Recovery method for waste lithium ion battery anode materials based on mechano-chemical method

A technology of lithium-ion battery and mechanochemical method, which is applied in the field of recycling waste lithium-ion battery positive electrode materials, can solve the problems of high cost, great environmental hazards of waste liquid, and low recovery rate, and achieve low cost, low environmental hazard, High economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

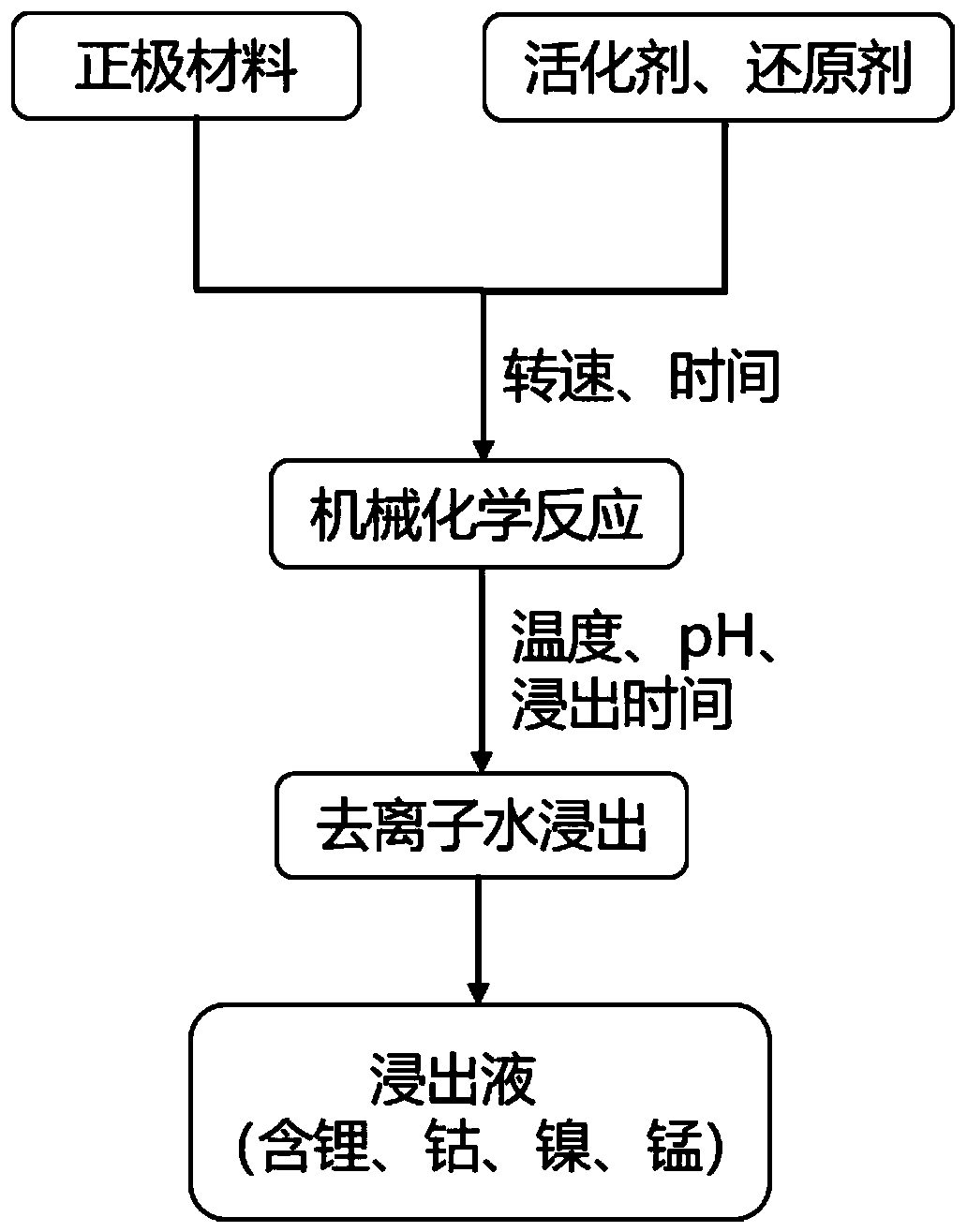

[0029] A flexible leaching method for valuable metals in waste lithium-ion battery cathode materials based on mechanochemical method, figure 1 The present invention is a process flow diagram for leaching valuable metal elements such as lithium, cobalt, nickel, manganese from waste lithium ion battery positive electrode materials, comprising the following steps:

[0030] (1) Put 0.5 g of pretreated waste lithium-ion battery ternary positive electrode material, 1.0 g of potassium persulfate, 0.5 g of glucose and 80 g of zirconia grinding balls into a zirconia ball milling tank, and ball mill for 3 hours at a speed of 800 rpm.

[0031] (2) Transfer the mixed material after ball milling to 100mL deionized water and stir evenly, adjust the pH of the system to 2.0, stir magnetically at 50°C for 40min, cool to room temperature, and filter to obtain a leachate containing lithium, cobalt, nickel, and manganese .

[0032]It has been determined that the leaching rates of lithium, cobalt...

Embodiment 2

[0034] A flexible leaching method for valuable metals in waste lithium-ion battery cathode materials based on mechanochemical method, figure 1 The present invention is a process flow diagram for leaching valuable metal elements such as lithium, cobalt, nickel, manganese from waste lithium ion battery positive electrode materials, comprising the following steps:

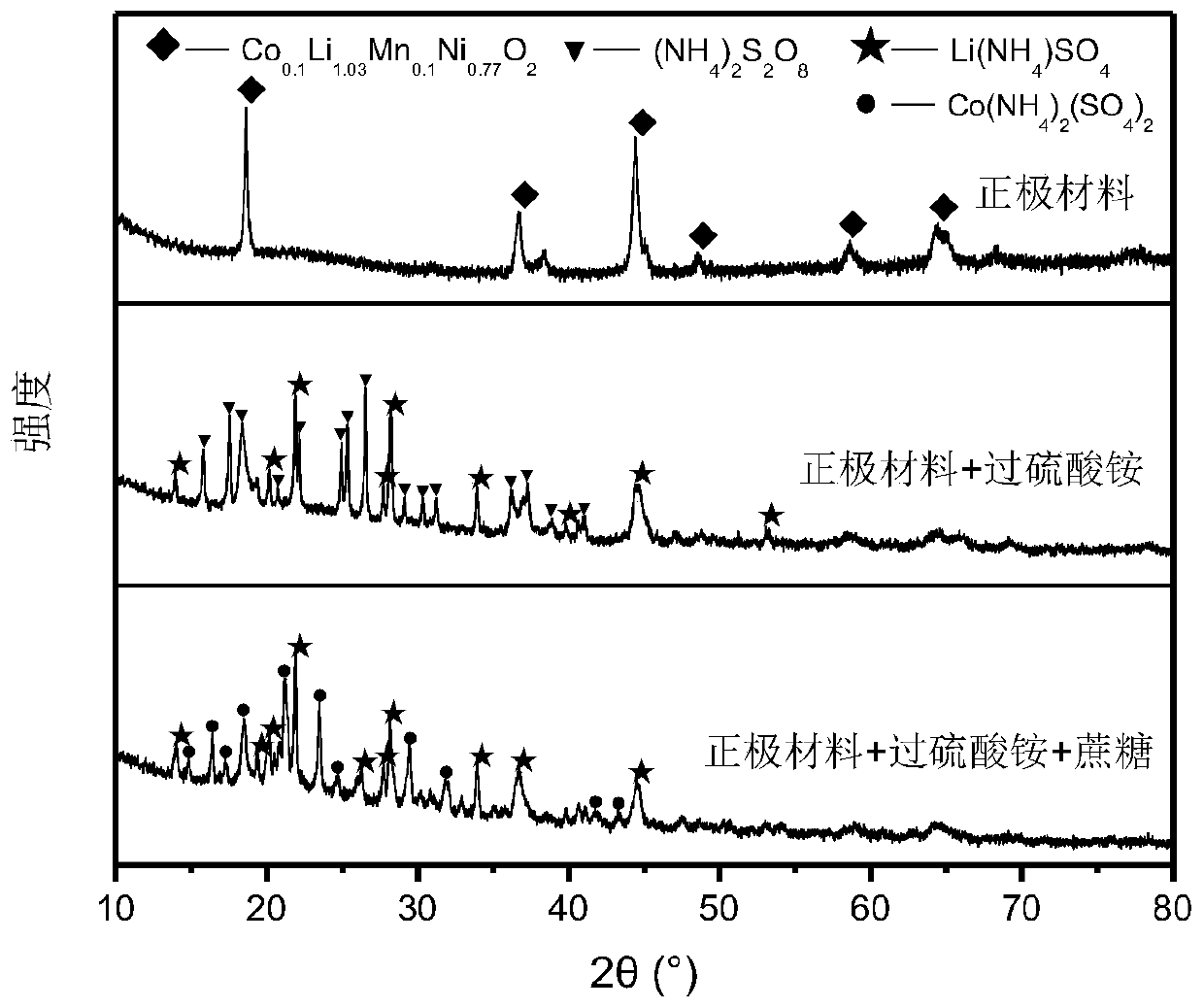

[0035] (1) Put 0.4g of the pretreated waste lithium-ion battery positive electrode material, 1.2g of ammonium persulfate, 0.4g of sucrose and 60g of zirconia grinding balls into a zirconia ball mill jar, and ball mill for 2 hours at a speed of 1000rpm.

[0036] (2) Transfer the mixed material after ball milling to 100mL deionized water and stir evenly, adjust the pH of the system to 2.0, stir magnetically at 60°C for 30min, cool to room temperature, and filter to obtain a leachate containing lithium, cobalt, nickel, and manganese .

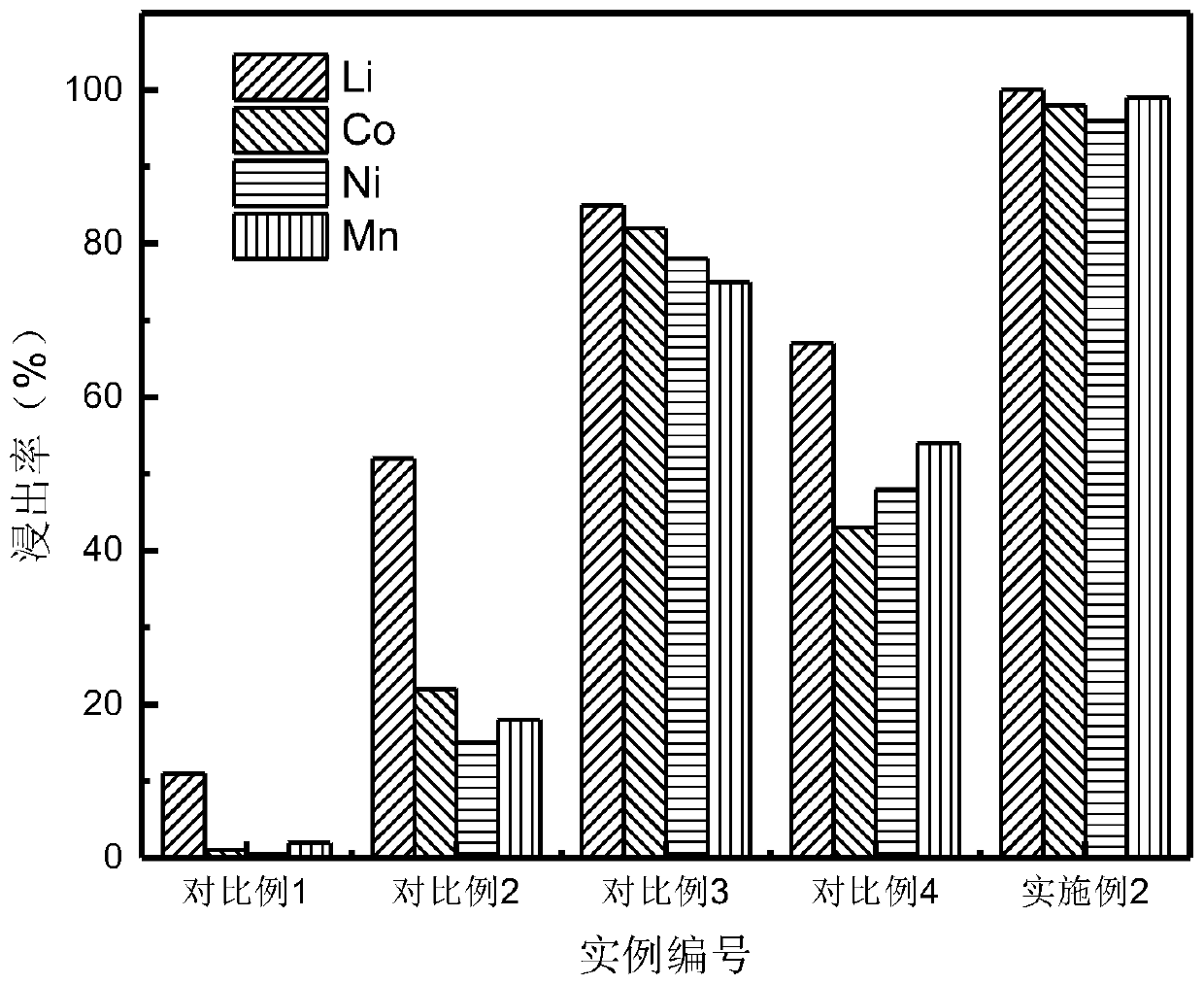

[0037] It has been determined that the leaching rates of lithium, cobalt, nickel, an...

Embodiment 3

[0039] A flexible leaching method for valuable metals in waste lithium-ion battery cathode materials based on mechanochemical method, figure 1 The present invention is a process flow diagram for leaching valuable metal elements such as lithium, cobalt, nickel, manganese from waste lithium ion battery positive electrode materials, comprising the following steps:

[0040] (1) Put 0.4g of the pretreated waste lithium-ion battery positive electrode material, 1.0g of ammonium persulfate, 0.6g of sucrose and 200g of zirconia grinding balls into a zirconia ball mill jar, and ball mill for 10 hours at a speed of 100rpm.

[0041] (2) Transfer the mixed material after ball milling to 100mL deionized water and stir evenly, adjust the pH of the system to 2.0, stir magnetically at 60°C for 30min, cool to room temperature, and filter to obtain a leachate containing lithium, cobalt, nickel, and manganese .

[0042] It has been determined that the leaching rates of lithium, cobalt, nickel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com