Patents

Literature

31results about How to "Less harmful to the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shale oil and gas fracturing fluids containing additives of low environmental impact

InactiveUS20140090850A1Less harmfulLess harmful to the environmentFluid removalFlushingParticulatesFracturing fluid

The present invention relates to improved chemical additives for use in hydraulic fracturing fluids for the recovery of oil or natural gas entrained in deep-layer shale formations. Many chemical agents currently in use in such water / sand (or other proppants) mixtures could pose human and animal health risks if these chemicals migrate from the shale beds into the environment contaminating the water table, rivers, streams and lakes. The fracturing fluid chemical additives of this invention are designed to be retained or anchored in or near the deep shale layers and are prevented, or greatly delayed from upward migration. Specifically, many chemical additives required for proper fracturing fluid performance can be chemically bonded to inert particulate materials before incorporation into said fluids. The fracturing fluid chemical additives are able to perform their function in the shale fracturing process, and then become nearly permanently trapped in the shale layers protecting the environment above.

Owner:BATTELION ENERGY

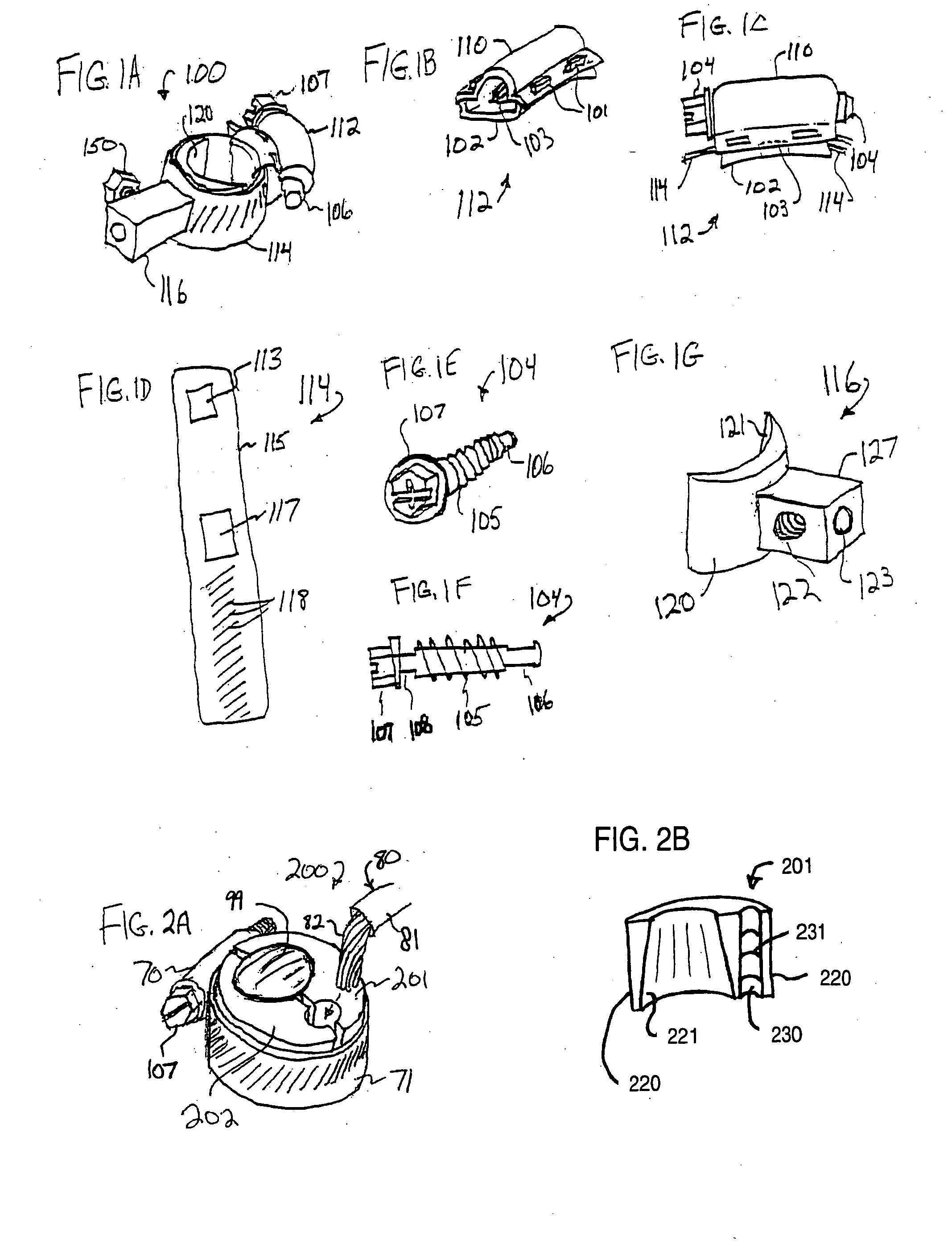

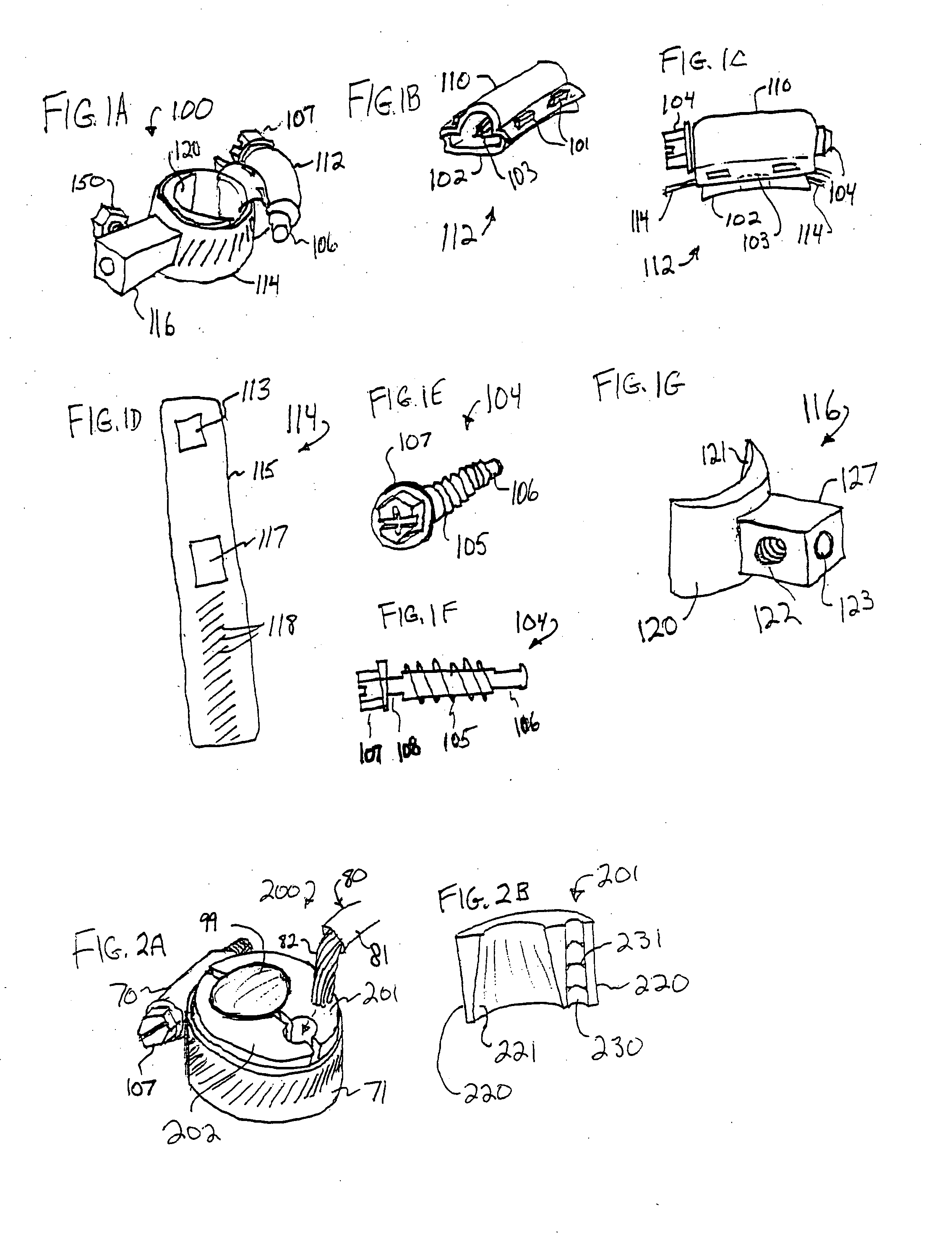

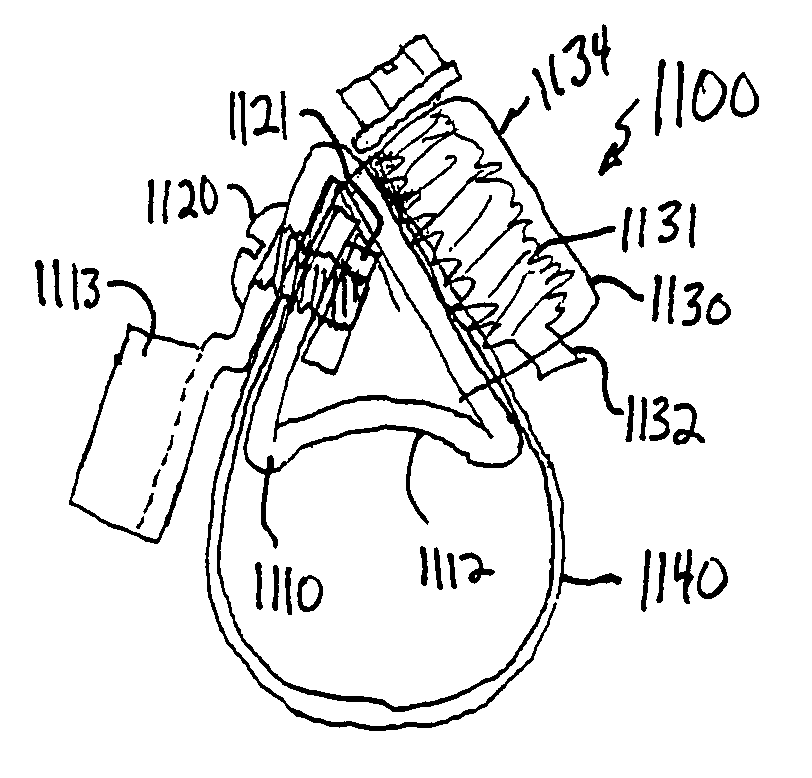

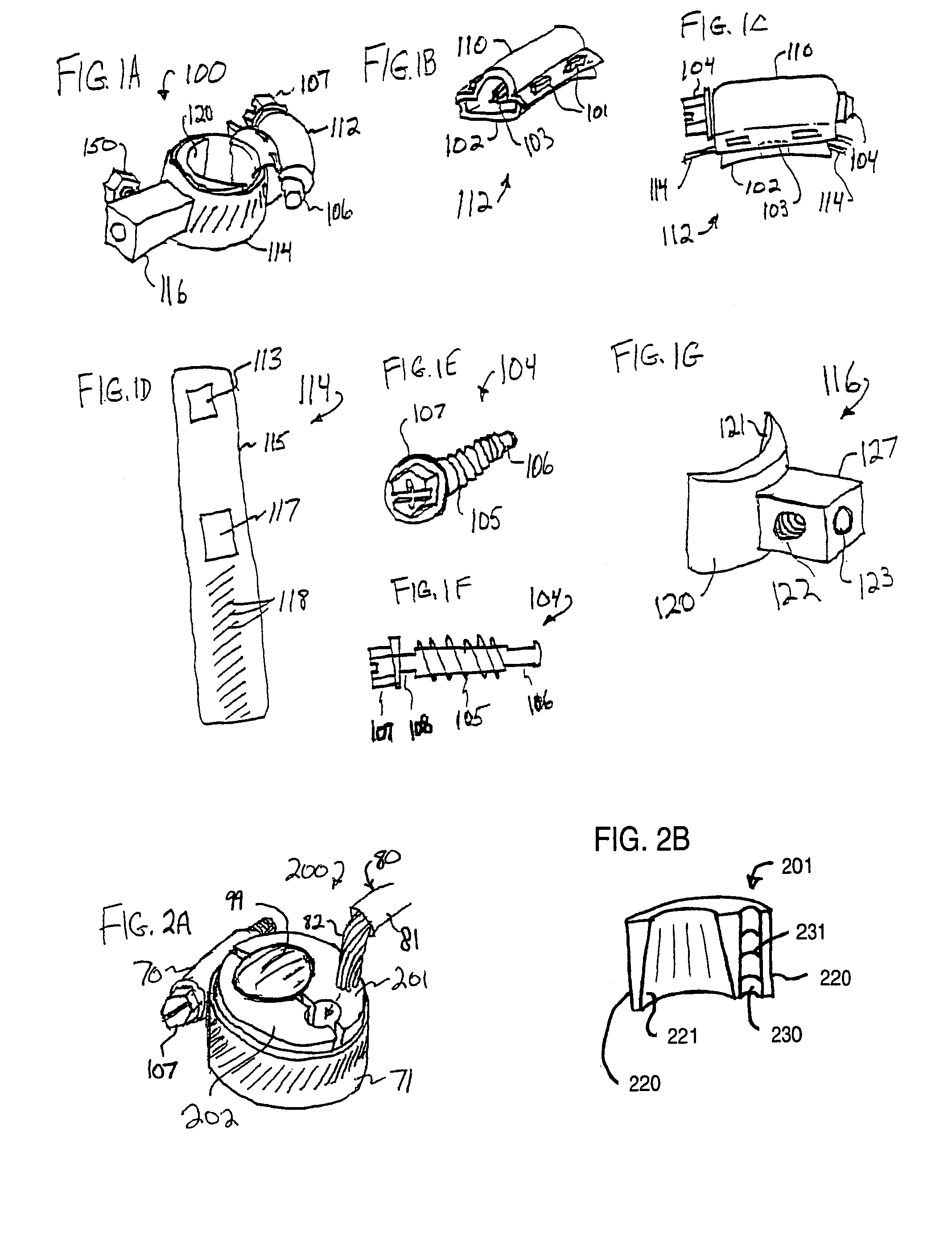

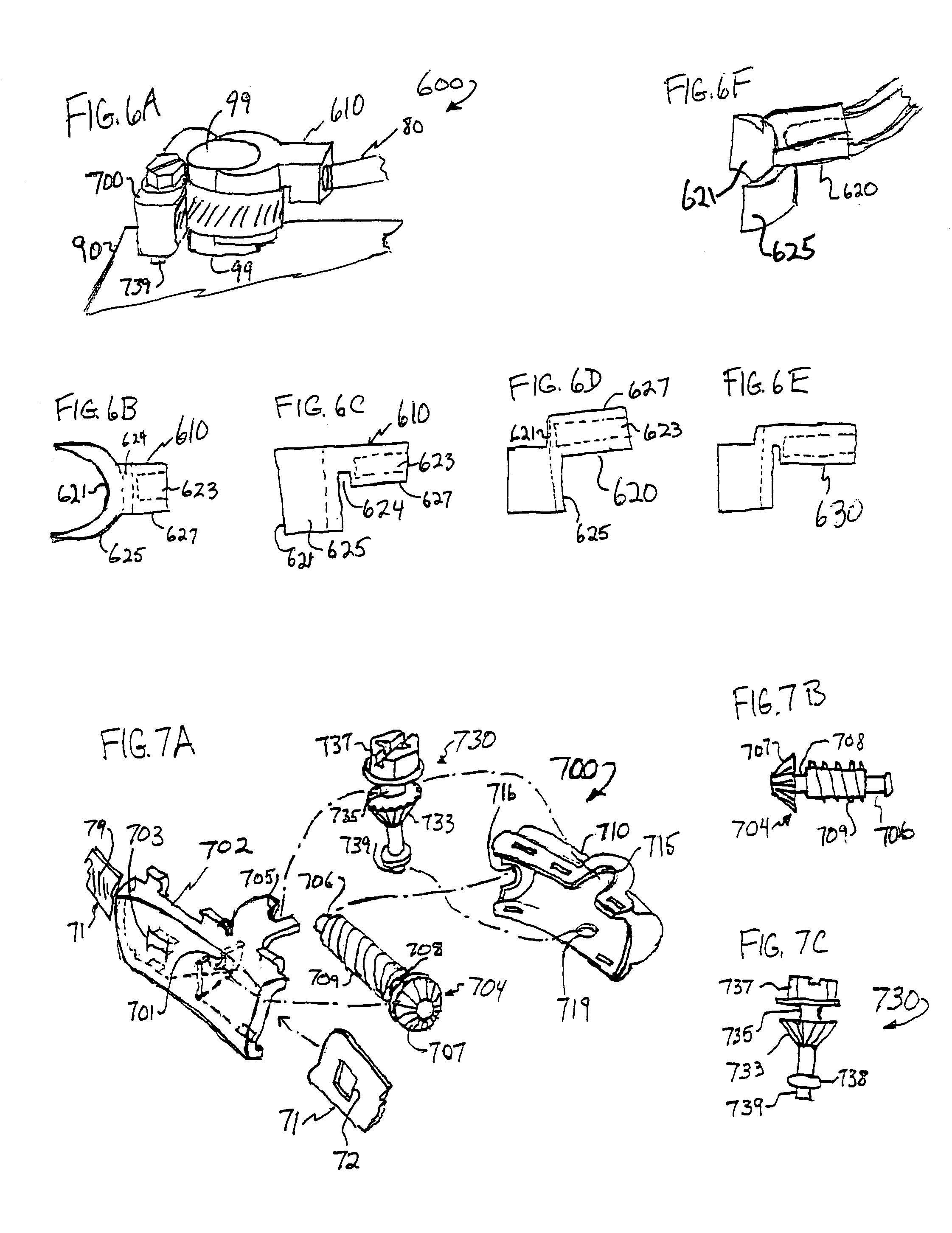

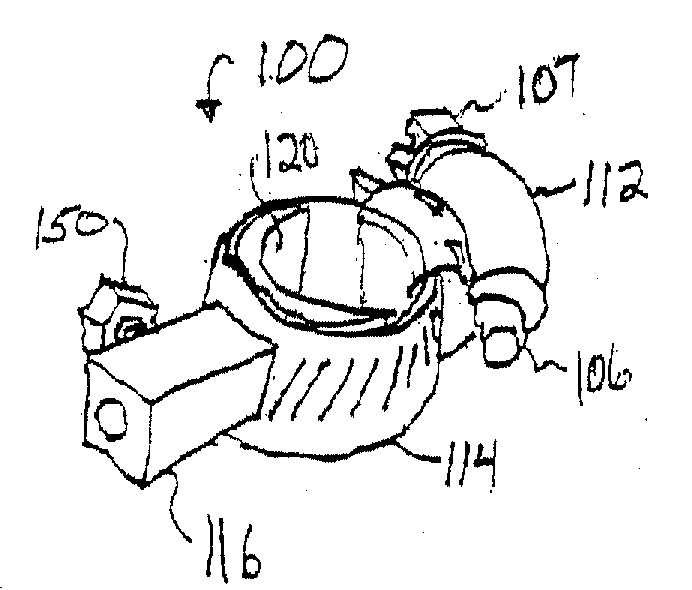

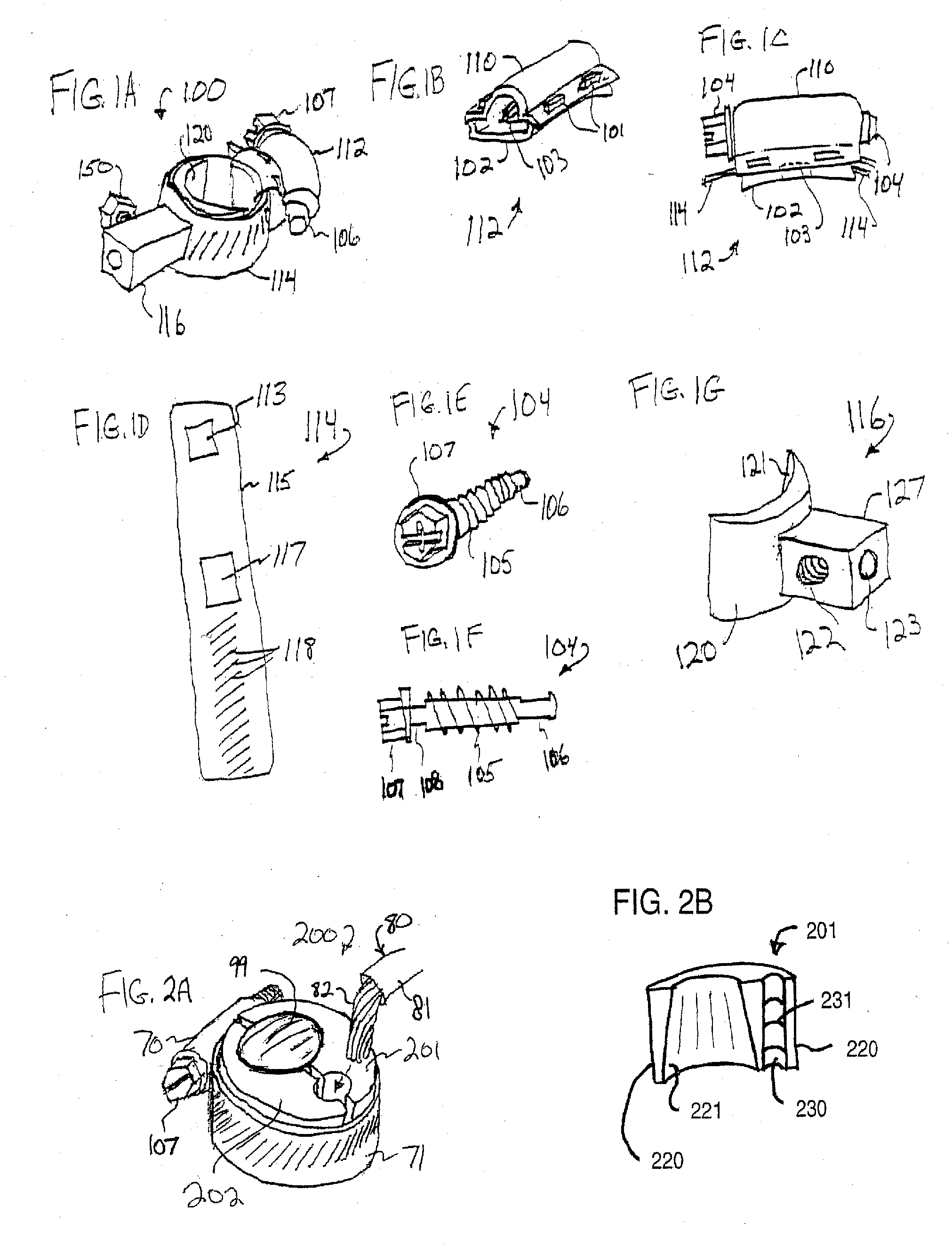

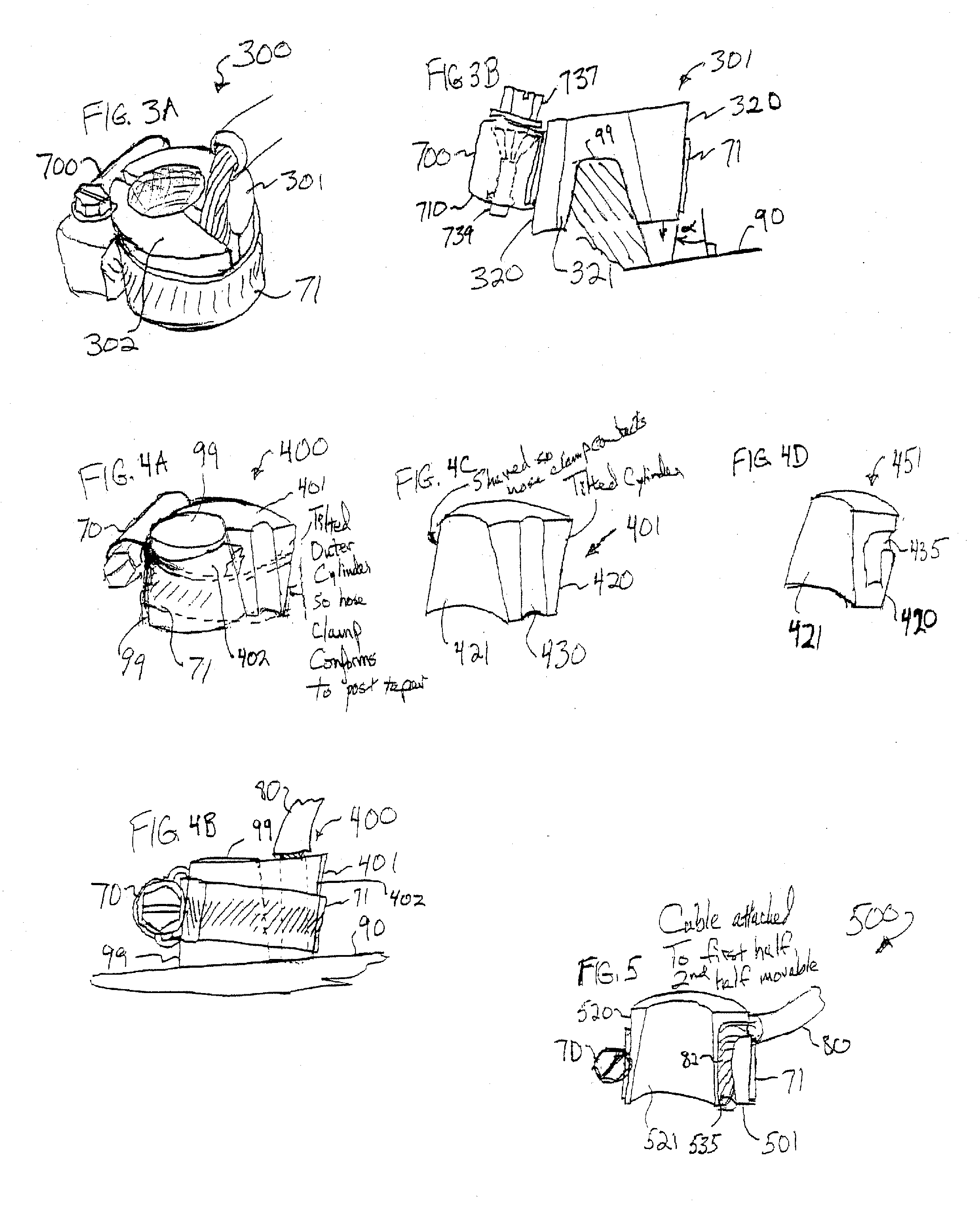

Symmetrically adjustable corrosion-resistant battery cable connector

InactiveUS20050106952A1Easy to installEasy to removeSnap fastenersClothes buttonsElectricityElectrical conductor

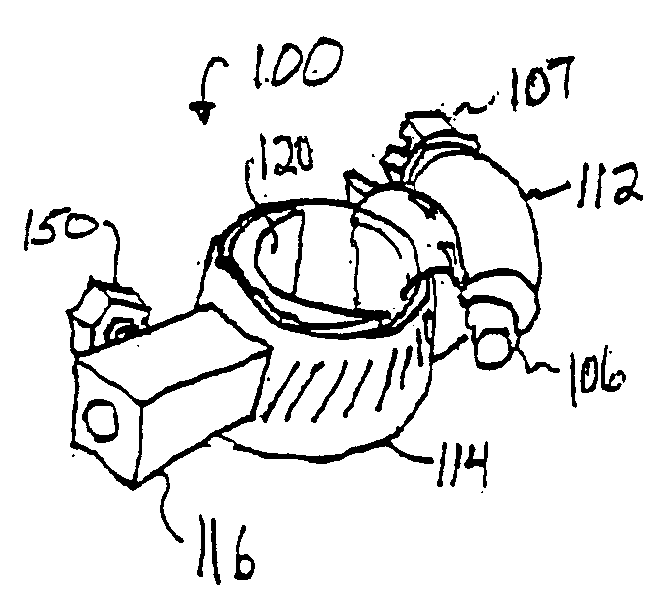

An electromechanical connector for use between a power source such as a battery and a device requiring the power such as an automotive electrical system. In some embodiments, the connector includes a radius electrical contact constituting a primary electrical current path, and a band clamp with a slotted band constituting a secondary current path, and a worm drive adjustment assembly for symmetrically tighten the connector to the battery post. A kit is described having an electrical-contact conductor with a concave surface conforming to a battery post, and a band clamp to symmetrically compress the conductor against the post. Some embodiments provide a conductor that conforms to an outer portion of the post, and includes a band clamp mechanism with a band fixed at a non-moving end to the conductor, and at an opposite slotted end interfacing to a worm screw held against the conductor.

Owner:MECHANICAL ANSWERS

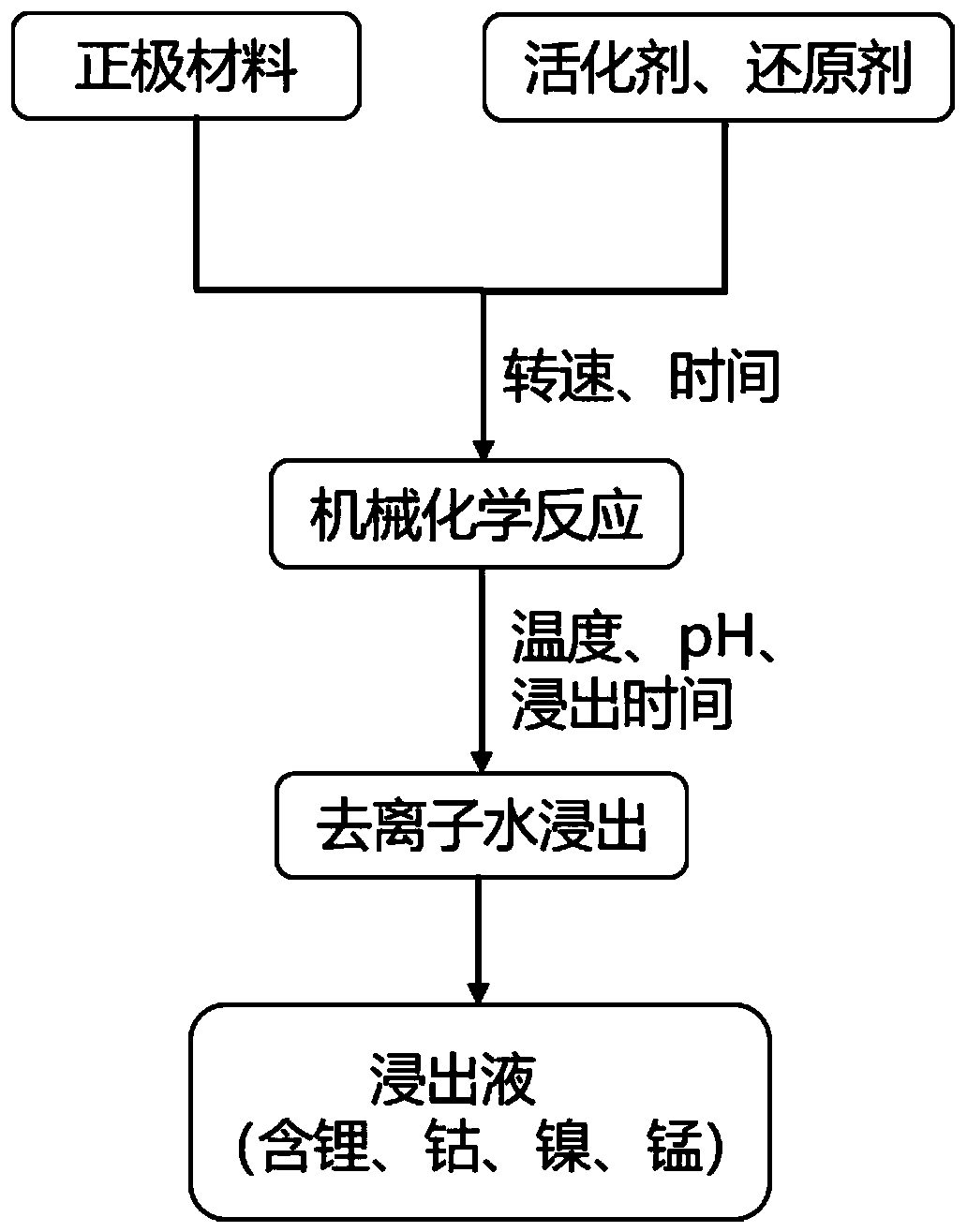

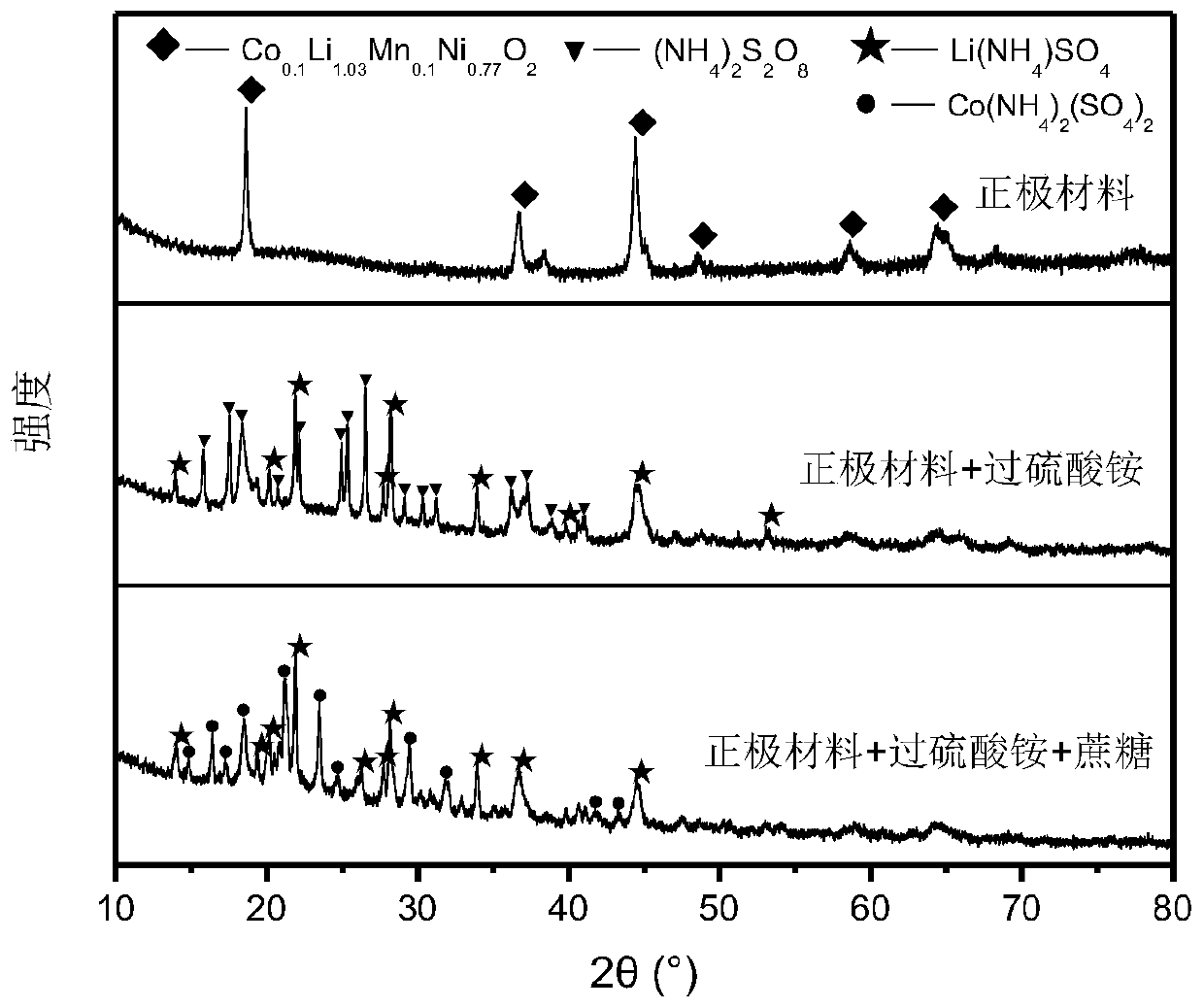

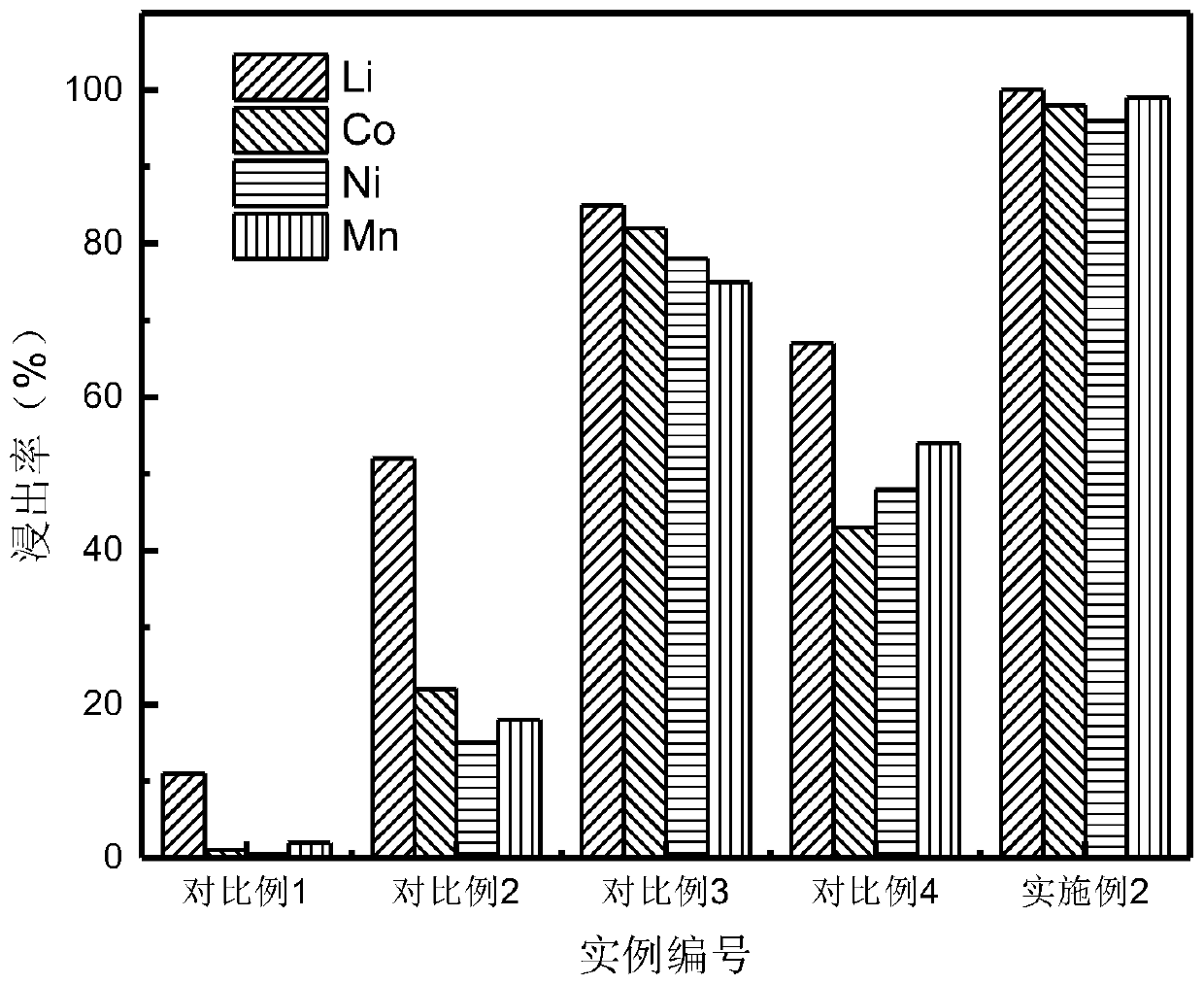

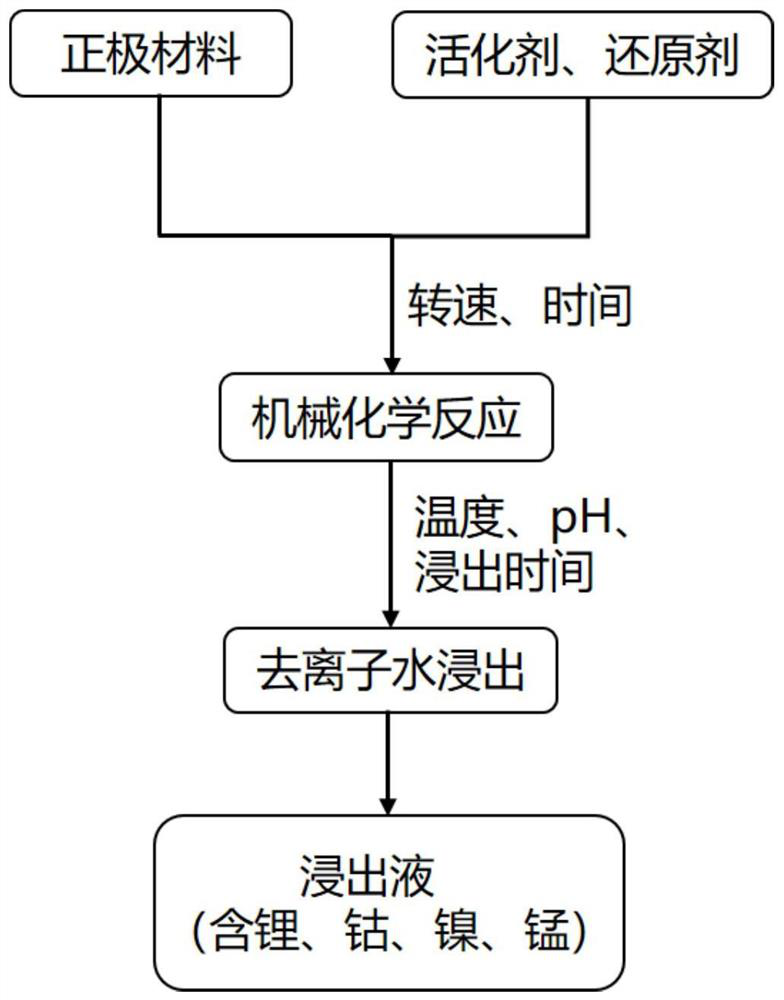

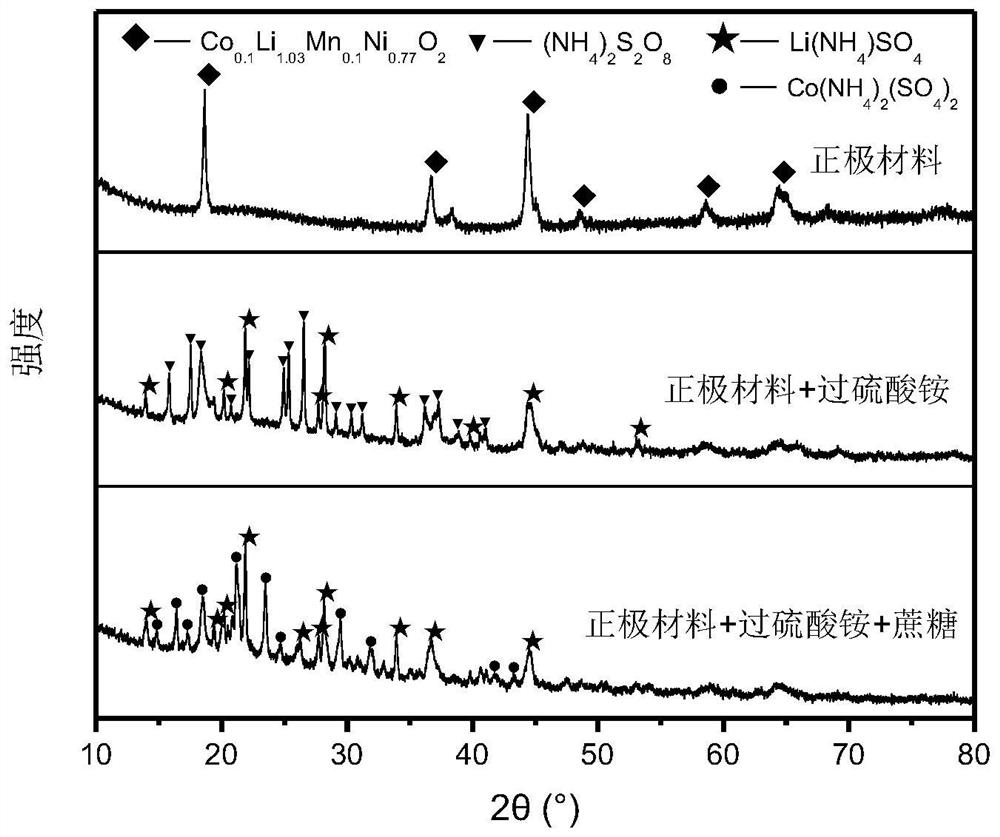

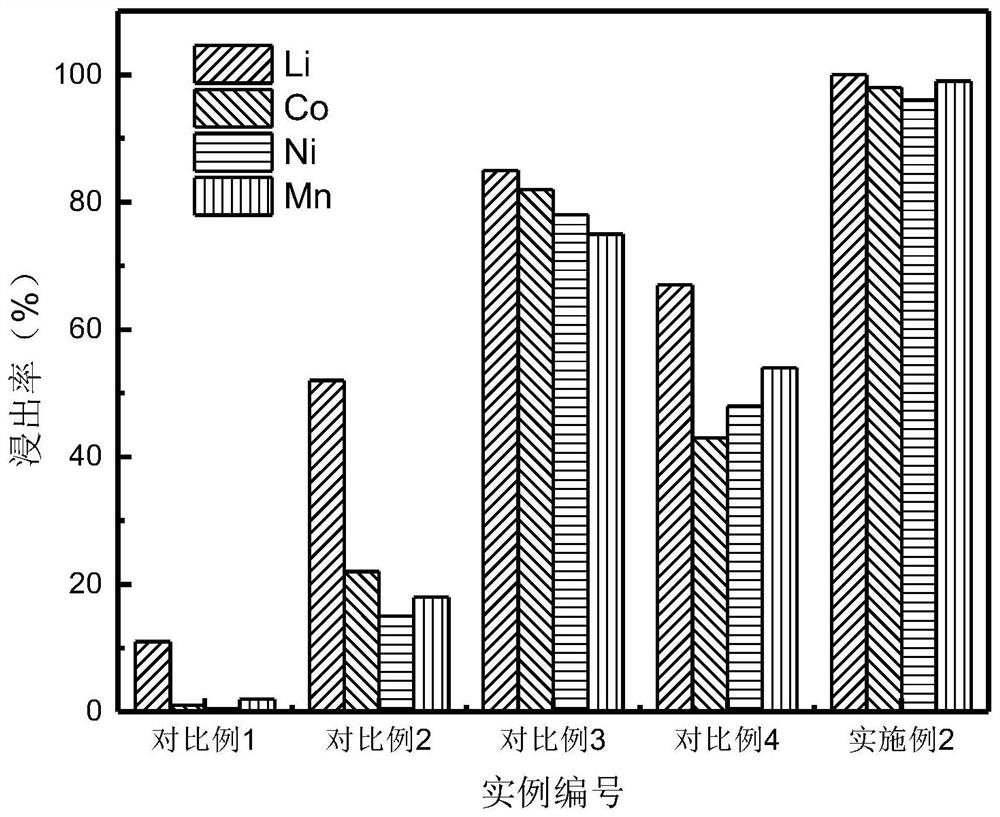

Recovery method for waste lithium ion battery anode materials based on mechano-chemical method

ActiveCN110791652AEfficient leachingHazard reductionWaste accumulators reclaimingProcess efficiency improvementMetallic lithiumChemical reaction

The invention discloses a recovery method for waste lithium ion battery anode materials based on a mechano-chemical method, and belongs to the field of waste lithium ion battery recycling. The waste lithium ion battery anode materials are ground into powder, the powder is sufficiently and evenly mixed with an activating agent and an organic reducing agent, the activating agent can generate activefree radicals, a mixture is obtained, the mixture is subjected to ball grinding, the waste lithium ion battery anode materials generate plastic deformation, lattice imperfection is generated in crystal particles, and the crystal particles generate crystal transfer or are not crystallized; and products obtained after ball grinding are added into deionized water, and valuable metal ions are leached.The method does not depend on high-concentration strong acid, strong base, strong oxidization reducing reagents, expensive organic acid and the like, the mechano-chemical reaction in a solid phase isadopted as a reaction body, and efficient leaching of valuable metal lithium, cobalt, nickel, manganese and the like in the waste lithium ion battery anode materials is achieved under the mild leaching environment.

Owner:HUAZHONG UNIV OF SCI & TECH

Symmetrically adjustable corrosion-resistant battery cable connector

InactiveUS7052331B2Easy to installEasy to removeSnap fastenersClothes buttonsElectricityElectrical conductor

An electromechanical connector for use between a power source such as a battery and a device requiring the power such as an automotive electrical system. In some embodiments, the connector includes a radius electrical contact constituting a primary electrical current path, and a band clamp with a slotted band constituting a secondary current path, and a worm drive adjustment assembly for symmetrically tighten the connector to the battery post. A kit is described having an electrical-contact conductor with a concave surface conforming to a battery post, and a band clamp to symmetrically compress the conductor against the post. Some embodiments provide a conductor that conforms to an outer portion of the post, and includes a band clamp mechanism with a band fixed at a non-moving end to the conductor, and at an opposite slotted end interfacing to a worm screw held against the conductor.

Owner:MECHANICAL ANSWERS

Polymer catalytic membrane containing palladium metal activity functional layer and preparation method thereof

InactiveCN102512991AEasy to prepareNo need for external power conditionsSemi-permeable membranesOrganic compound preparationPotassium borohydridePolyethylene glycol

The invention relates to a polymer catalytic membrane containing a palladium metal activity functional layer prepared based on the technology of layer-by-layer self assembly and a preparation method thereof, which belongs to the field of catalytic membranes. According to the invention, polyacrylonitrile (PAN) powder, polyethylene glycol (PEG) and polyvinylpyrrolidone (PVP) are dissolved in N,N-dimethyl formamide (DMF), and a PAN flat base membrane is prepared by using a phase inversion process; then the PAN membrane is soaked in a NaOH solution for treatment, which allows surface of the membrane to hydrolyze so as to produce carboxyl groups, thereby enabling the surface of the membrane to carry negative electric charges; a polyethyleneimine (PEI) solution and a potassium chloropalladate K2PdCl4 solution are fully mixed and react for a certain period of time so as to obtain a coordination compound of polyethyleneimine-palladium (PEI-Pd(II)); the treated flat base membrane is alternatively soaked in a solution containing the PEI-Pd(II) coordination compound and a polystyrene sulfonate (PSS) solution for self-assembly of functional layers on the surface of the membrane, and the amount of the assembled layers is controlled; and finally, the membrane obtained after assembly is soaked in a potassium borohydride KBH4 solution, Pd(II) is reduced to be Pd0, and the PAN catalytic membrane containing the palladium metal particle active layer is prepared.

Owner:TIANJIN POLYTECHNIC UNIV

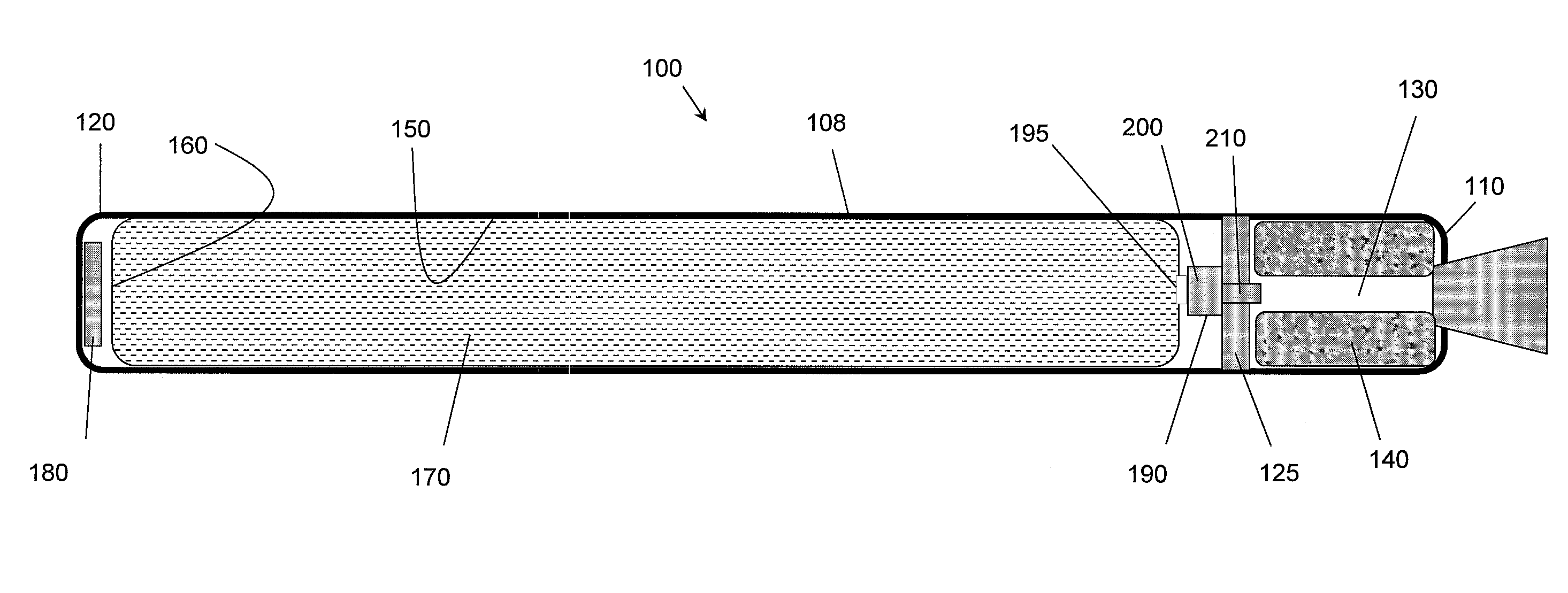

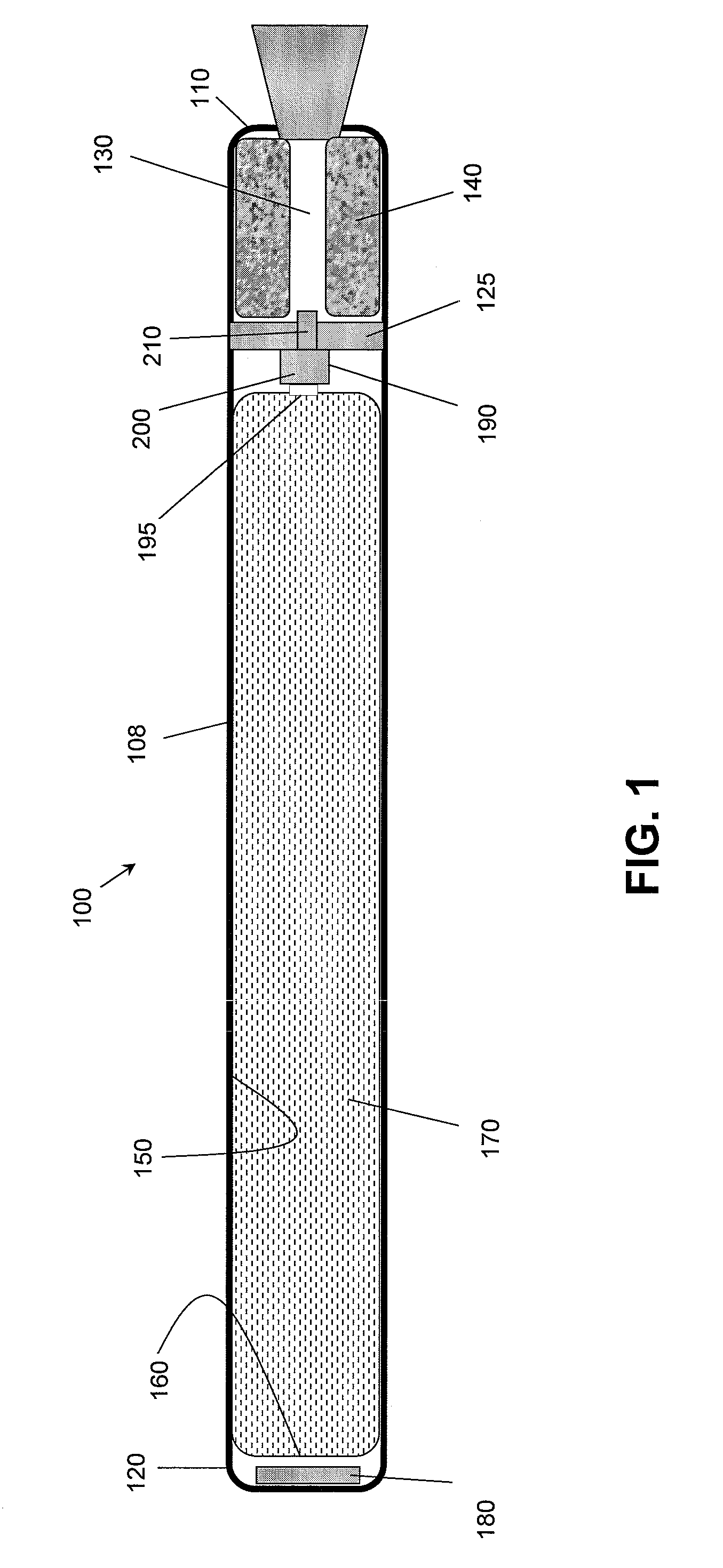

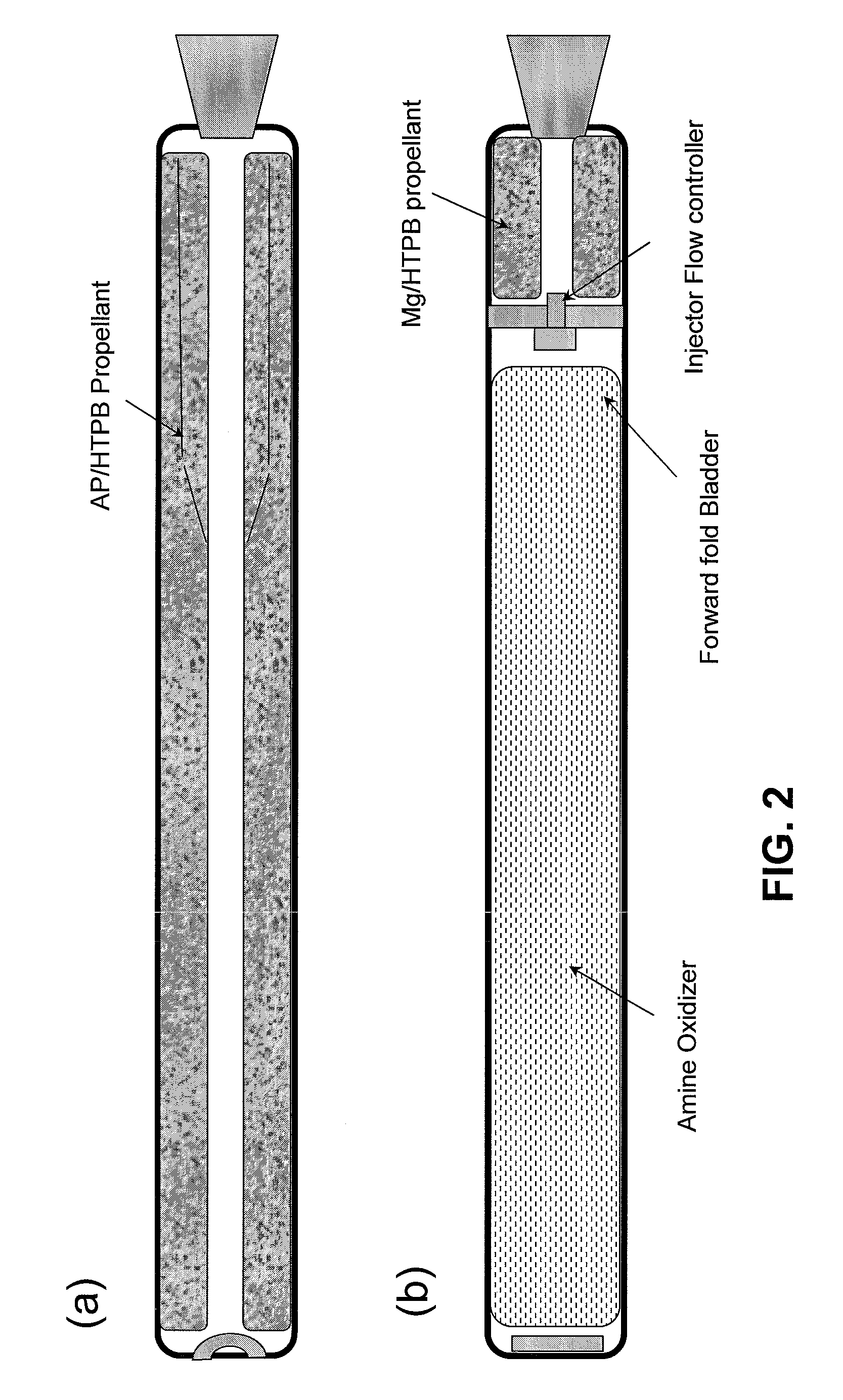

Hydroxyl Amine Based Staged Combustion Hybrid Rocket Motor

ActiveUS20090211227A1Reduce rateGood flexibilityRocket engine plantsPressure gas generationCombustion chamberSolid fuel

A new rocket motor assembly configuration is disclosed. Amine based oxidizer is decomposed in the presence of a metallic catalyst to generate an oxygen rich hot gas stream. The hot gas stream is used to trigger a Magnesium based solid fuel in the combustion chamber. The thrust of the rocket motor may be regulated at multiple points. This design thus offers an IM compliant, thrust-adjustable rocket motor that is of a low hazard classification without compromising its performance.

Owner:RAYTHEON CO

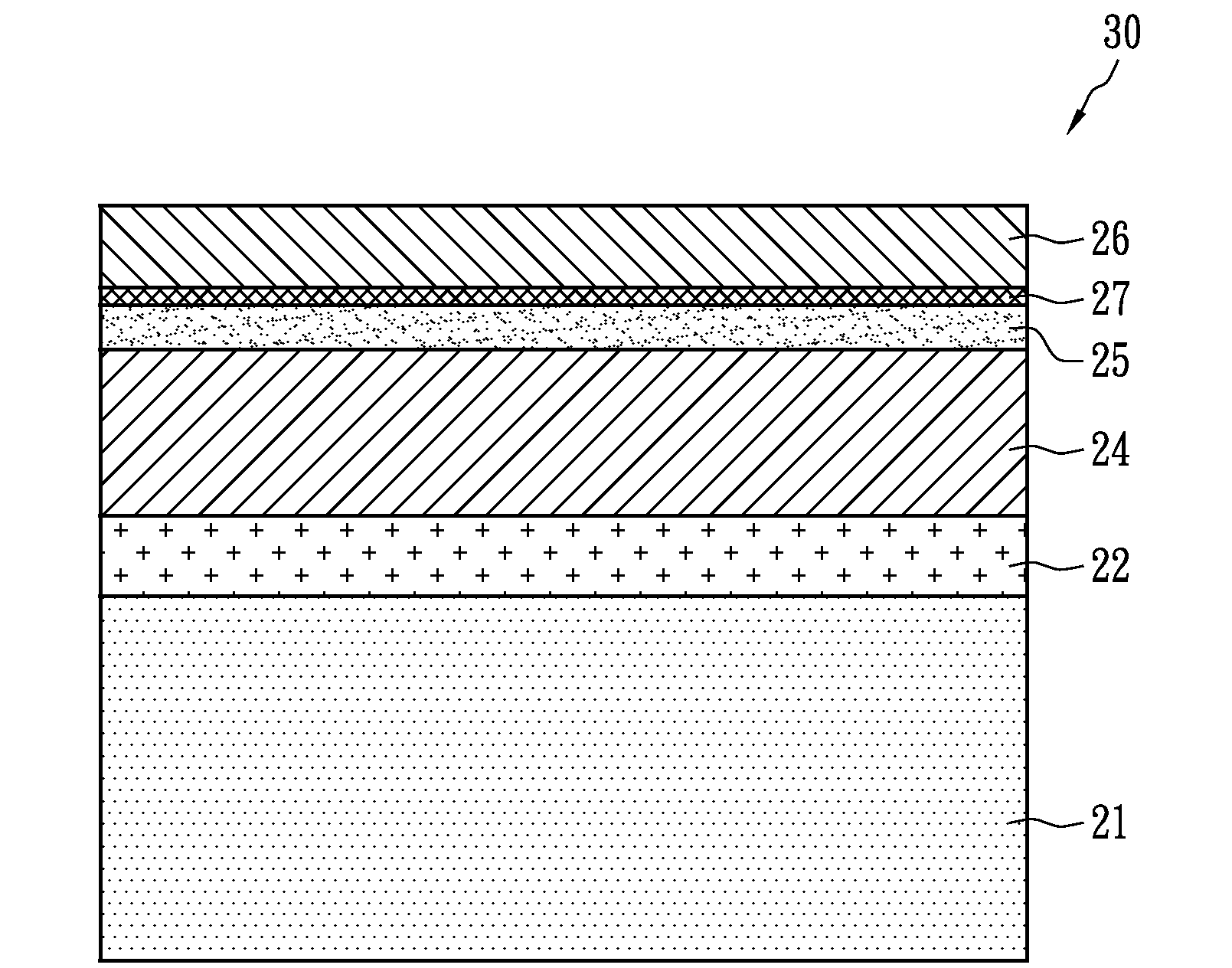

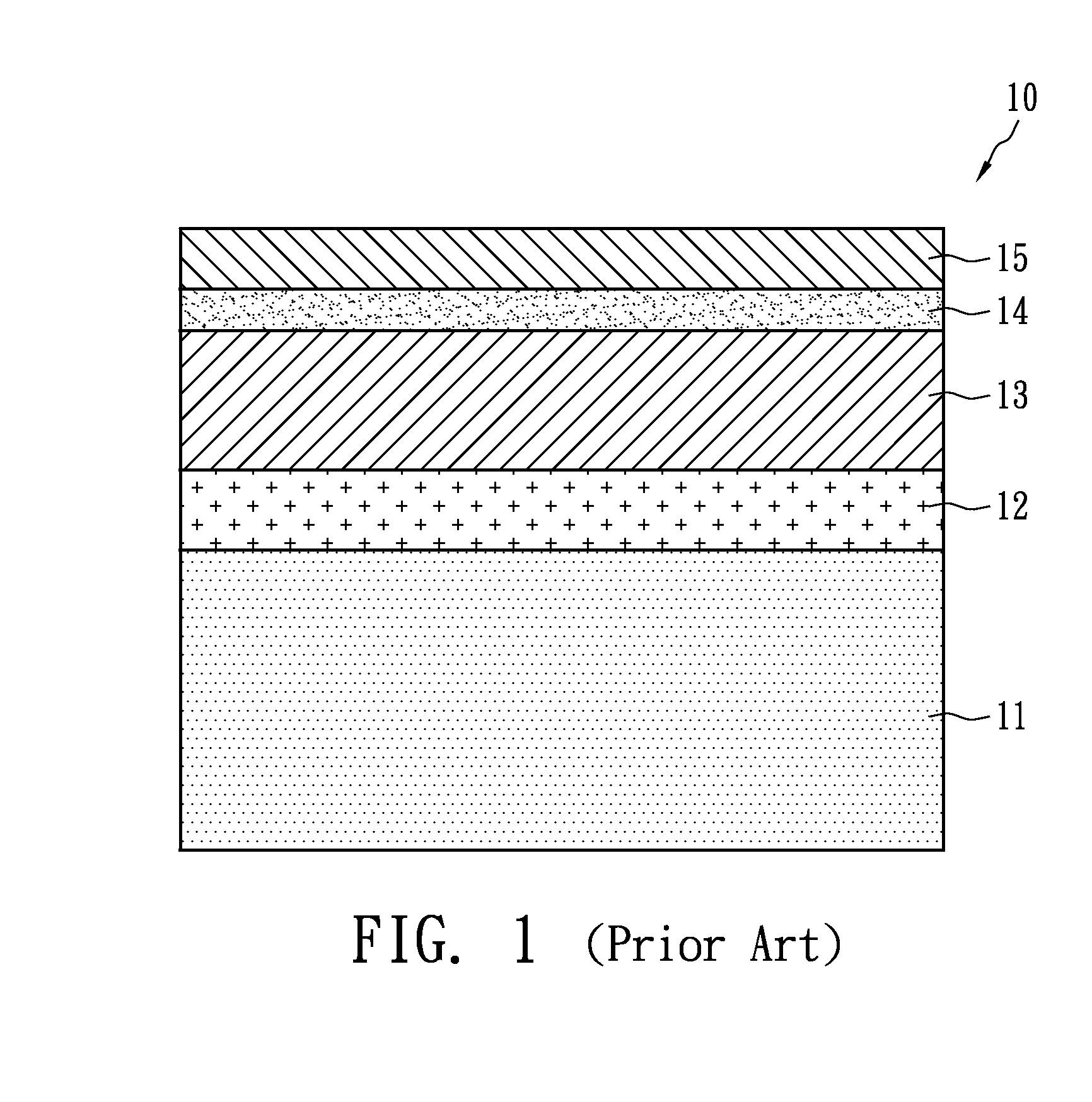

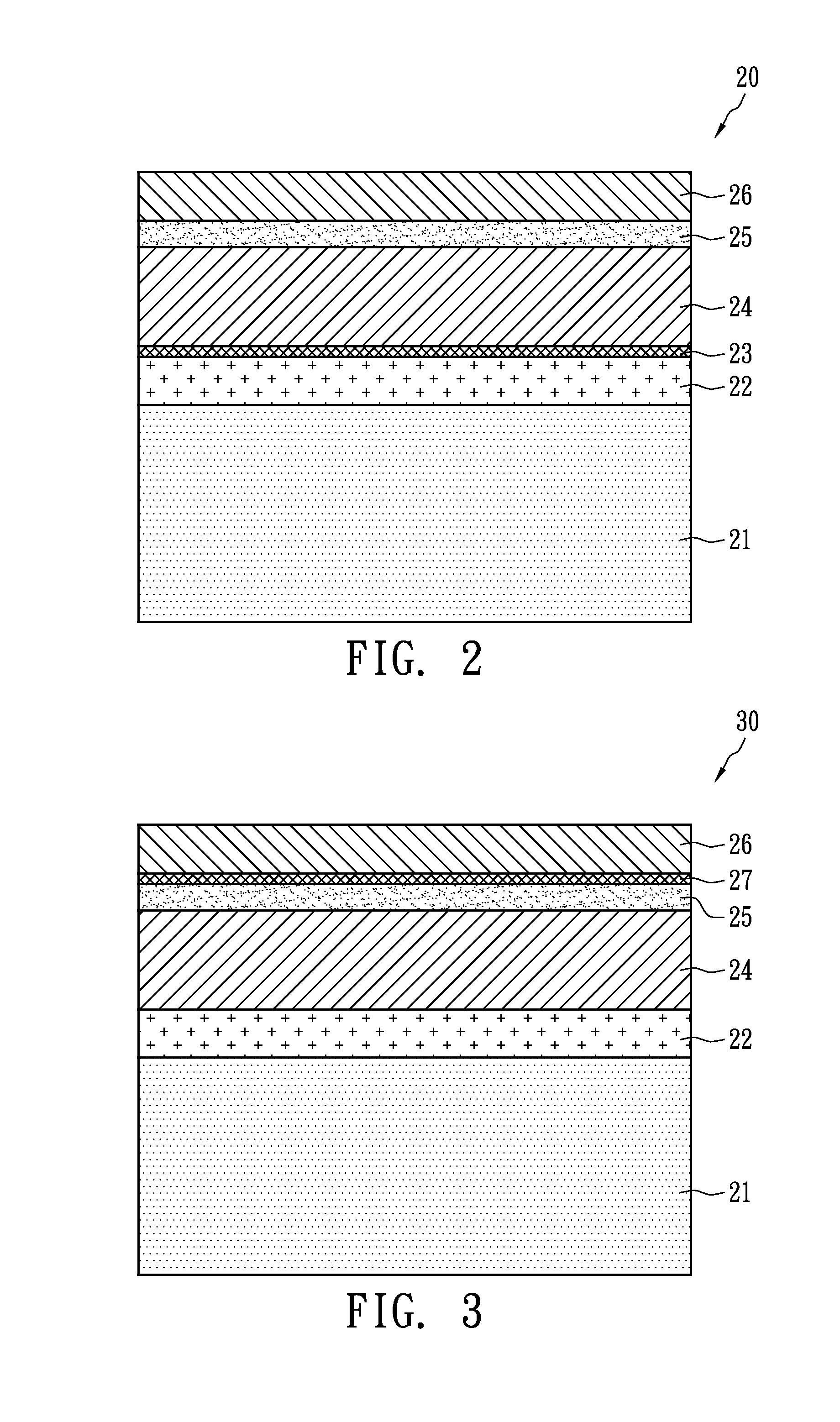

Photovoltaic cell structure

InactiveUS20100243044A1Much of contaminationMuch of wasteFinal product manufacturePhotovoltaic energy generationIndiumCopper indium gallium selenide solar cells

A photovoltaic cell structure includes a substrate, a metal layer, a p-type semiconductor layer, an n-type semiconductor layer, a transparent conductive layer and a high resistivity layer. The metal layer is formed on the substrate. The p-type semiconductor layer is formed on the metal layer and may include a compound of copper indium gallium selenium sulfur (CIGSS), copper indium gallium selenium (CIGS), copper indium sulfur (CIS), copper indium selenium (CIS) or a compound of at least two of copper, selenium or sulfur. The n-type semiconductor layer exhibits photo catalyst behavior that can increase carrier mobility by receiving light, and is formed on the p-type semiconductor layer, thereby forming a p-n junction. The transparent conductive layer is formed on the n-type semiconductor layer. The high resistivity layer is formed between the metal layer and the transparent conductive layer.

Owner:PVNEXT CORP

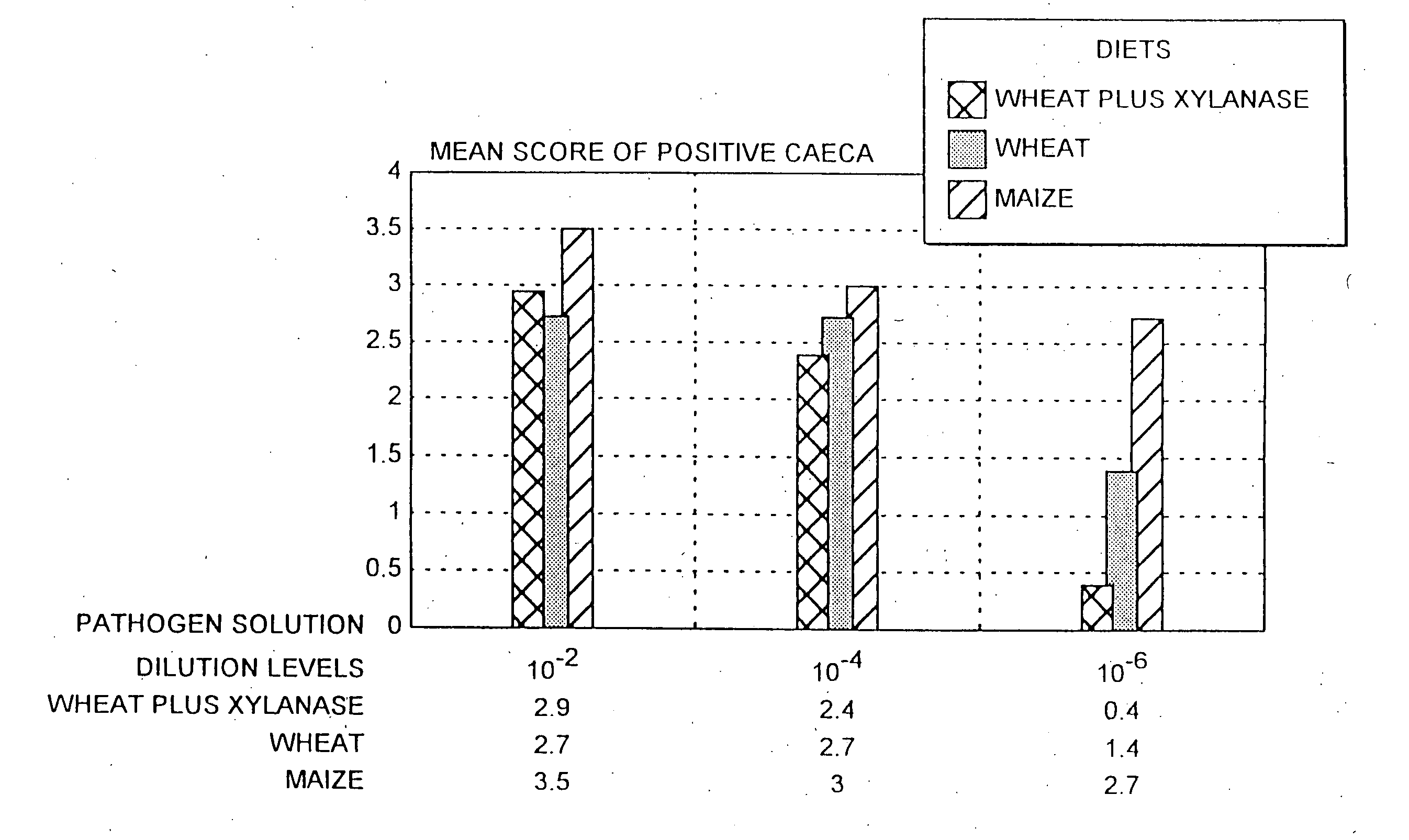

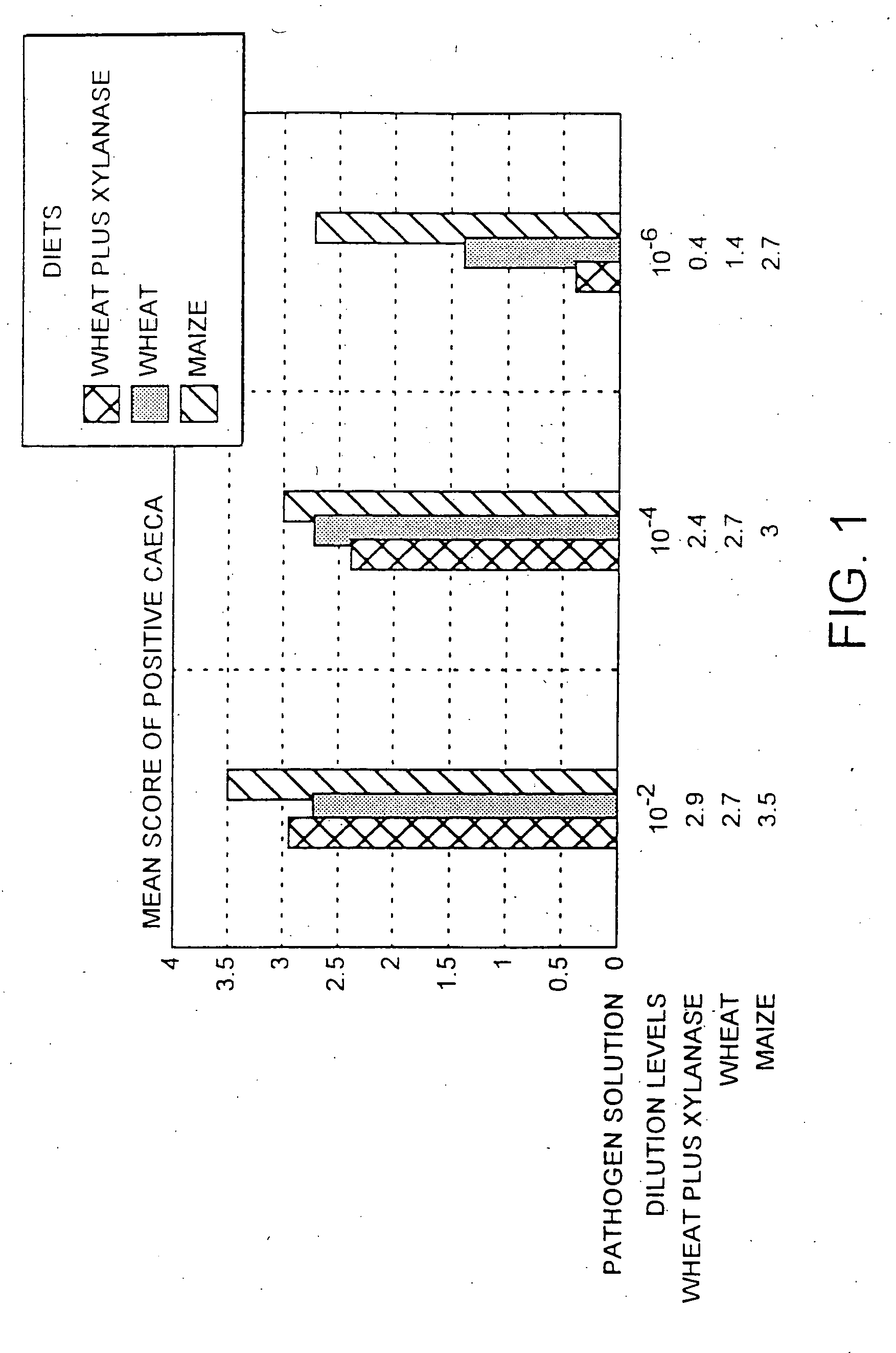

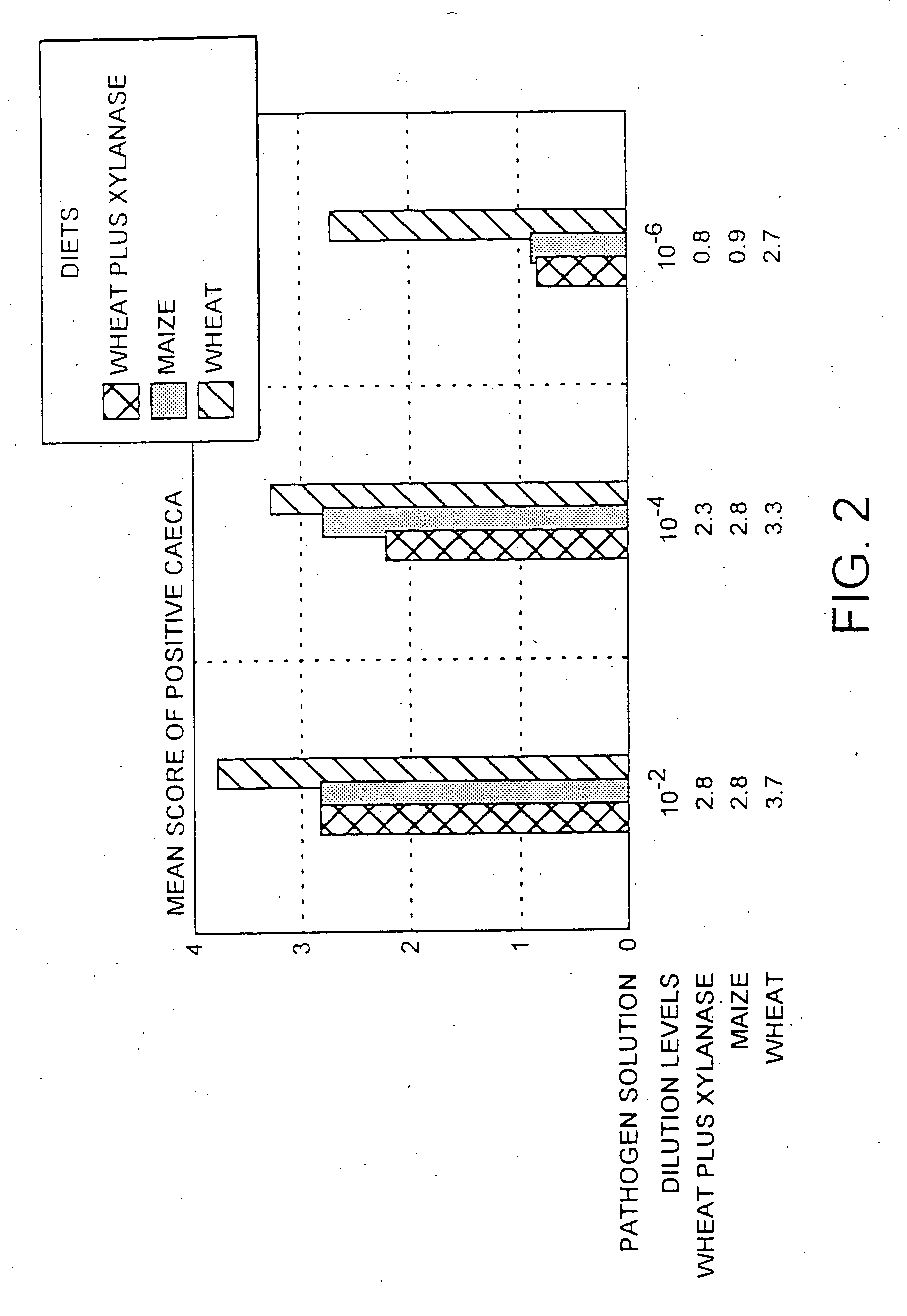

Use of an enzyme for the manufacture of an agent for controlling bacterial infection

InactiveUS20060083731A1Advantage for human healthLess harmful to the environmentAntibacterial agentsBiocideBacillus perfringensEconomic benefits

Xylanase or a cellulase for the manufacture of an agent for the treatment and / or prophylaxis of bacterial infection in an animal caused by Salmonella, Campylobacter or Clostridium perfringens. It is preferred that xylanase is used in combination with wheat to form an animal feed. Such a diet is particularly effective in controlling Campylobacter and Salmonella in chickens. The use provided by the present invention affords an alternative to antibiotics when controlling bacterial infection in animals. This leads to considerable health, environmental and economic benefits.

Owner:FINNFEEDS INT

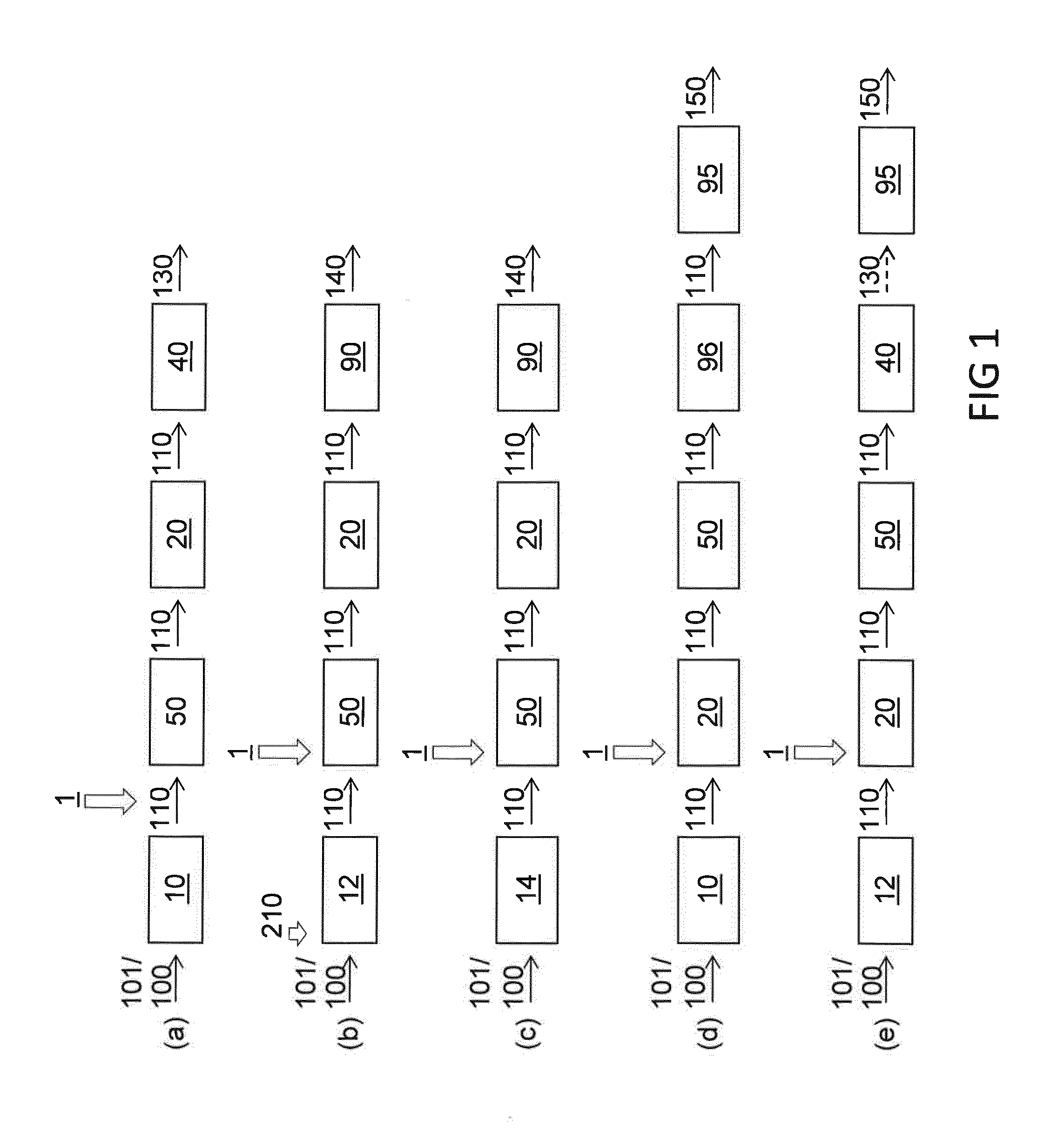

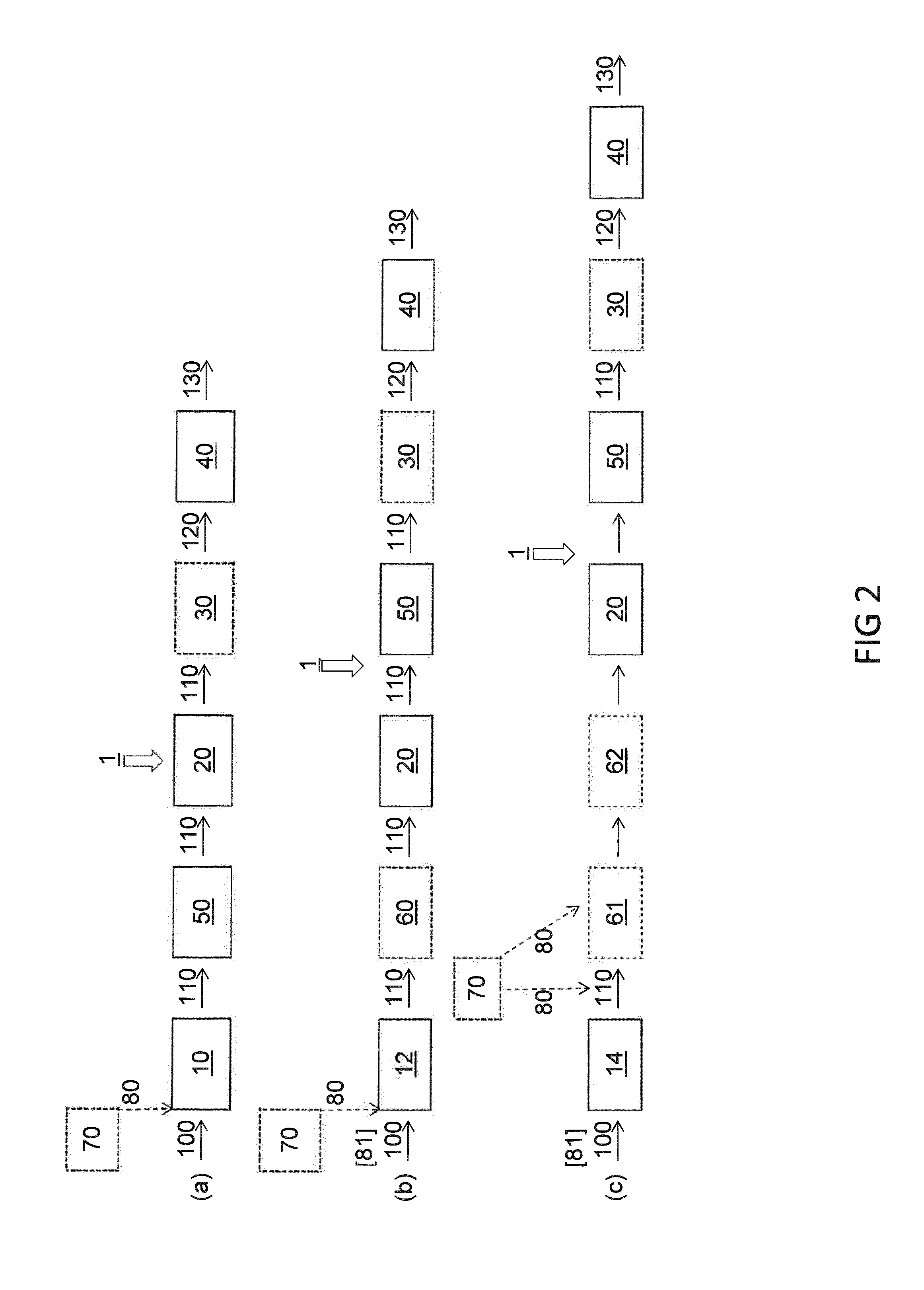

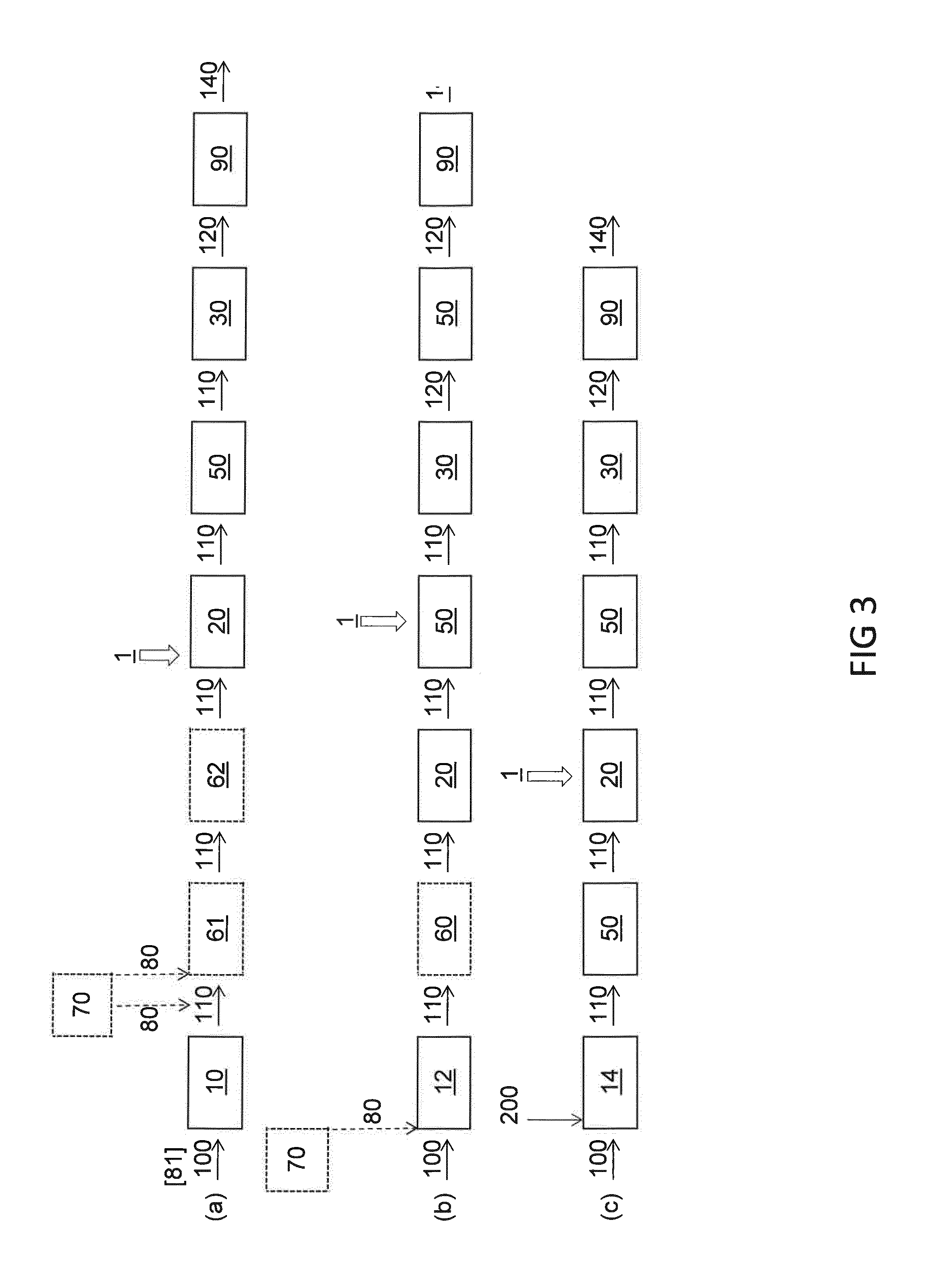

A Process to Recycle Expandable Plastic Materials and an Expandable or Expanded Plastic Material Obtainable Thereby

ActiveUS20160375616A1Less investmentSmall footprintPlastic recyclingShell moldingBiomedical engineering

A process is disclosed to recycle and / or formulate expandable plastic materials using a system (1) comprising: an extruder unit (10), a mixer-heat exchanger unit (20), said process comprising the steps of: melting in the extruder unit (10), cooling in the mixer-heat exchanger unit (20), and controlling the melt pressure by means of a melt pump unit (50), followed by granulation, extrusion, or injection molding, wherein a first expansion agent (81) is not degassed during a melt processing in the system (1) such that it is substantially contained in the granulated expandable plastic material (130) or used to form either the extruded, formed and expanded plastic material (140) or the molded expanded plastic article (150). The present invention also relates to a granulated expandable plastic material (130), an extruded, formed and expanded plastic material (140), and a molded expanded plastic article (150) obtainable by said process.

Owner:SULZER MANAGEMENT AG

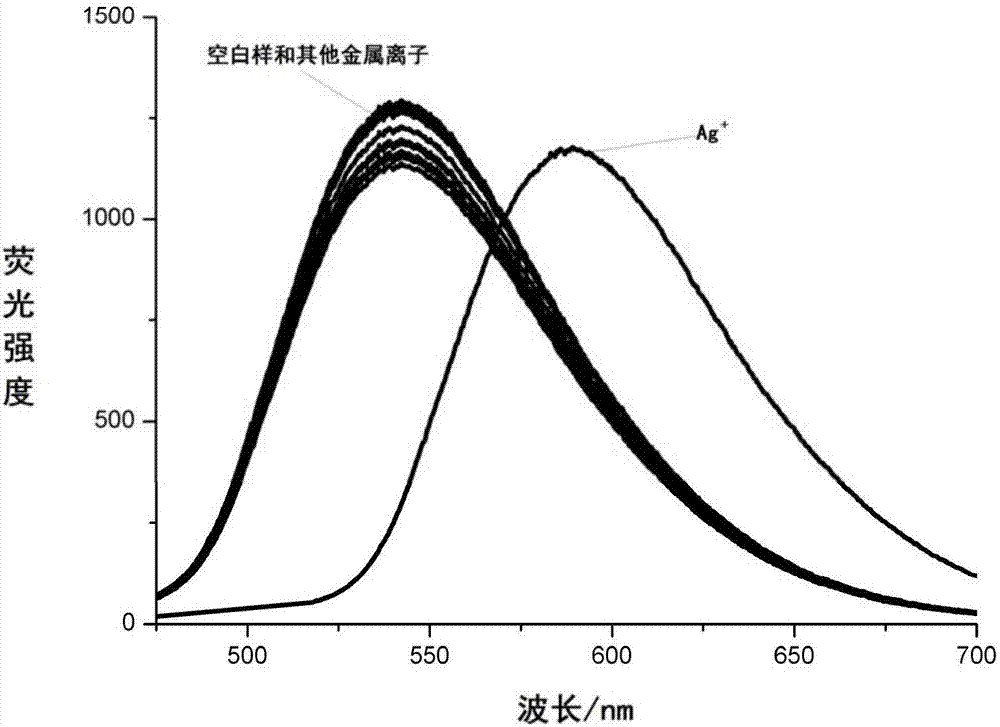

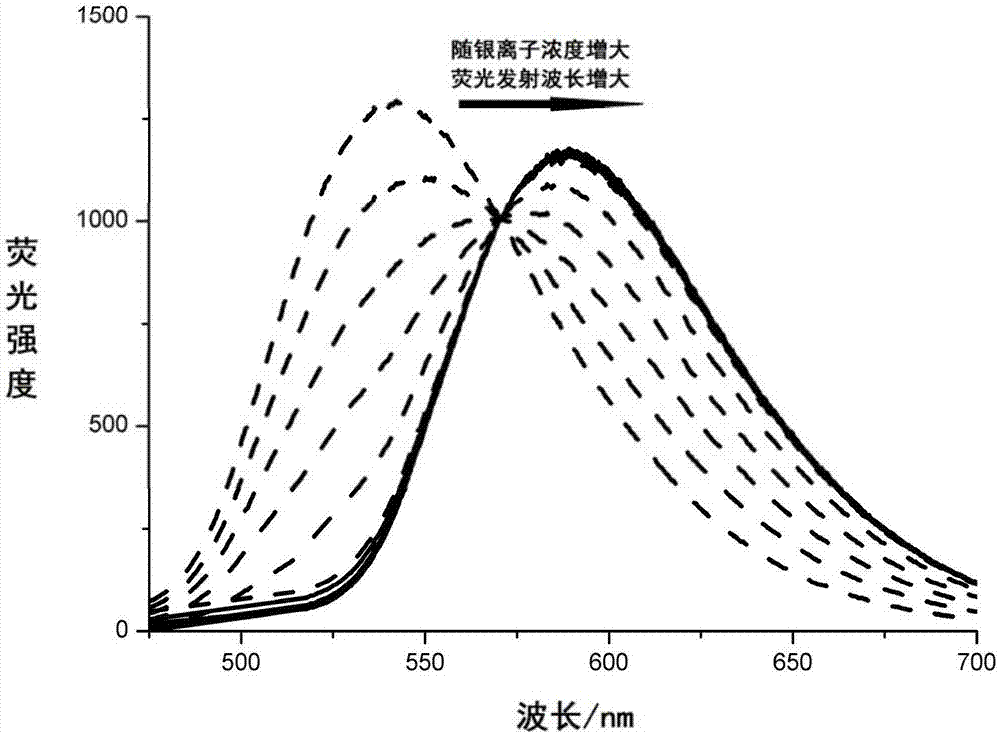

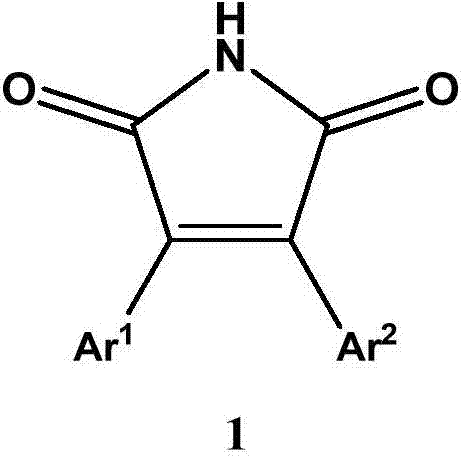

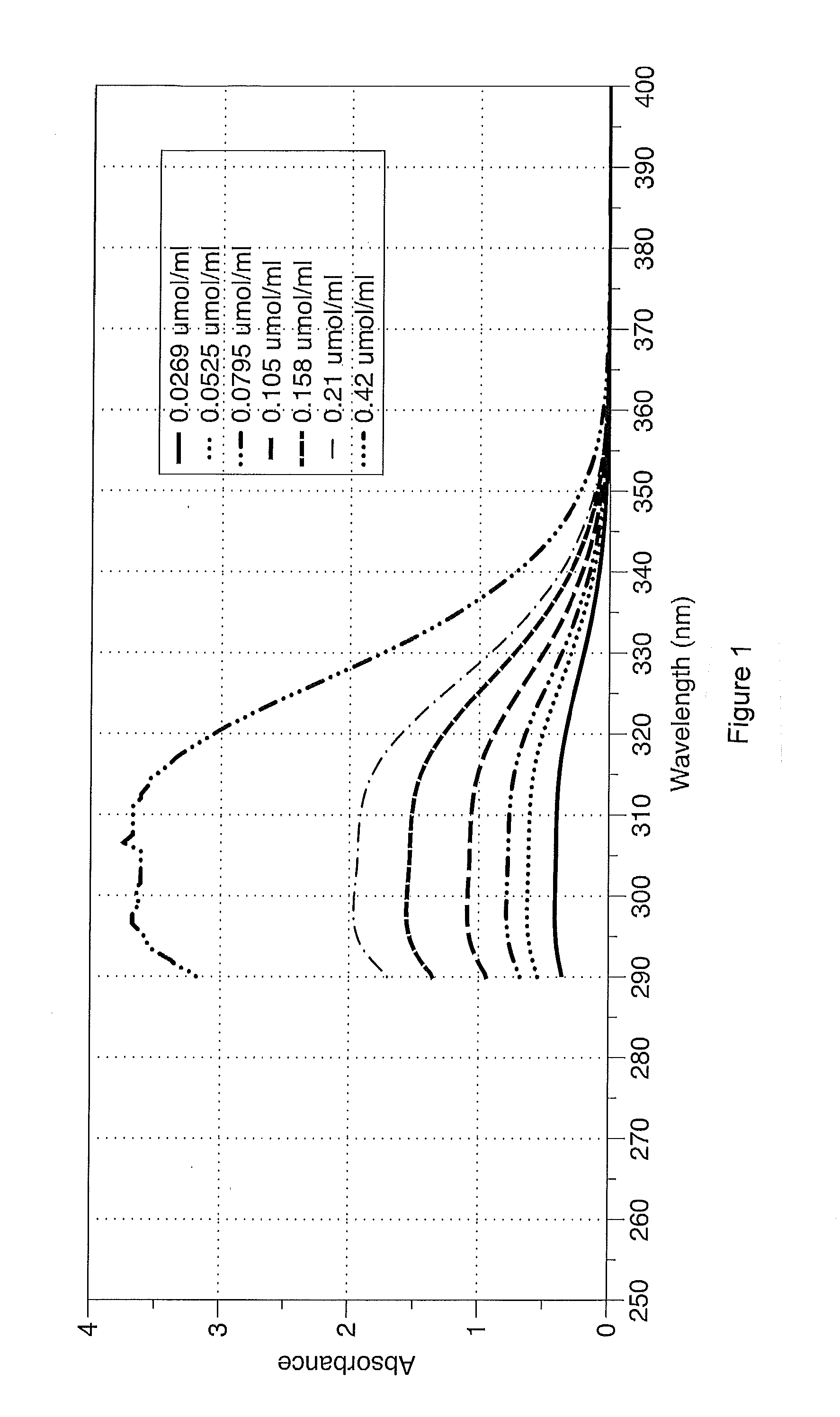

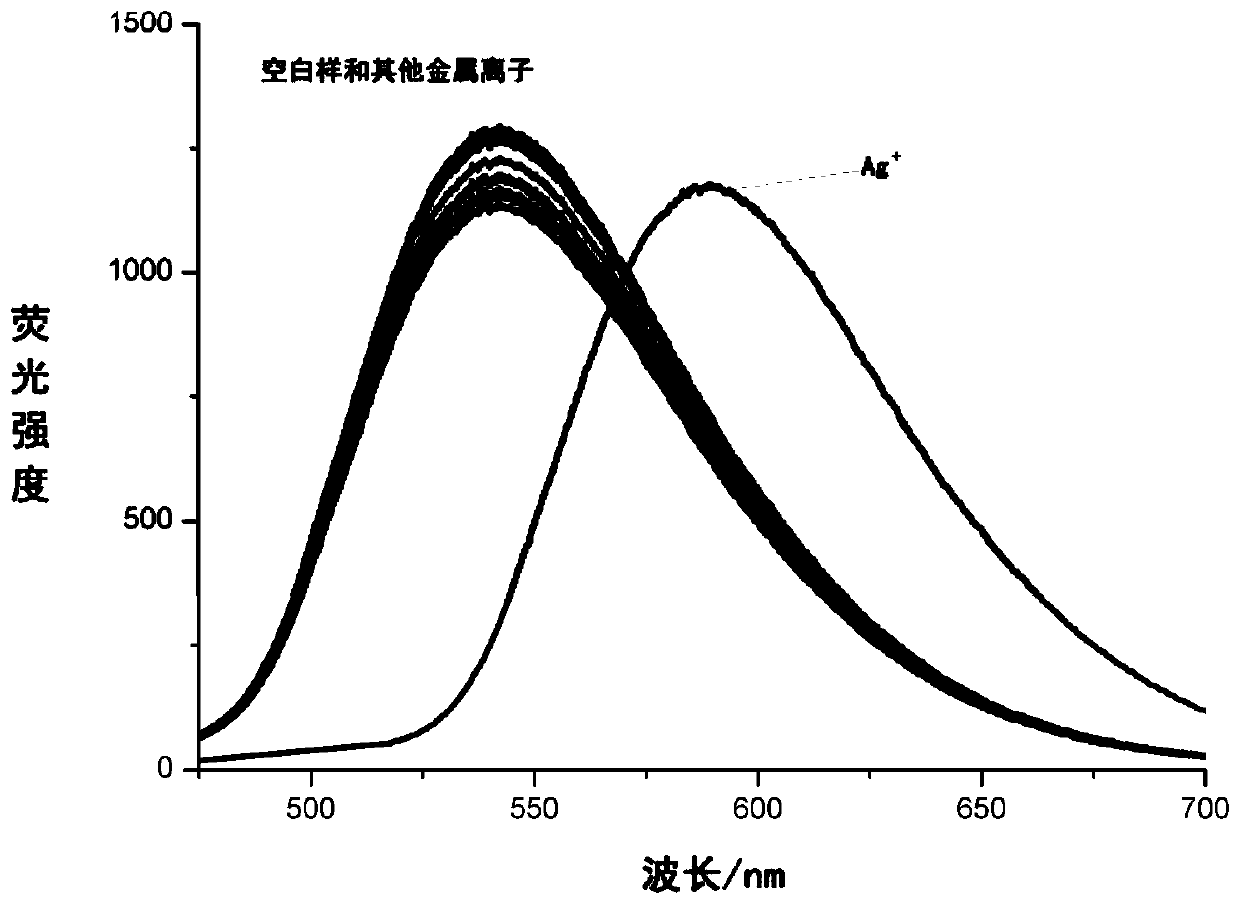

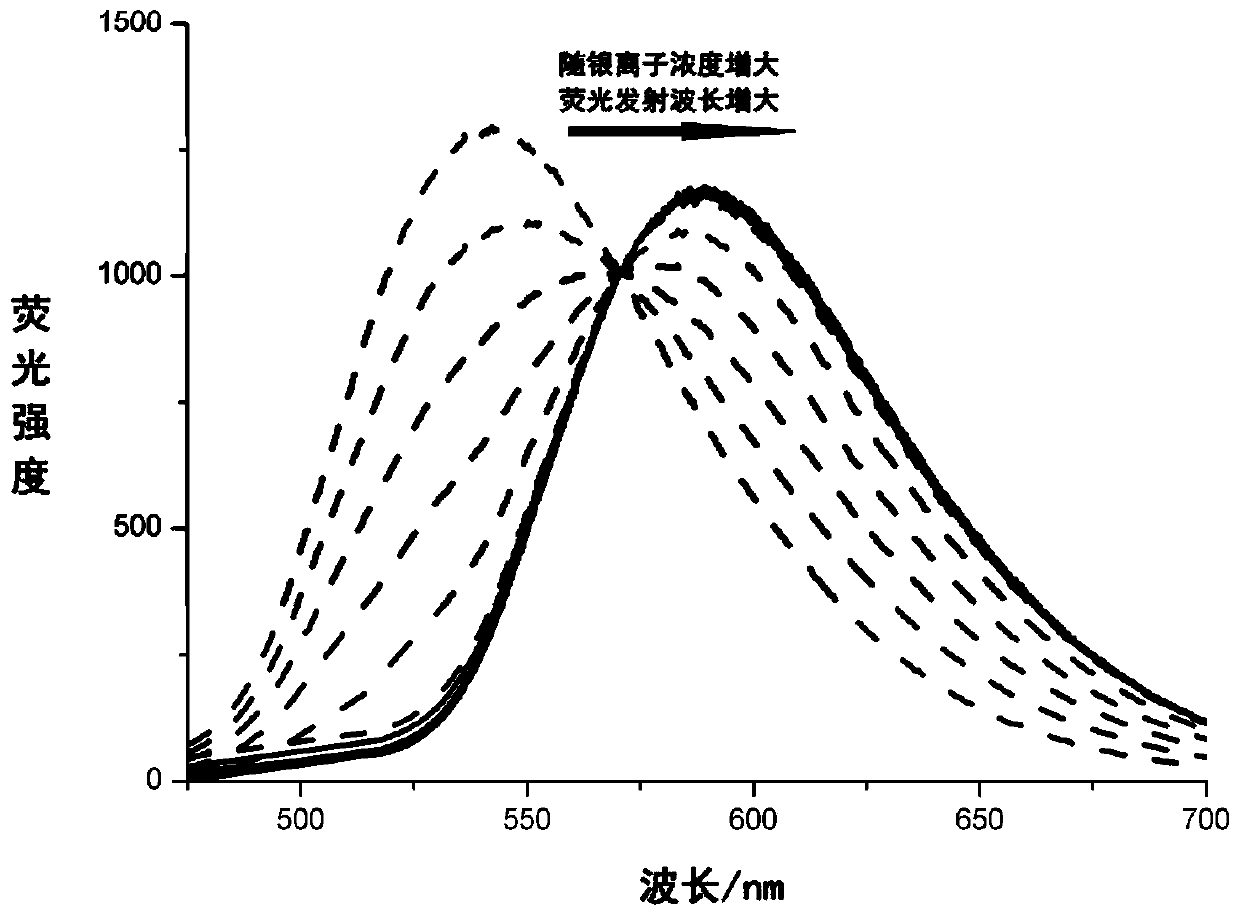

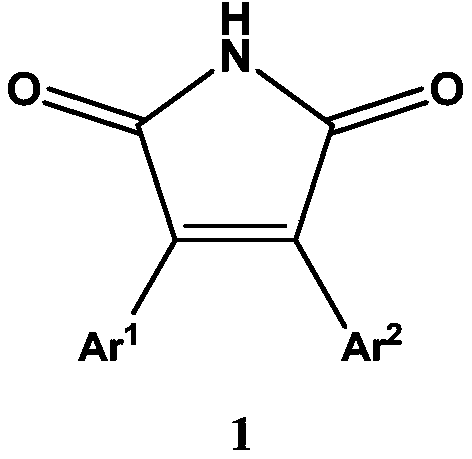

Fluorescence probe for detecting silver ion as well as preparation method and application thereof

ActiveCN107973785AGood choiceImprove featuresOrganic chemistryFluorescence/phosphorescenceLinear correlationFluorescence

The invention discloses a fluorescence probe for detecting a silver ion, and provides a preparation method and application thereof at the same time. The fluorescence probe can quickly respond and high-selectively detect the silver ion. The fluorescence probe for detecting the silver ion provided by the invention has a structure as shown in a formula 1. The probe provided by the invention can selectively react with the silver ion so as to produce fluorescence-emission red shift. The reaction is not interfered by other metal ions, a fluorescence-emission peak change can be produced within a short time, and the wave length of the fluorescence-emission peak red shift is in linear correlation with the concentration of the silver ion. The fluorescence probe provided by the invention only carriesout fluorescence reaction with the silver ion instead of other metal ions, so that the fluorescence probe has better selectivity and specificity.

Owner:浙江工业大学上虞研究院有限公司

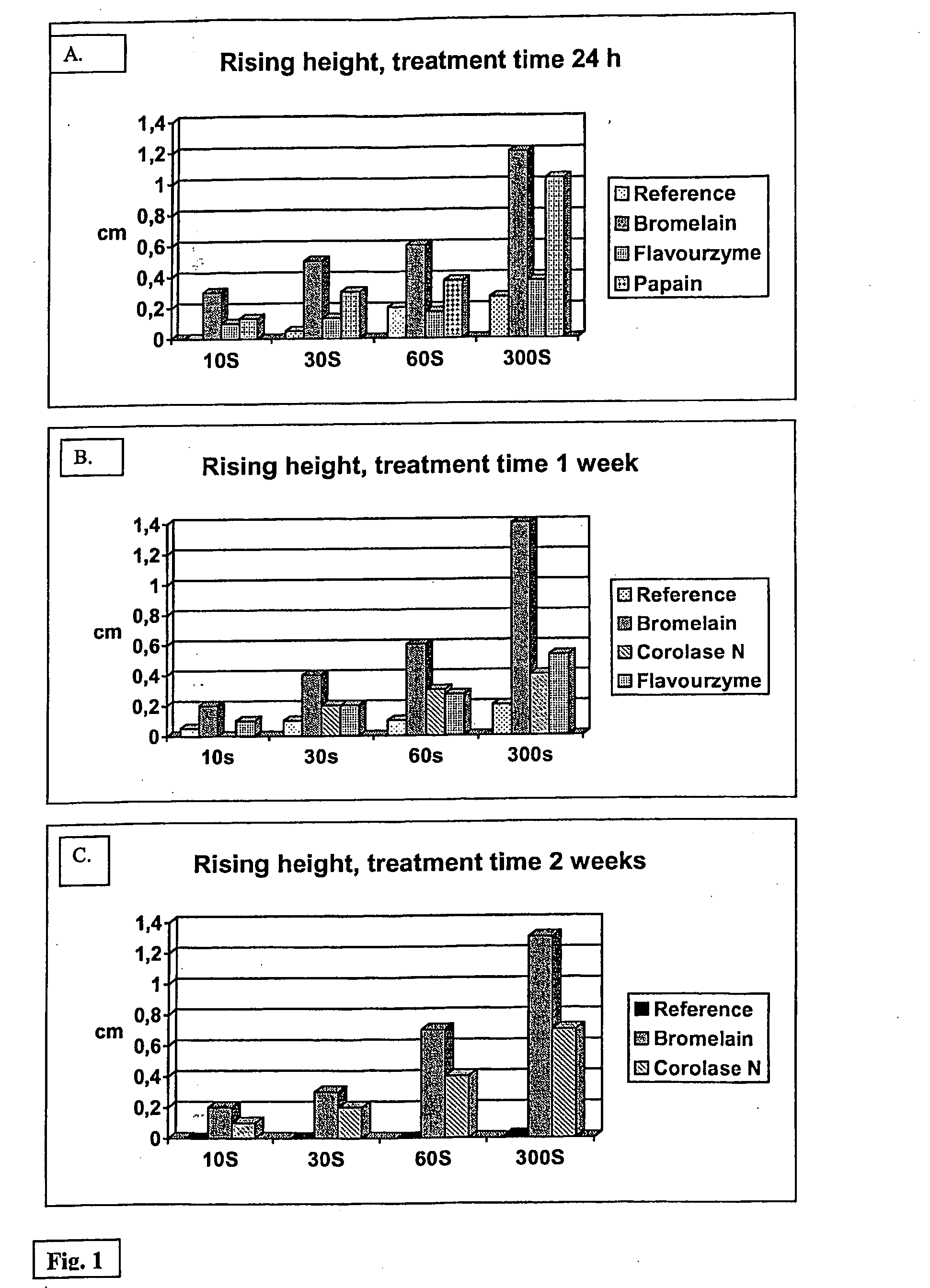

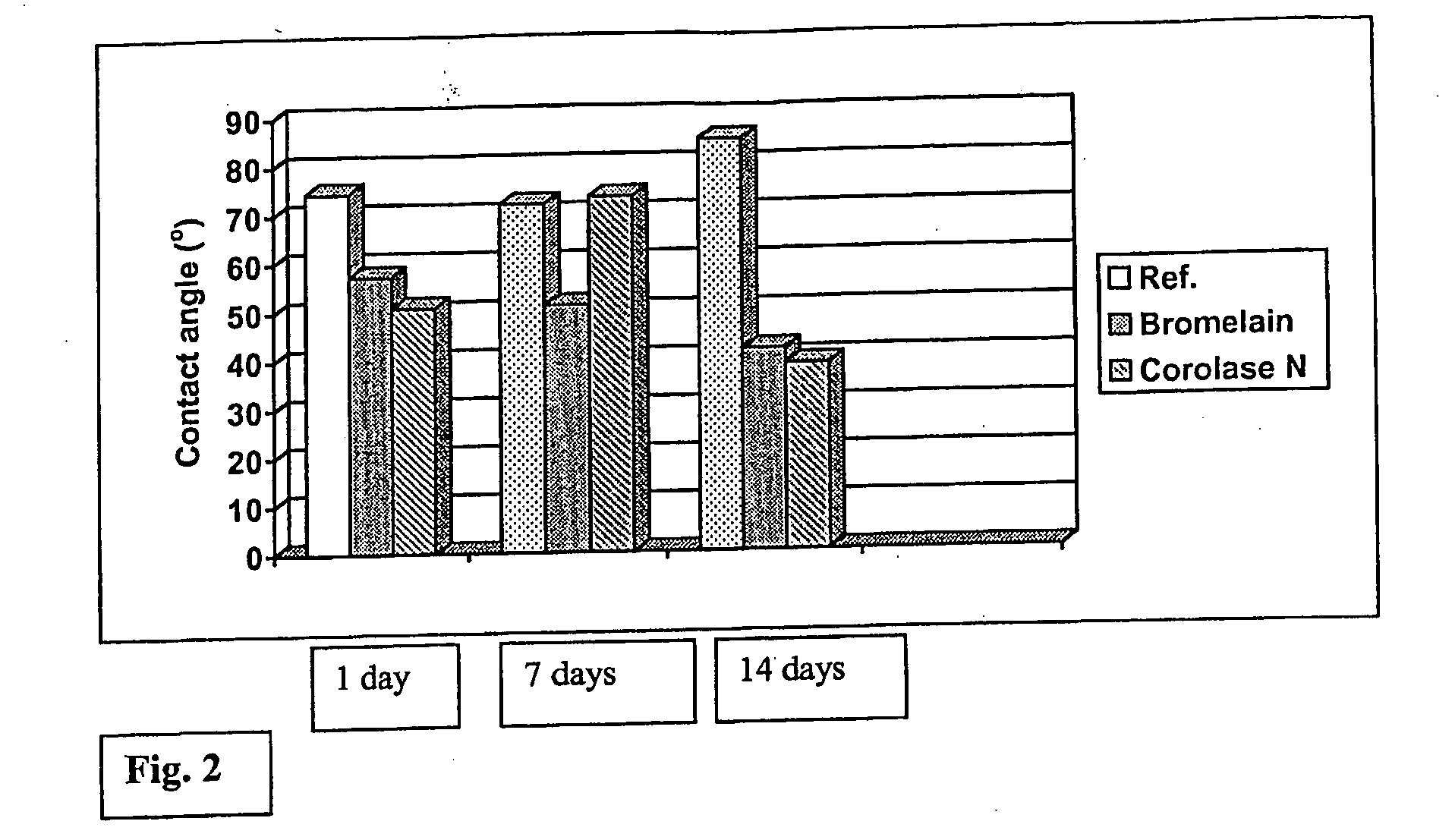

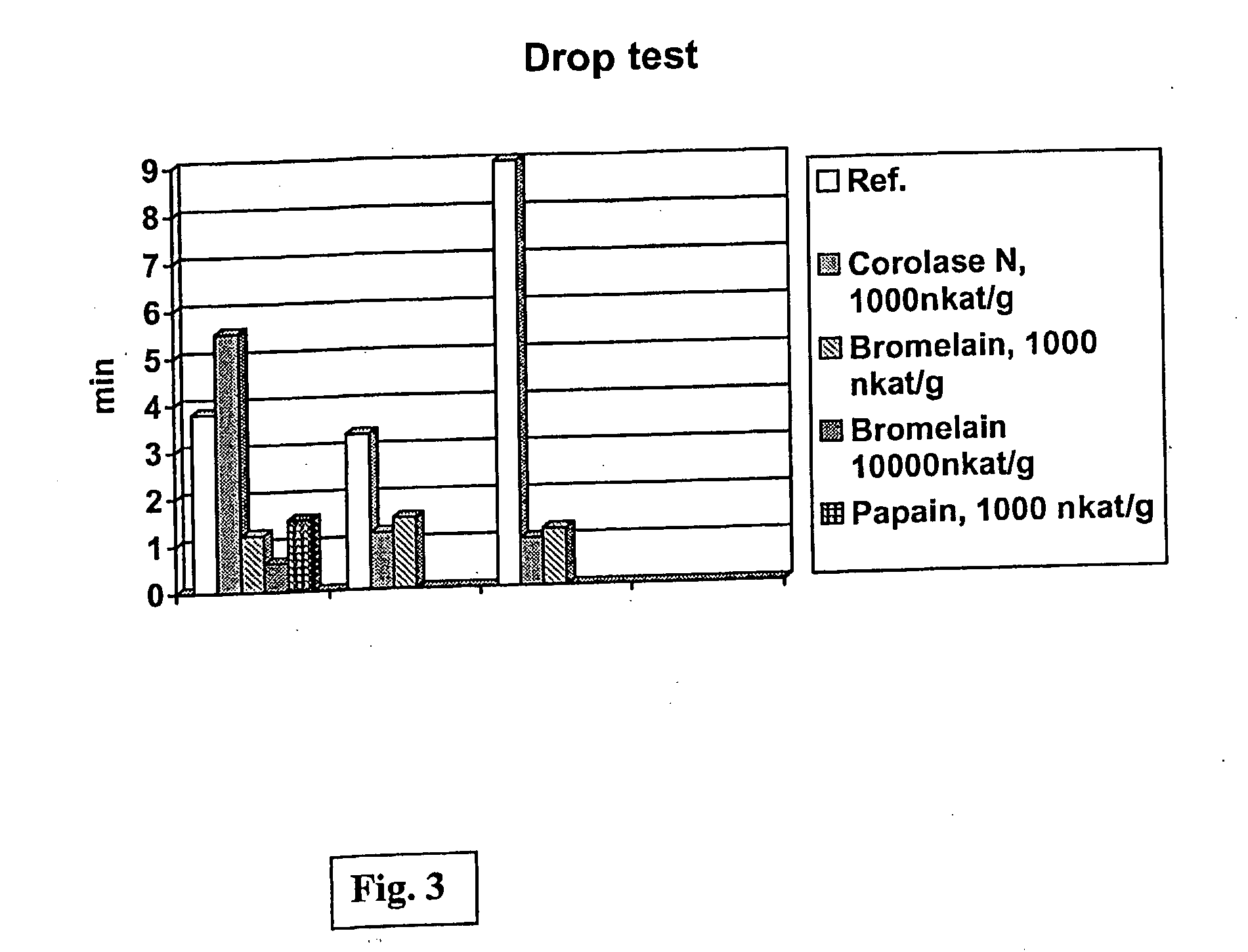

Method for Modifying Polyamide

InactiveUS20080289120A1Less harmful to the environmentImproves end-product propertyFibre typesReactive dyesProteinase activityPolyamide

The present invention relates to a method for modifying polyamide. The method comprises that polyamide is contacted with an enzyme preparation comprising an effective amount of protease enzyme in aqueous environment under conditions suitable for the function of the enzyme. The enzyme is preferably selected from the group of aspartic proteases, cysteine proteases and metallo-proteases.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

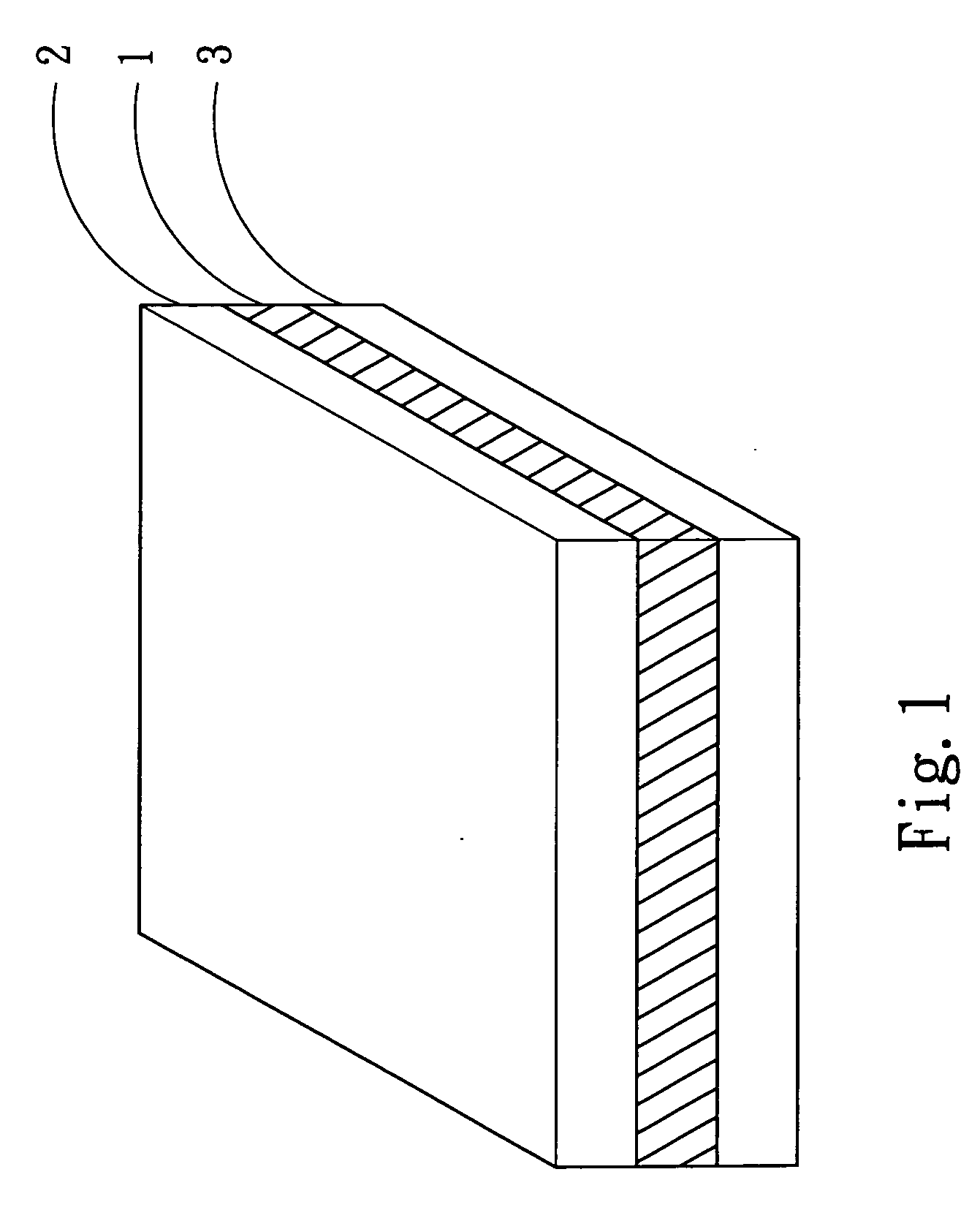

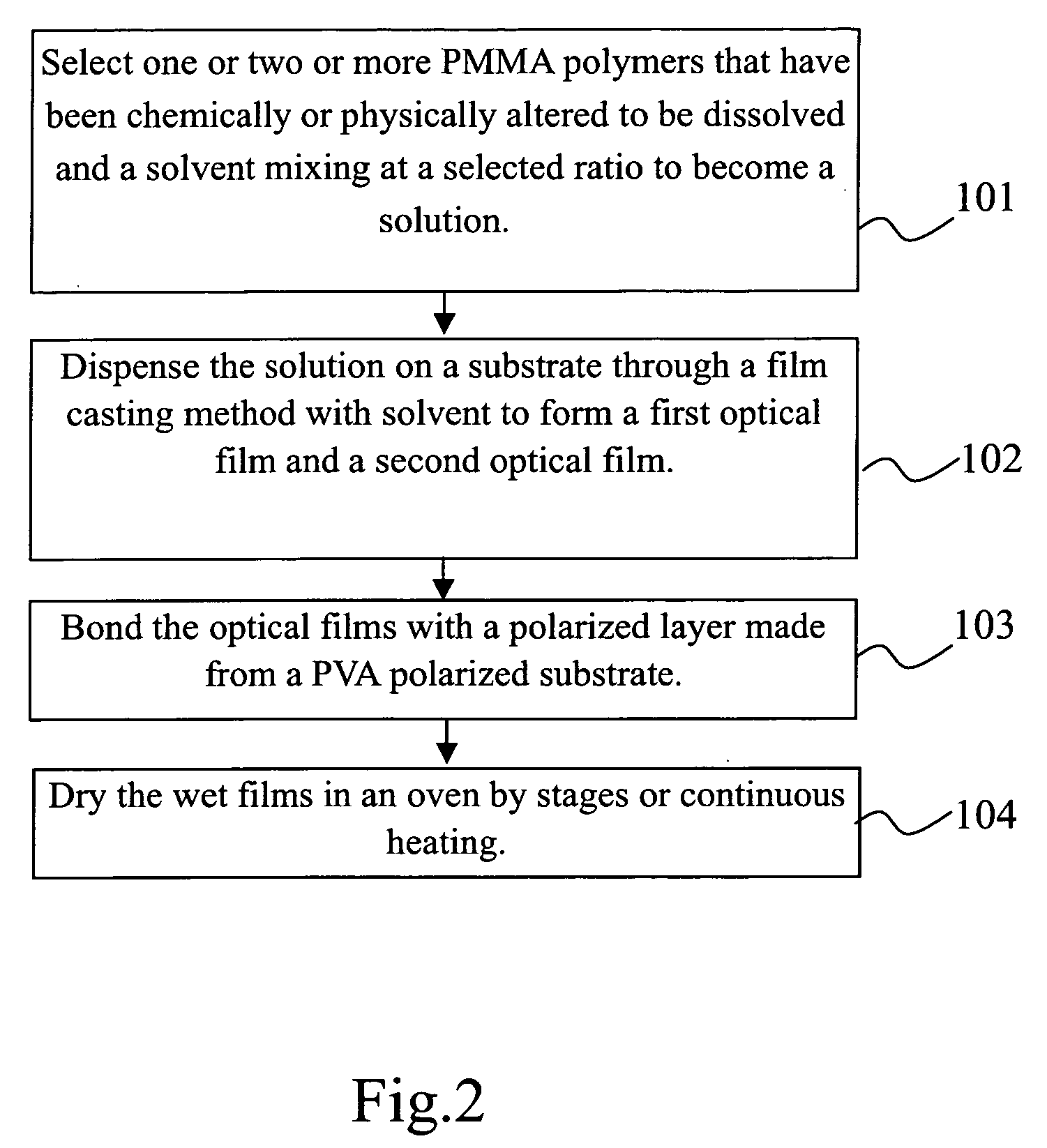

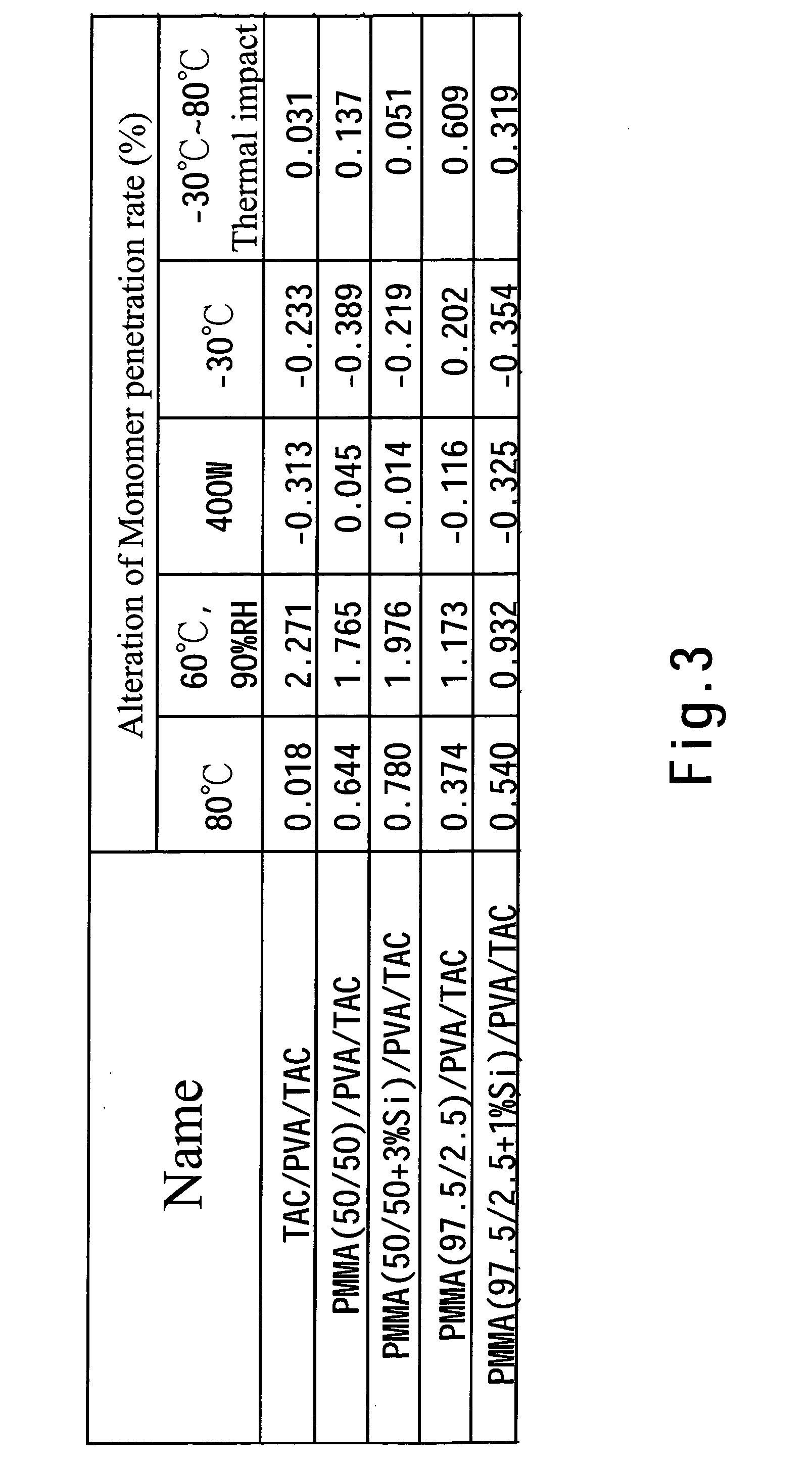

Polarized plate

InactiveUS20070172686A1Excellent mechanical propertiesLess harmful to the environmentSynthetic resin layered productsThin material handlingHeat treatedPhysics

A polarized plate includes a polarized layer, a first optical film located on a upper side of the polarized layer and a second optical film located on a lower side of the polarized layer. At least one of the first and second optical films is made from Polymethyl Methacrylate (PMMA). The optical films are formed by dispensing a mixed solution on a substrate, then bonding to the polarized layer and processed through a heat treatment. The optical films may also be formed by dispensing the mixed solution on the surface of the polarized layer and processed through a heat treatment.

Owner:OPTIMAX TECHNOLOGY CORPORATION

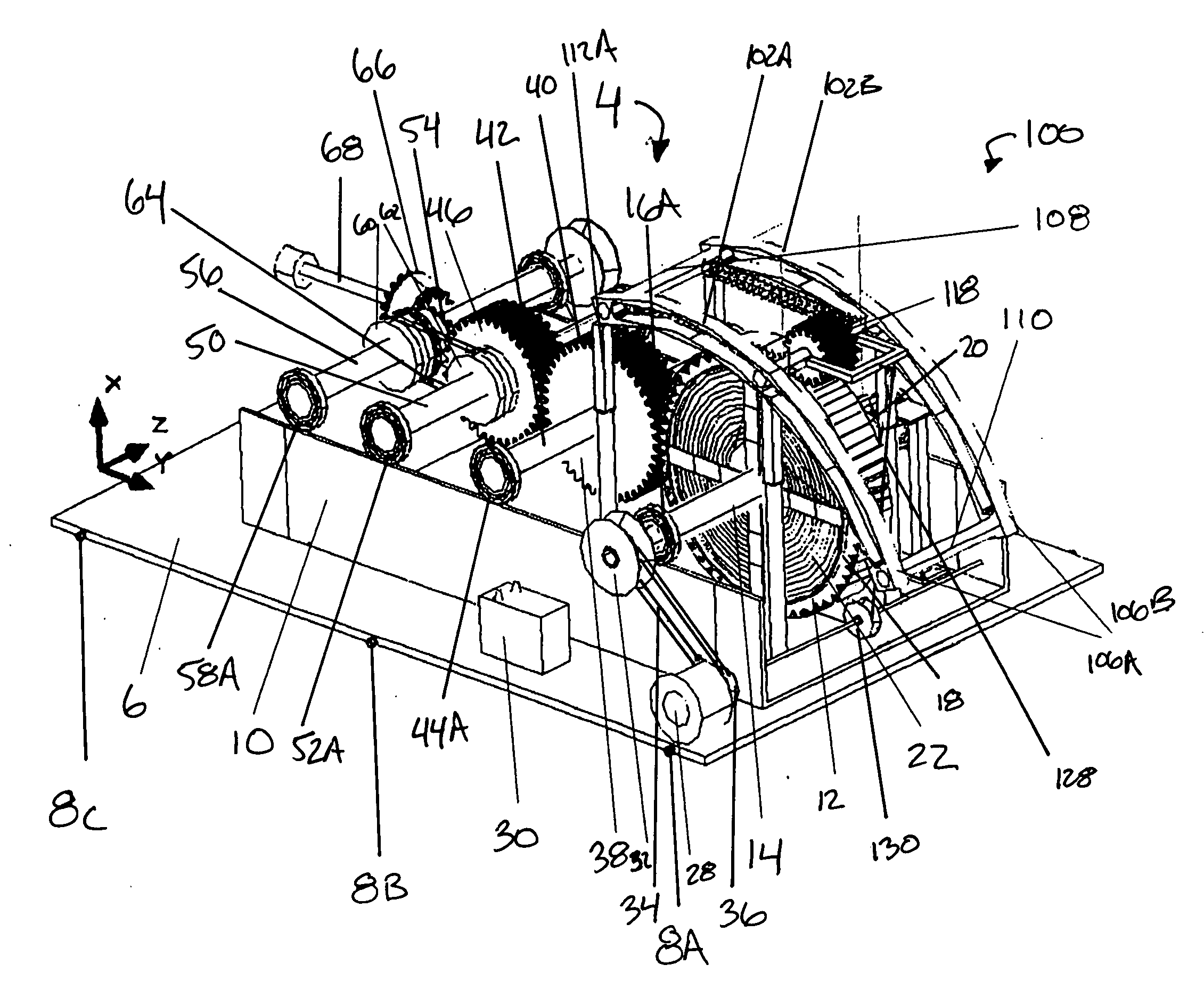

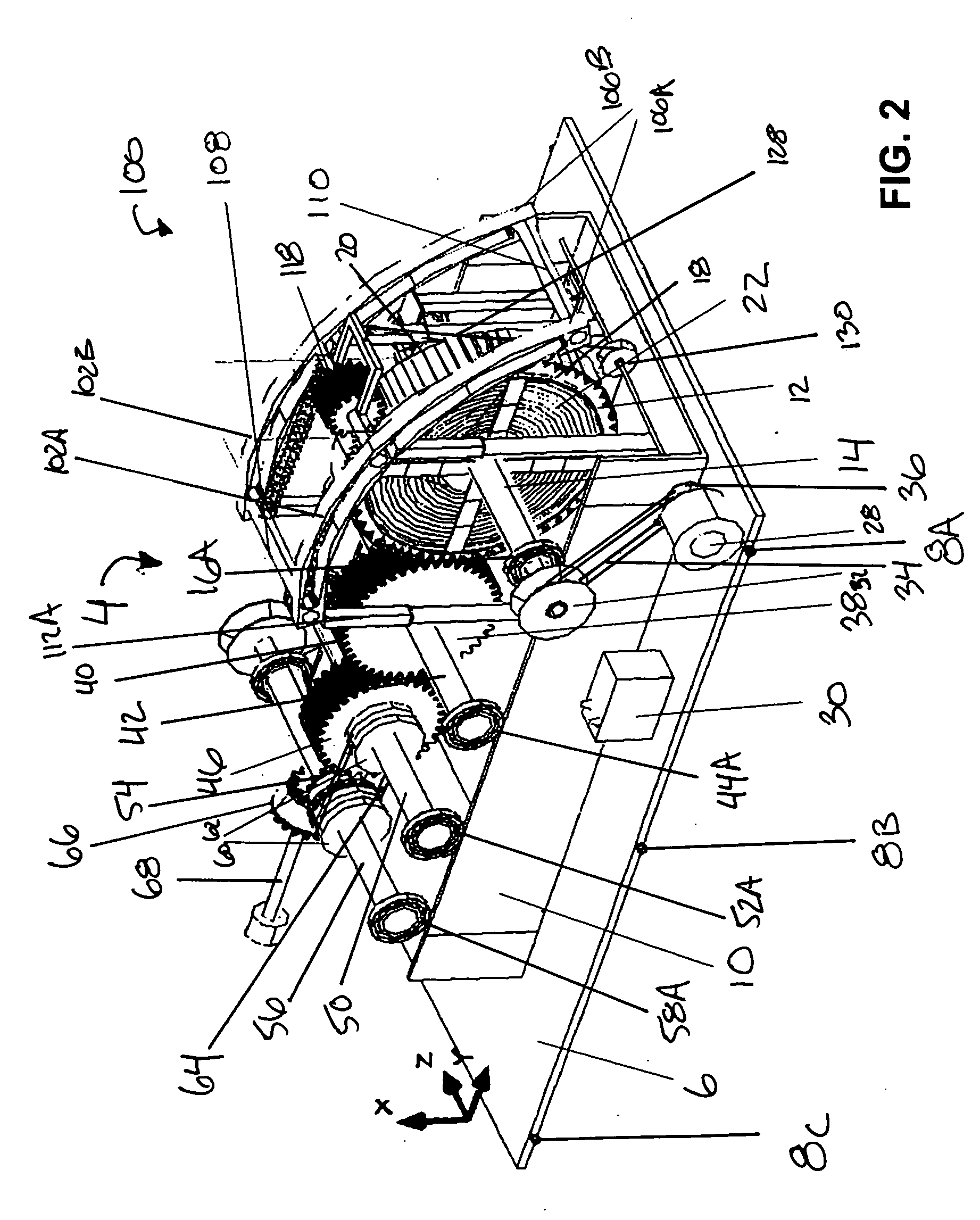

Spring powered engine

InactiveUS20080190701A1Less noisyLess harmful to the environmentSpring motorMachines/enginesGear wheelDrive shaft

A spring powered engine comprising a first gear having a cylindrical outer casing with gear threads positioned on a radial circumference of the outer casing. A rotatable first gear shaft is positioned through the outer casing and a spring coil is disposed within the outer casing, the spring coil having one end fixed to the first gear shaft and another end fixed to an inner circumference of the cylindrical outer casing. A motor is provided to wind the coil spring, and the uncoiling of the coil spring rotates the first gear which, through a series of gears and pulleys, rotates a transmission shaft to power a vehicle.

Owner:STAVROPOULOS JOHN P

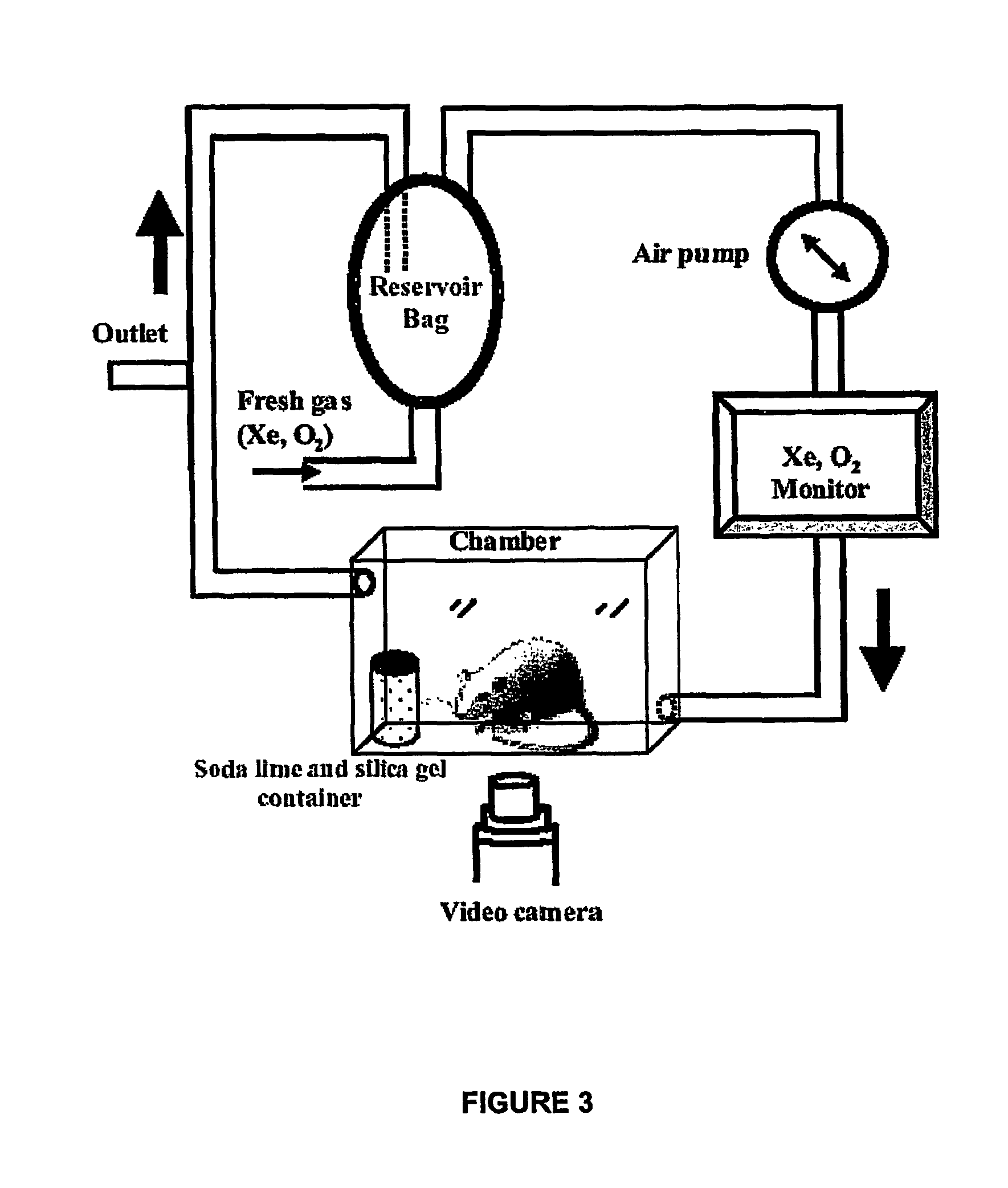

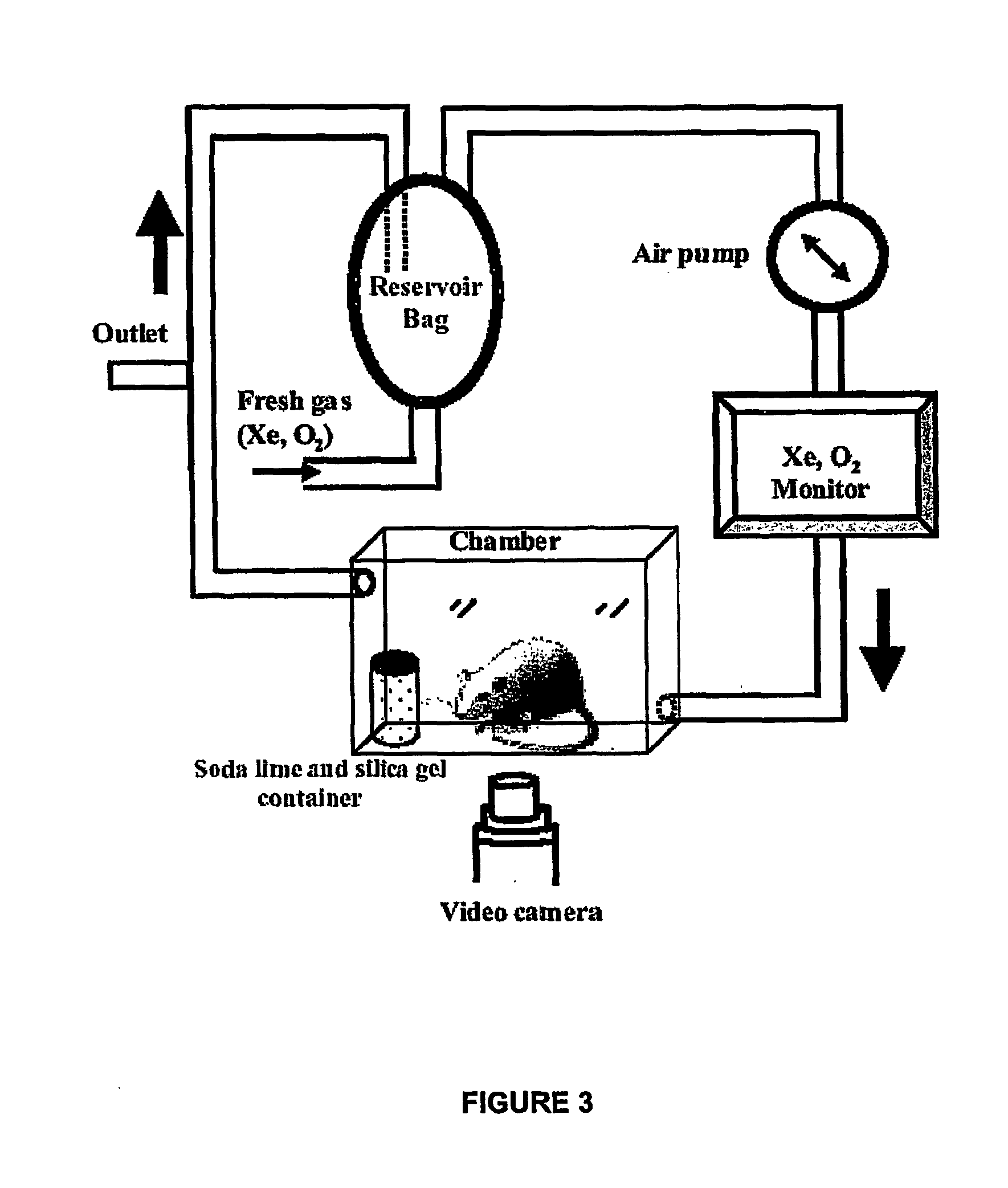

Analgesic agent for newborn or fetal subjects

InactiveUS7632872B2Total current dropFast induction and emergenceBiocideNervous disorderObstetricsAnalgesic agents

In a first aspect, the present invention relates to the use of xenon in the preparation of a medicament for providing analgesia in a newborn subject and / or a fetal subject. In a second aspect, the invention relates to a method of providing analgesia in a newborn subject, the method comprising administering to the subject a therapeutically effective amount of xenon. In a third aspect, the invention relates to a method of providing analgesia in a fetal subject, the method comprising administering to the mother of the fetal subject a therapeutically effective amount of xenon for both the mother and fetal subject.

Owner:IP2IPO INNOVATIONS LTD

Shale oil and gas fracturing method with low environmental impact

InactiveUS20160090830A1Less harmfulLess harmful to the environmentFluid removalDrilling compositionParticulatesFracturing fluid

A method is provided for lowering the migration of a hydraulic fluid additive within a hydrocarbon-bearing formation penetrated by a well when producing hydraulic fracturing. Many chemical agents currently in use with water / sand (or other proppants) mixtures could pose human and animal health risks if these chemicals migrate from the shale beds into the environment contaminating the water table, rivers, streams and lakes. The fracturing fluid chemical additives employed are designed to be retained or anchored in or near the deep shale layers and are prevented, or greatly delayed from upward migration. Specifically, chemical additives required for proper fracturing fluid performance are covalently chemically bonded to inert particulate materials (e.g. silica having a particle size less than 2000 microns). The fracturing fluid chemical additives are thereby able to perform their function in the shale fracturing process, and thereafter become nearly permanently trapped in the shale layers protecting the environment above.

Owner:BATTELION ENERGY

Method for analysing amino acids and a reagent for use with the same

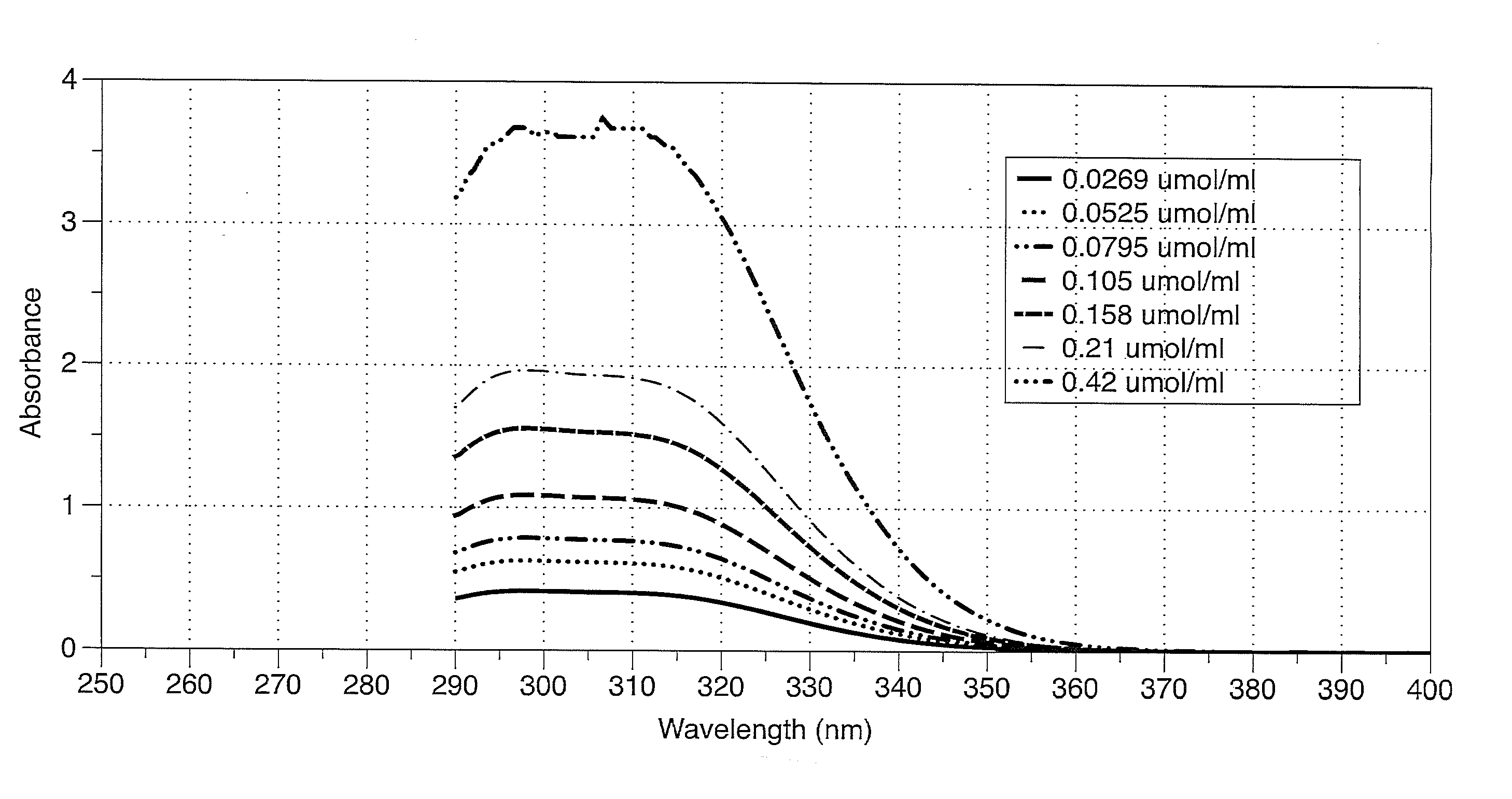

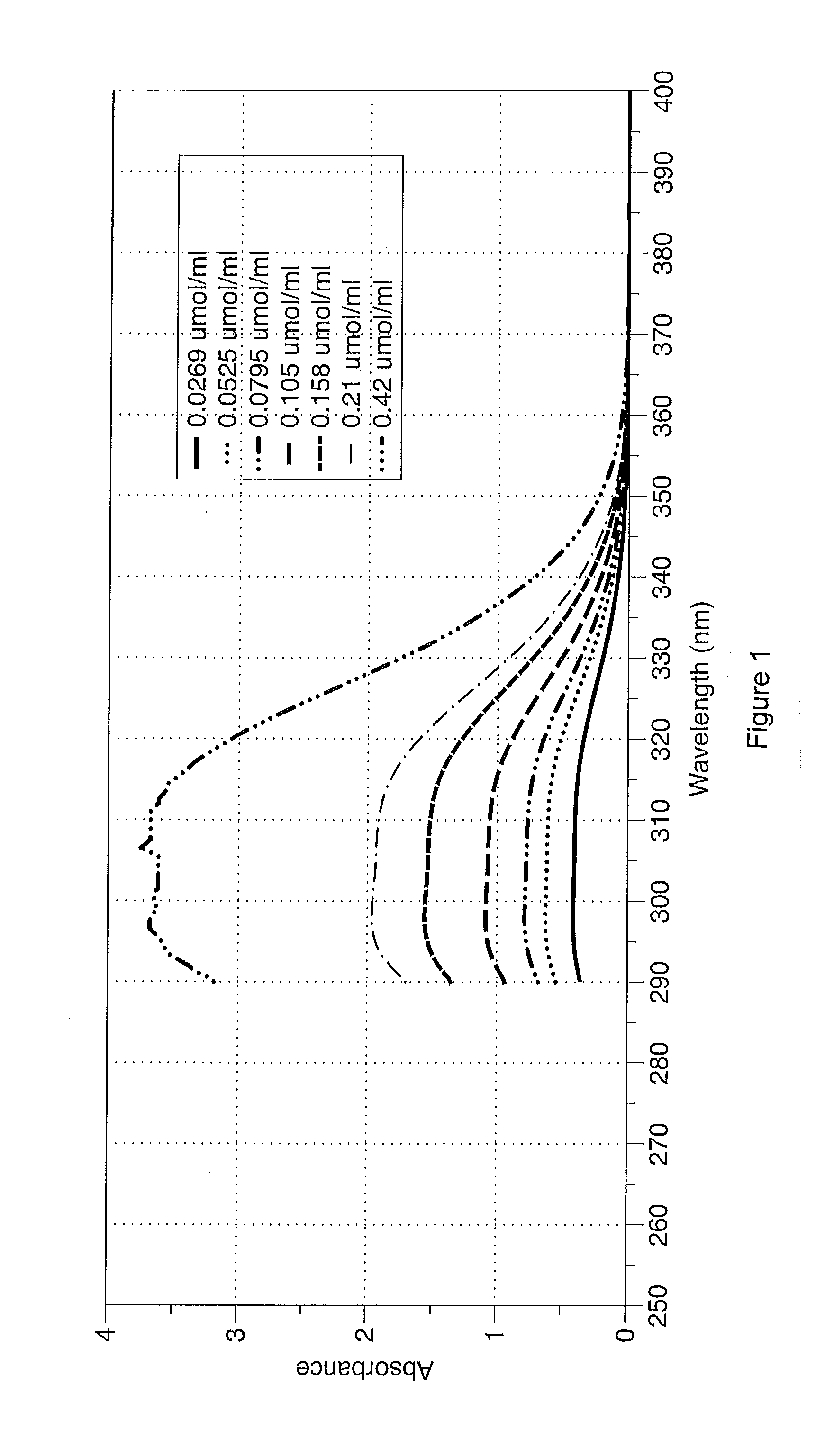

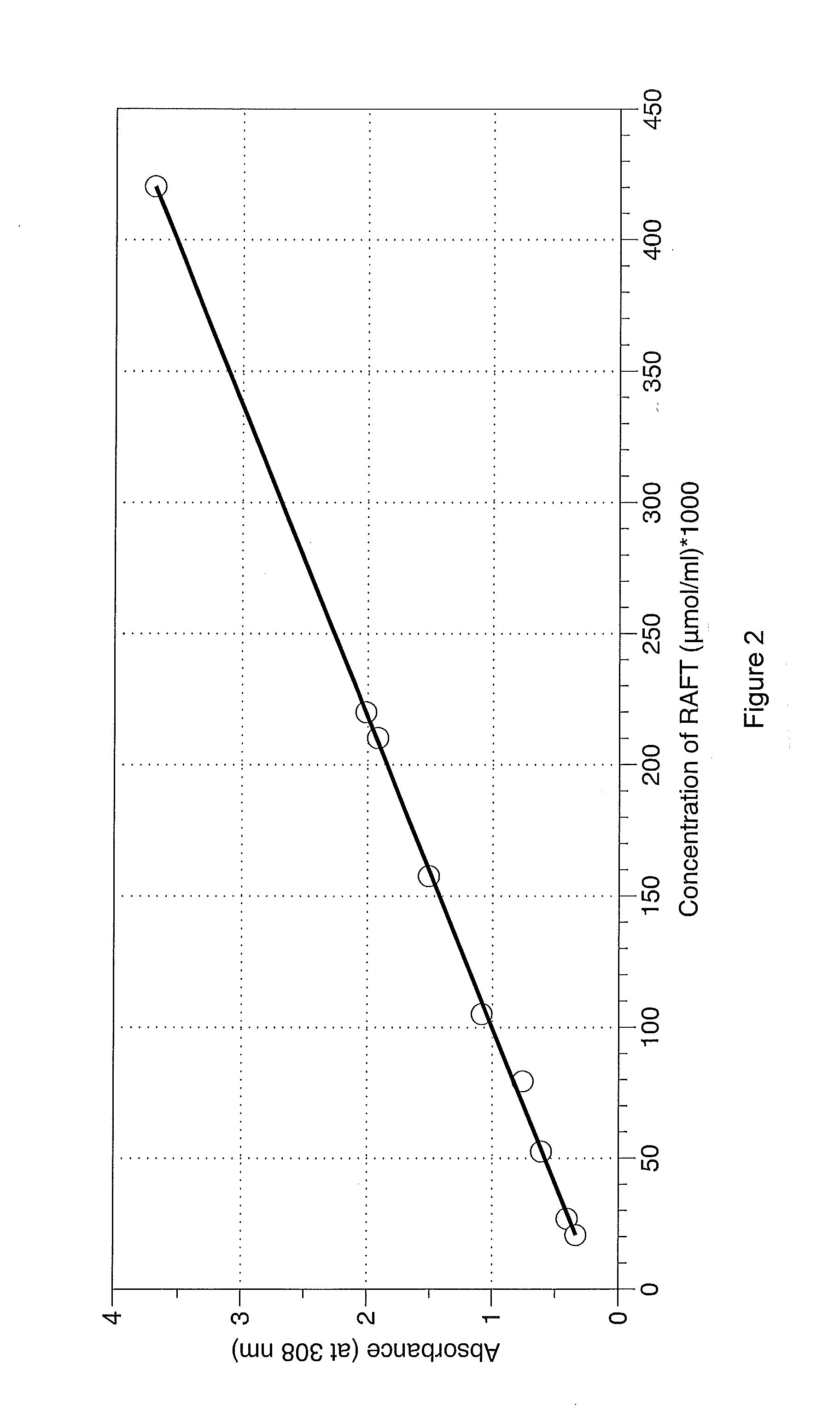

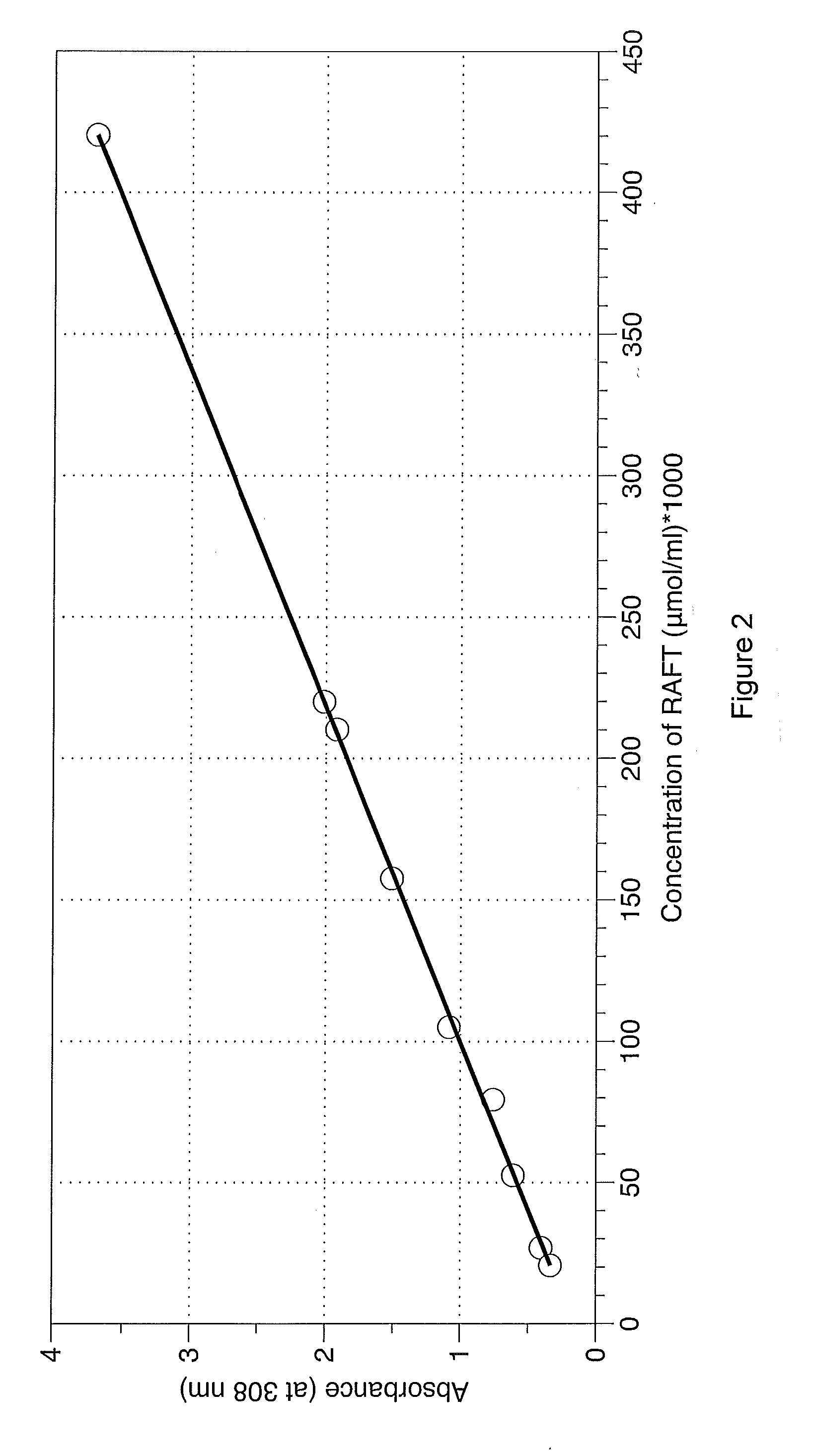

ActiveUS9250191B2Affects efficacyReduce riskIon-exchange process apparatusMaterial analysis by observing effect on chemical indicatorNitrogenContact zone

A method for analyzing one or more nitrogen-containing compounds, in which the one or more nitrogen-containing compounds are contacted with hydrindantin at an elevated temperature in a contact zone is provided. In the method ninhydrin is contacted with one or more reducing agents in a heating zone at a first elevated temperature to produce a hydrindantin-containing mixture. The hydrindantin-containing mixture is introduced into the contact zone and contacted with the nitrogen-containing compounds at a second elevated temperature. The method is particularly suitable for the analysis by visualization of amino acids.

Owner:JPP CHROMATOGRAPHY

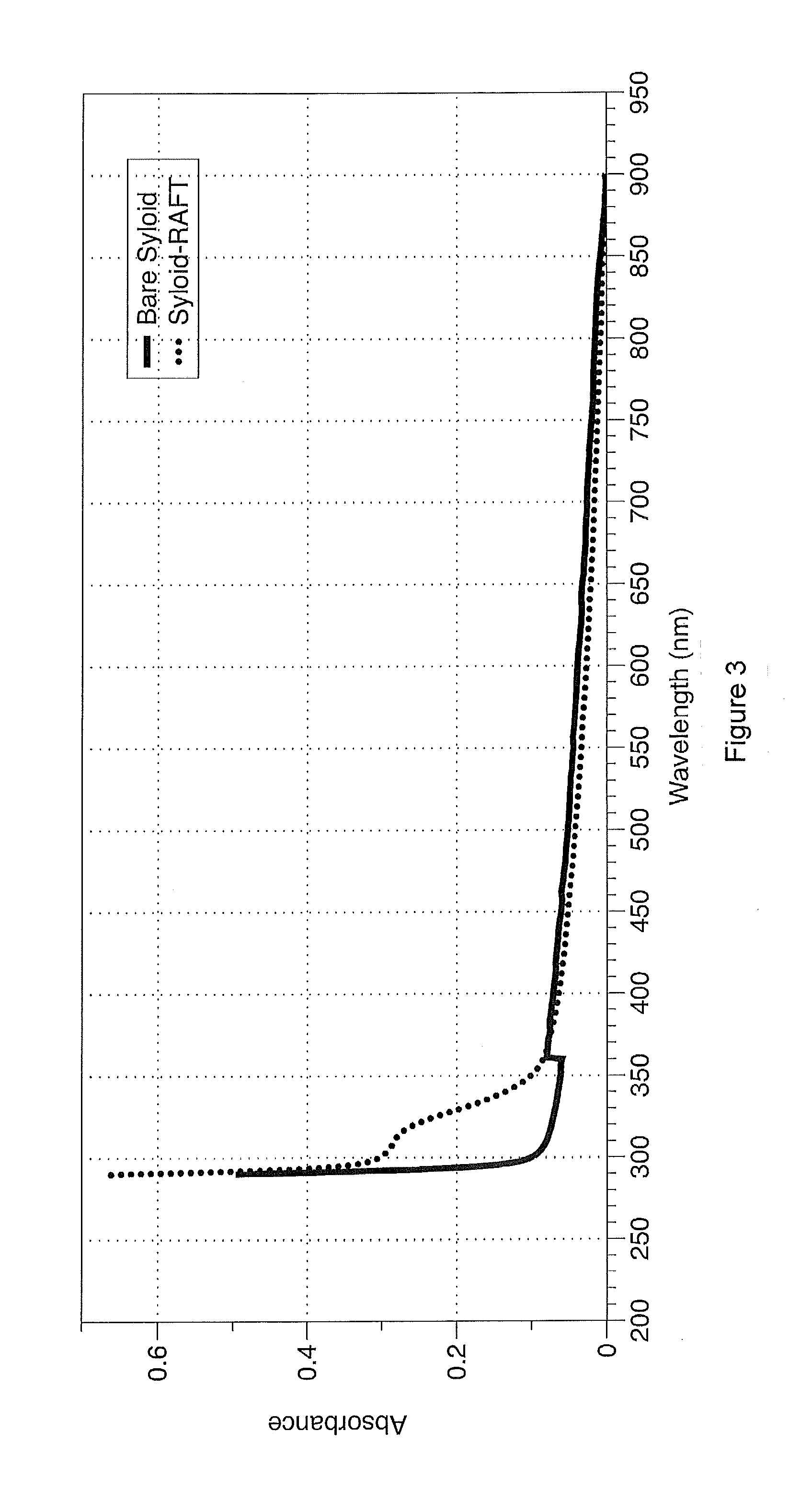

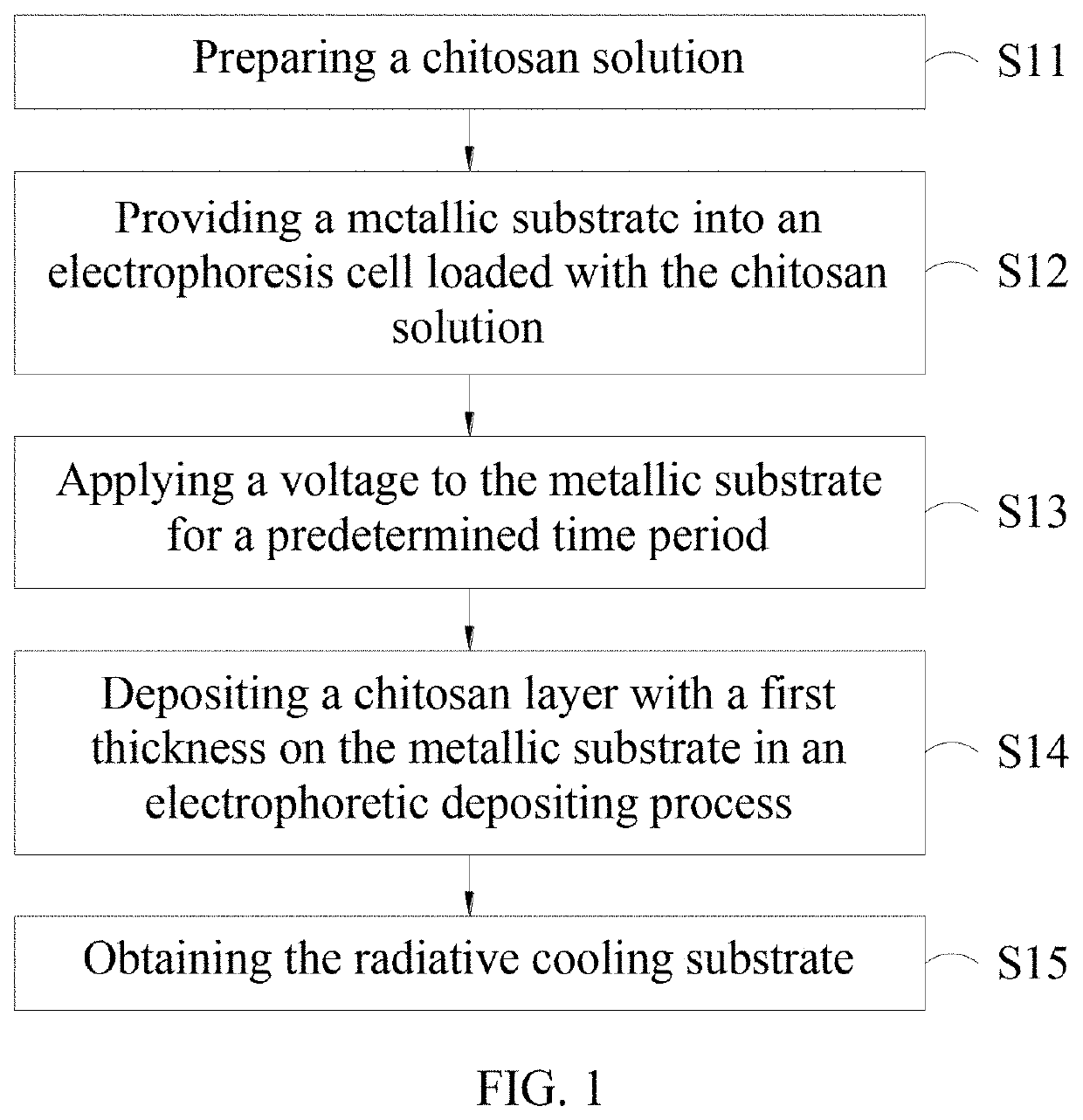

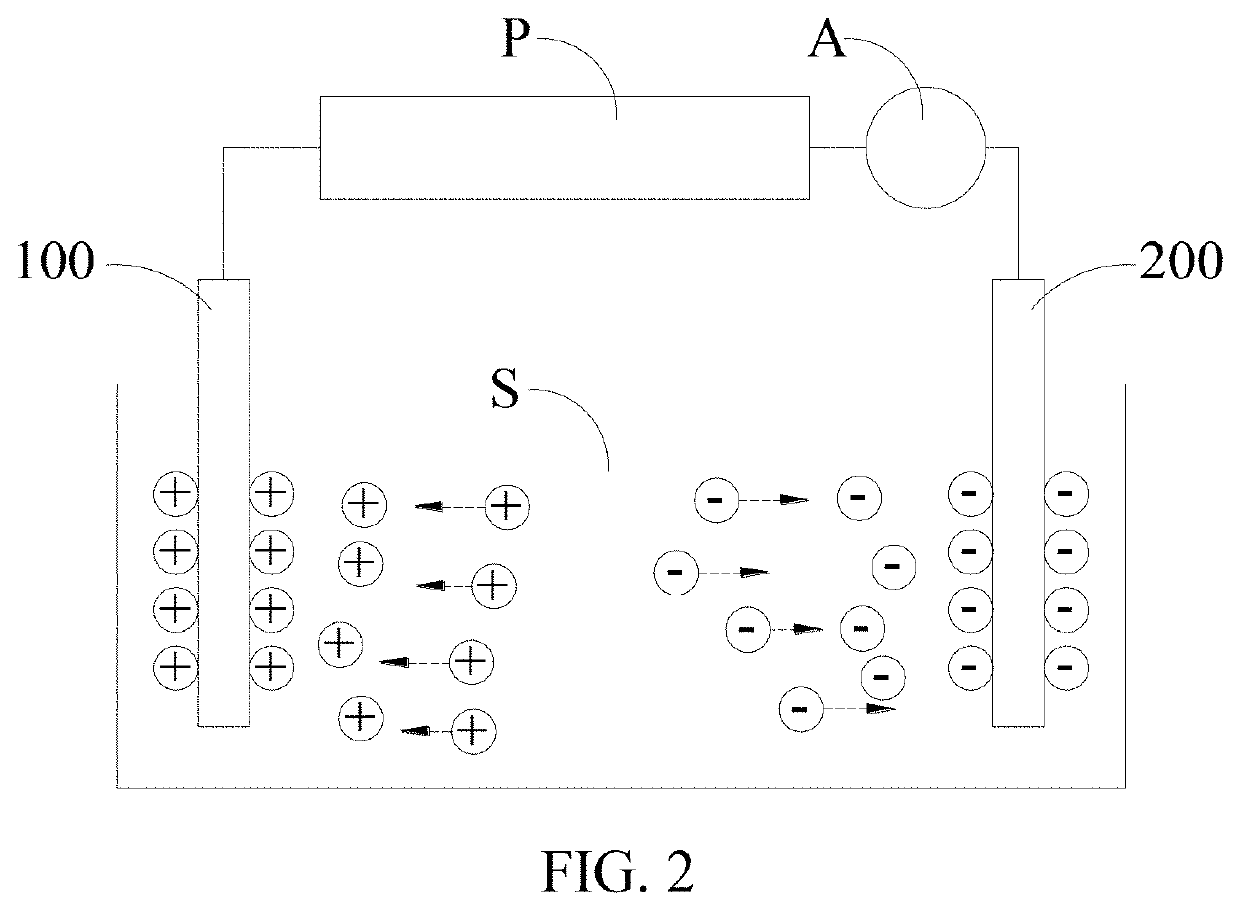

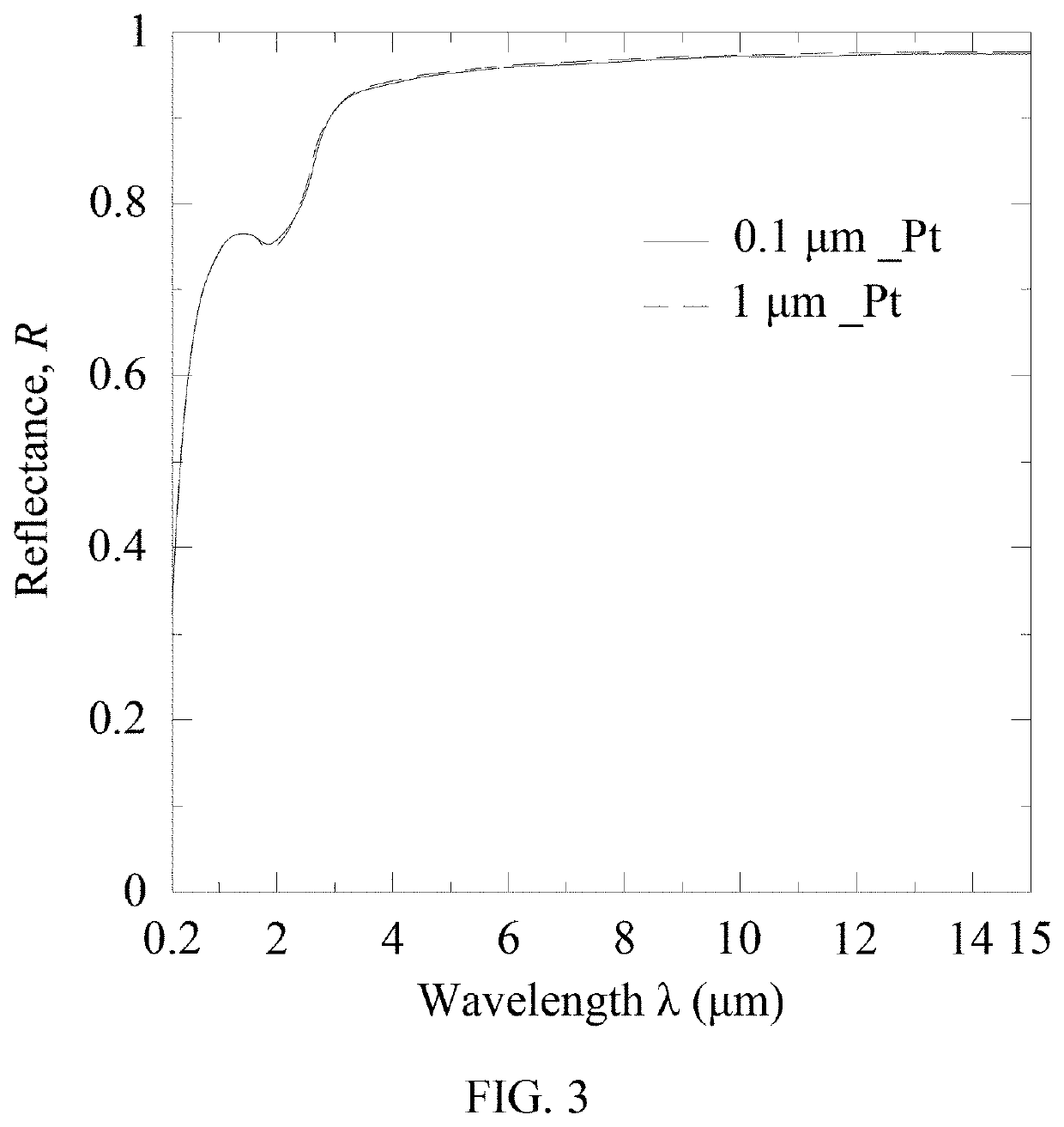

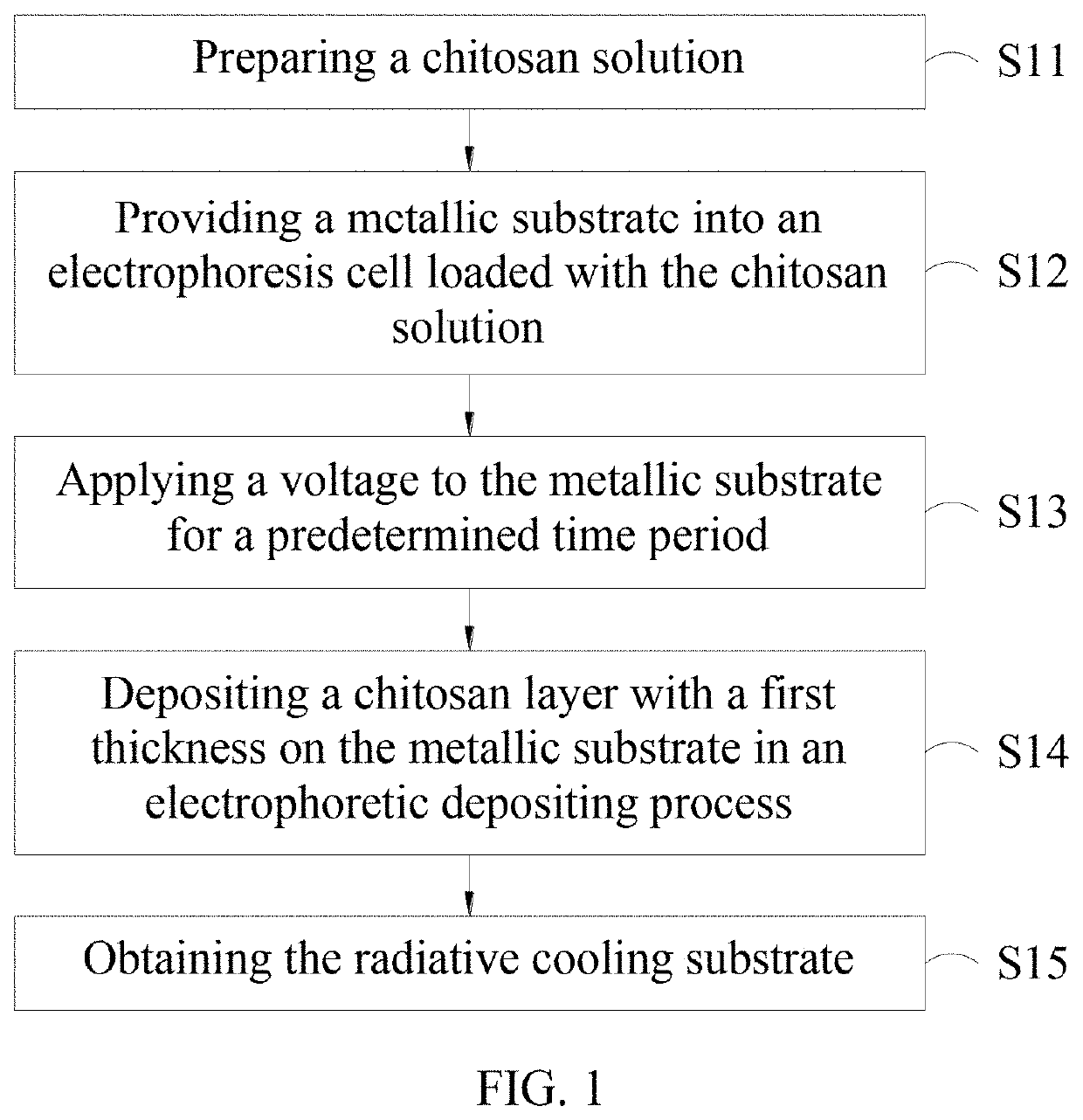

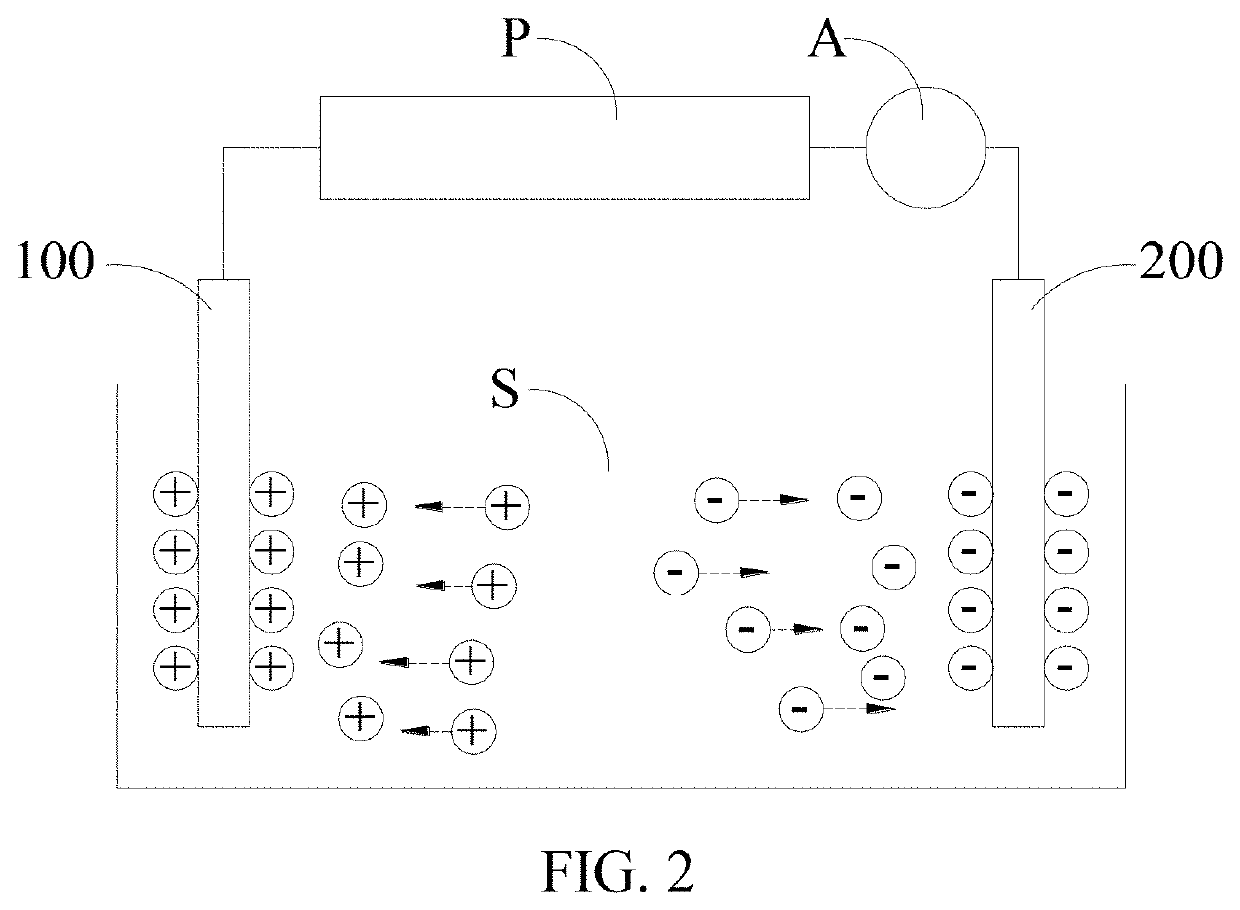

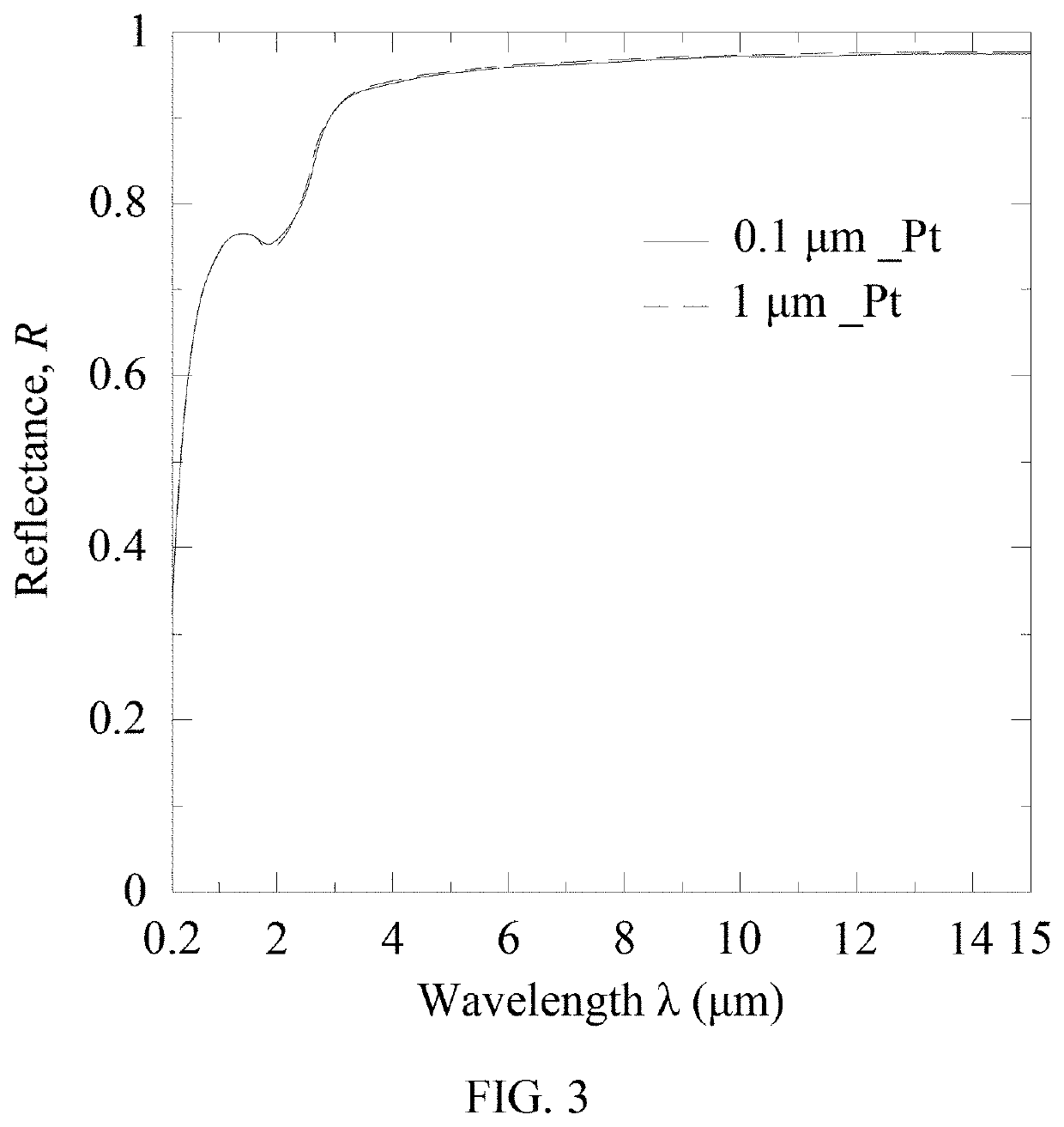

Radiative cooling substrate and manufacturing method of the same

ActiveUS11078593B2High emissivityLarge deposition areaElectrophoretic coatingsPaints for electrolytic applicationsPhysical chemistryWave band

Owner:NATIONAL TSING HUA UNIVERSITY

Biodegradable resin and method for manufacturing same

Provided is a biodegradable resin including a urethane bond generated by a reaction of a polyester polymer with a polyvalent isocyanate used as a chain extender. Particularly, provided is a method of preparing a biodegradable resin using a limited amount of the chain extender and having excellent properties, and a biodegradable resin in which nitrogen content is controlled. Therefore, the biodegradable resin which can reduce the use of a harmful component to the human body and environment in the process of preparing the biodegradable resin and can be safely used for packing materials for food or medicine is provided.

Owner:LOTTE FINE CHEM CO LTD +1

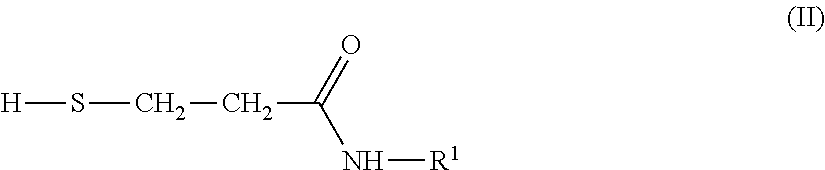

Preparation of n-substituted isothiazolinone derivatives

InactiveUS20110112327A1More cost-effectiveLess harmful to the environmentOrganic compound preparationCarboxylic acid amides preparationIsothiazolinoneManufacturing cost reduction

Owner:BEIJING TIANQING CHEM CO LTD

Preparation of N-substituted isothiazolinone derivatives

InactiveUS7893273B2More cost-effectiveLess harmful to the environmentOrganic compound preparationCarboxylic acid amides preparationIsothiazolinoneManufacturing cost reduction

Provided is a process for the preparation of an N-substituted isothiazolinone derivative having the general formula (I), comprising reacting N-substituted 3-mercaptopropionamides of formula (II) or N,N′-bis-substituted 3,3′-dithiodipropionamides of formula (III) with sulfuryl chloride in the absence of solvents. Also provided is a process for the preparation of a compound having the general formula (III), comprising reacting a methyl ester of formula (IV) with an amine of formula (V) in a solvent of methanol. As no addition solvent is used in the process of the invention, the cost of manufacturing and pollution to the environment can be reduced.

Owner:BEIJING TIANQING CHEM CO LTD

Mechanically advantaged band clamp and associated method

InactiveUS20060205285A1Easy to installEasy to removeElectric connection basesClamped/spring connectionsElectricityElectrical conductor

An electromechanical connector for use between a power source such as a battery and a device requiring the power such as an automotive electrical system. In some embodiments, the connector includes a radius electrical contact constituting a primary electrical current path, and a band clamp with a slotted band constituting a secondary current path, and a worm drive adjustment assembly for symmetrically tighten the connector to the battery post. A kit is described having an electrical-contact conductor with a concave surface conforming to a battery post, and a band clamp to symmetrically compress the conductor against the post. Some embodiments provide a conductor that conforms to an outer portion of the post, and includes a band clamp mechanism with a band fixed at a non-moving end to the conductor, and at an opposite slotted end interfacing to a worm screw held against the conductor.

Owner:MECHANICAL ANSWERS

Analgesic agent for newborn or fetal subjects

InactiveUS20060233885A1Total current dropFast induction and emergenceBiocideNervous disorderObstetricsAnalgesic agents

In a first aspect, the present invention relates to the use of xenon in the preparation of a medicament for providing analgesia in a newborn subject and / or a fetal subject. In a second aspect, the invention relates to a method of providing analgesia in a newborn subject, the method comprising administering to the subject a therapeutically effective amount of xenon. In a third aspect, the invention relates to a method of providing analgesia in a fetal subject, the method comprising administering to the mother of the fetal subject a therapeutically effective amount of xenon for both the mother and fetal subject.

Owner:IP2IPO INNOVATIONS LTD

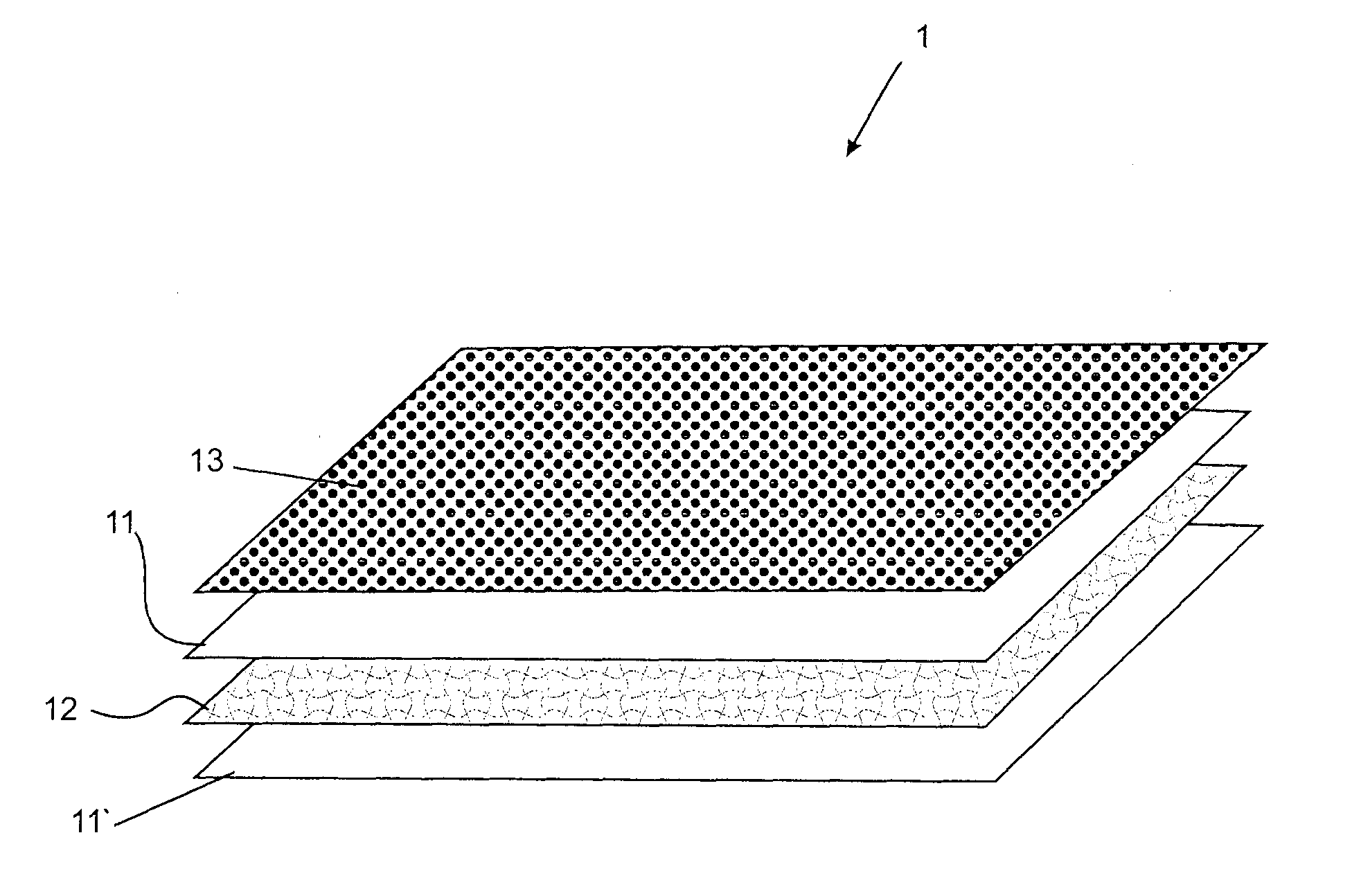

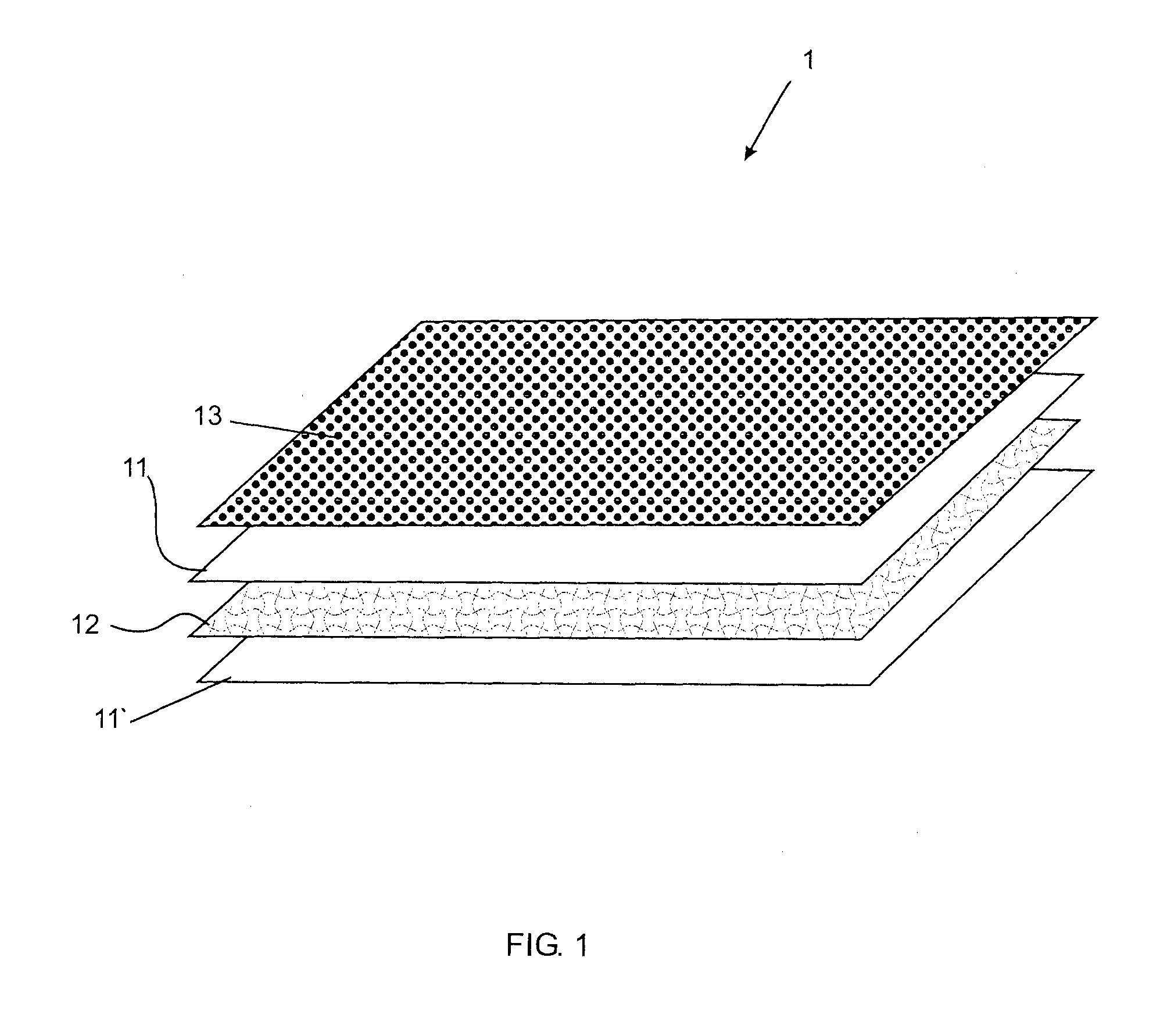

A process for manufacturing a composite material, and a composite material shaped with layers

InactiveUS20160193804A1Reduce processing timeLow production costSynthetic resin layered productsCellulosic plastic layered productsInter layerSynthetic fiber

A description is given of a new product composed of natural and synthetic fibres, and also processes for producing a material for structural use that consists in the following steps: (i) arranging at least a first blanket 11 and at least a second blanket 11′, each of which is composed of natural and synthetic fibres and of at least one intermediate layer 12 based on olefins, between the first blanket 11 and the second blanket 11′, in order to obtain the required geometry; (ii) heating, compression and adhesion of the assembly obtained in step (i); and (iii) cooling of the assembly obtained in step (ii) to at least a hardening temperature.

Owner:RICCIARDI JOSE CARLOS

Method for preparing trioxane

ActiveUS9994544B2Less harmful to the environmentSimple and reliable and economicalOrganic chemistry1,3,5-TrioxaneTrioxane

The present invention concerns a method for preparing 1,3,5-trioxane by trimerization of formaldehyde in the presence of methanesulfonic acid. The invention also concerns the use of at least one catalyst comprising methanesulfonic acid for the trimerization of formaldehyde into 1,3,5-trioxane.

Owner:ARKEMA FRANCE SA

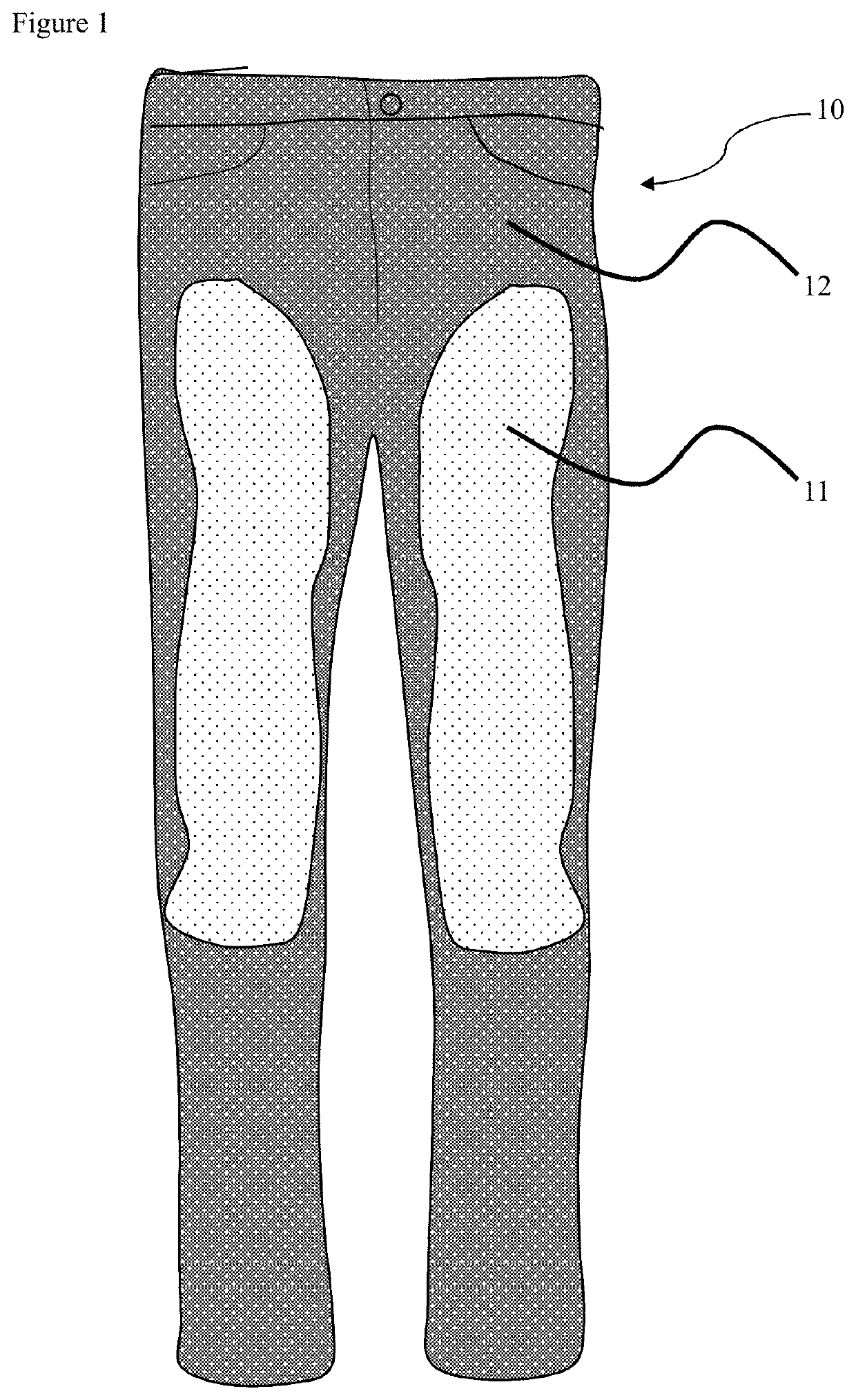

Method for changing the colour of a textile, fabric and garment

PendingUS20200354889A1Good fade effectLess harmful to the environmentDyeing processPolymer scienceEngineering

The invention refers to a fabric finishing method suitable for changing the colour of a coloured fabric thereby providing a vintage look to the fabric. The invention refers also to the fabric obtainable by the above method and to a garment comprising such fabric.

Owner:SANKO TEKSTIL ISLETMELERI SANAYI & TICARET A S

Polymer catalytic membrane containing palladium metal active functional layer and preparation method thereof

InactiveCN102512991BEasy to prepareNo need for external power conditionsSemi-permeable membranesOrganic compound preparationPotassium borohydridePotassium

The invention relates to a polymer catalytic membrane containing a palladium metal activity functional layer prepared based on the technology of layer-by-layer self assembly and a preparation method thereof, which belongs to the field of catalytic membranes. According to the invention, polyacrylonitrile (PAN) powder, polyethylene glycol (PEG) and polyvinylpyrrolidone (PVP) are dissolved in N,N-dimethyl formamide (DMF), and a PAN flat base membrane is prepared by using a phase inversion process; then the PAN membrane is soaked in a NaOH solution for treatment, which allows surface of the membrane to hydrolyze so as to produce carboxyl groups, thereby enabling the surface of the membrane to carry negative electric charges; a polyethyleneimine (PEI) solution and a potassium chloropalladate K2PdCl4 solution are fully mixed and react for a certain period of time so as to obtain a coordination compound of polyethyleneimine-palladium (PEI-Pd(II)); the treated flat base membrane is alternatively soaked in a solution containing the PEI-Pd(II) coordination compound and a polystyrene sulfonate (PSS) solution for self-assembly of functional layers on the surface of the membrane, and the amount of the assembled layers is controlled; and finally, the membrane obtained after assembly is soaked in a potassium borohydride KBH4 solution, Pd(II) is reduced to be Pd0, and the PAN catalytic membrane containing the palladium metal particle active layer is prepared.

Owner:TIANJIN POLYTECHNIC UNIV

A fluorescent probe for detecting silver ions and its preparation method and application

ActiveCN107973785BGood choiceImprove featuresOrganic chemistryFluorescence/phosphorescenceLinear correlationFluorescence

The invention discloses a fluorescence probe for detecting a silver ion, and provides a preparation method and application thereof at the same time. The fluorescence probe can quickly respond and high-selectively detect the silver ion. The fluorescence probe for detecting the silver ion provided by the invention has a structure as shown in a formula 1. The probe provided by the invention can selectively react with the silver ion so as to produce fluorescence-emission red shift. The reaction is not interfered by other metal ions, a fluorescence-emission peak change can be produced within a short time, and the wave length of the fluorescence-emission peak red shift is in linear correlation with the concentration of the silver ion. The fluorescence probe provided by the invention only carriesout fluorescence reaction with the silver ion instead of other metal ions, so that the fluorescence probe has better selectivity and specificity.

Owner:浙江工业大学上虞研究院有限公司

Recycling method of spent lithium-ion battery cathode materials based on mechanochemical method

ActiveCN110791652BEfficient leachingHazard reductionSolid waste disposalWaste accumulators reclaimingMetallic lithiumElectrical battery

Owner:HUAZHONG UNIV OF SCI & TECH

Ceramic circuit cyanide-free copper plating solution, preparation method and electroplating process

The invention discloses a ceramic circuit cyanide-free copper plating solution, a preparation method and an electroplating process. The cyanide-free copper plating solution mainly includes 15-20 g / L of copper chloride, 30-50 g / L of basic copper carbonate, 5-8 g / L of sodium ethylenediamine teramethylene phosphonate, 18-25 g / L of seignette salt, 280-320 g / L of citric acid, 15-18 g / L of sodium bicarbonate, 0.02-0.03 g / L of selenium dioxide and an appropriate amount of potassium hydroxide. The ceramic circuit cyanide-free copper plating solution can be used for cyanide-free copper plating, is green and environment-friendly, cheap in selected raw material and low in preparation cost; and the copper plating layer obtained by plating on a ceramic circuit substrate through the copper plating formula solution is meticulous, uniform, low in porosity and good in binding force.

Owner:CETC GUOJI SOUTHERN GRP CO LTD

Radiative cooling substrate and manufacturing method of the same

ActiveUS20200131660A1Dissipate thermal energyCommercial value of wasteElectrophoretic coatingsPaints for electrolytic applicationsPhysical chemistryWave band

A radiative cooling substrate and a manufacturing method of the radiative cooling substrate are provided. The radiative cooling substrate includes a metallic substrate and a chitosan layer disposed on the metallic substrate with a thickness of 0.5 μm to 10 μm. The chitosan layer emits radiation within a waveband between 8 μm and 13 μm.

Owner:NATIONAL TSING HUA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com