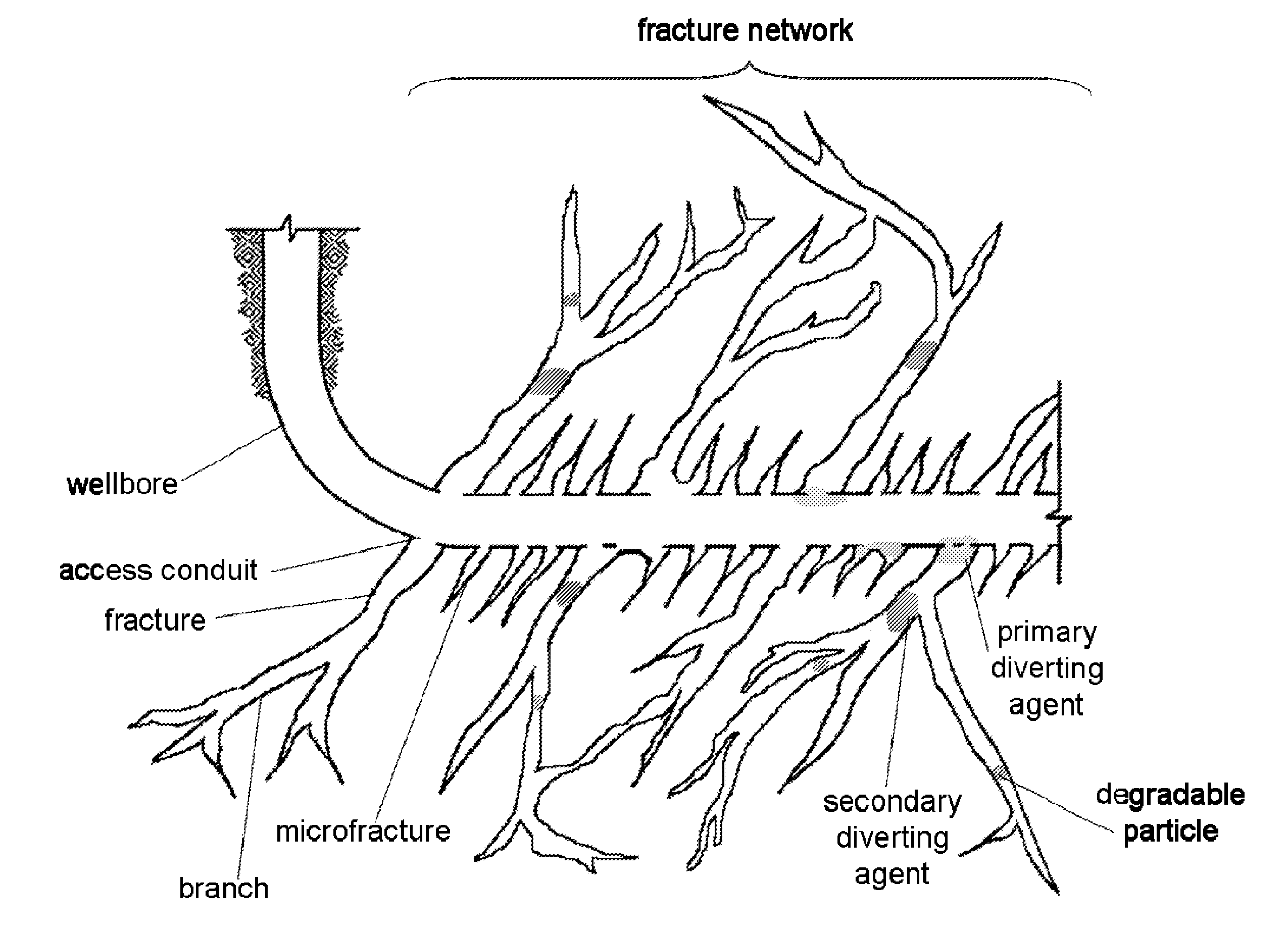

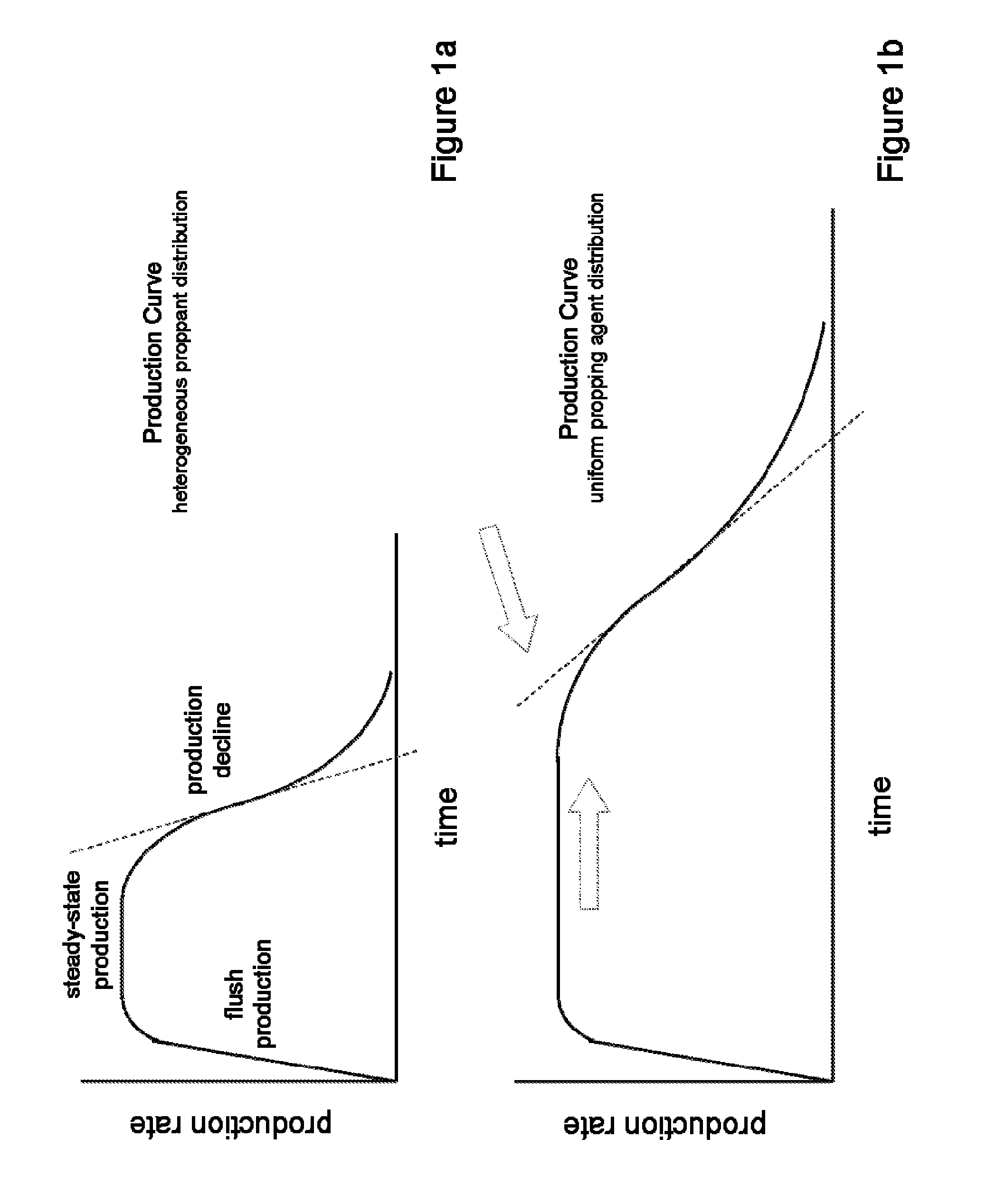

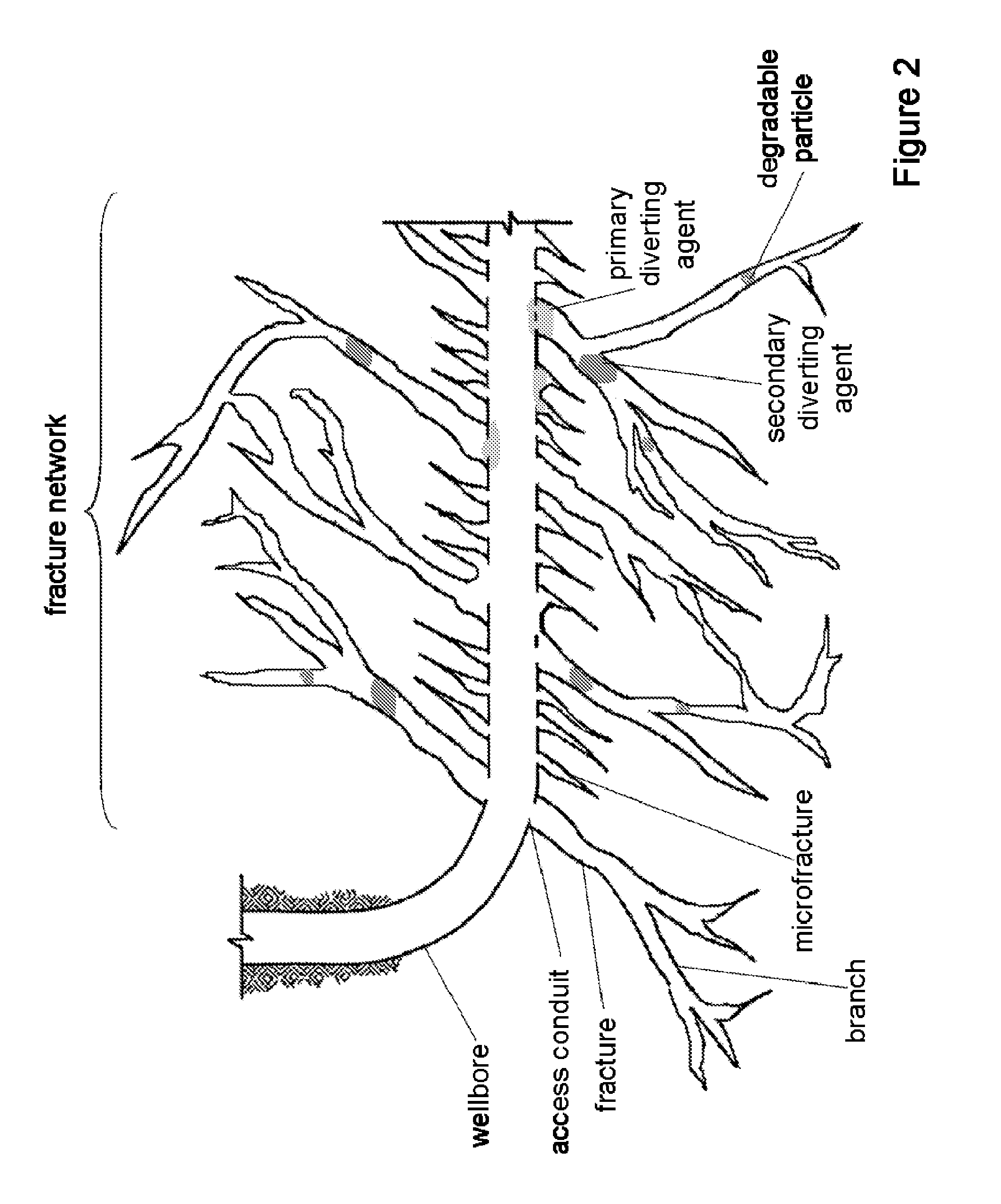

[0020]The methods of the present invention provide for the systematic introduction of a series of diverting agents that enhances the uniform distribution of propping agents through a fracture network. In brittle formations, like shale, a fracture network may comprise access conduits, fractures, microfractures, and branches. As used herein, an “access conduit” refers to a passageway that provides fluid communication between the wellbore and the subterranean formation, which may include, but not be limited to, sliding sleeves, open holes in non-cased areas, hydrajetted holes, holes in the casing, perforations, and the like. The methods of the present invention provide for treatment fluid and propping agent diversion in at least each of these fracture network com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com