Carbon dioxide fracturing fluid and preparation method thereof

A technology of carbon dioxide and fracturing fluid, which is applied in the direction of chemical instruments and methods, bulk chemical production, drilling compositions, etc., can solve the problems of fracture creation and sand-carrying capacity reduction, so as to reduce the viscosity of crude oil and benefit the environment Protective, promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of liquid carbon dioxide fracturing fluid: Take the high-temperature and high-pressure closed system of MARSⅡ rheometer of HAAKE company, add 0.1wt% thickener polycarbonate-chlorostyrene copolymer and 0.01wt% multi-effect additive perfluorinated to it Sodium alkylbenzene sulfonate is loaded into the inner rotor and inner magnetic steel, the upper cover is installed, and the inner hexagonal bolts are tightened to seal the high-temperature and high-pressure closed system. Using a carbon dioxide steel cylinder, press 99.89wt% liquid carbon dioxide into the high-temperature, high-pressure closed system through the injection valve, set the instrument to rotate the inner rotor, and speed up the dissolution of the thickener and multi-effect additive. The pressure is increased to keep the carbon dioxide in a liquid state in the closed system. After setting the instrument to stir at room temperature for 30 minutes, the thickener and multi-effect additives are dissolv...

Embodiment 2

[0024] Preparation of liquid carbon dioxide fracturing fluid: In Example 1, change "add 0.1wt% thickener polycarbonate-chlorostyrene copolymer and 0.01wt% multi-effect additive sodium perfluoroalkylbenzene sulfonate" to " Add 0.5wt% thickener polycarbonate-methylstyrene copolymer and multi-effect additive sodium perfluoroalkylbenzene sulfonate 0.1wt% and sodium perfluorooctane sulfonate 0.1wt%, correspondingly press the Enter 99.89wt% liquid carbon dioxide " into " press into 99.3wt% liquid carbon dioxide ", all the other steps are with embodiment 1.

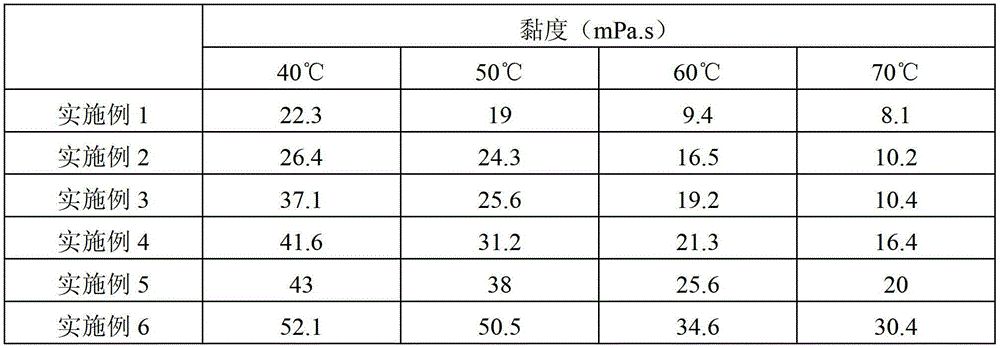

[0025] The methods for testing the viscosity of liquid carbon dioxide fracturing fluid in Examples 2-6 are the same as those in Example 1. The test results are shown in Table 1.

Embodiment 3

[0027] Preparation of liquid carbon dioxide fracturing fluid: In Example 1, change "add 0.1wt% thickener polycarbonate-chlorostyrene copolymer and 0.01wt% multi-effect additive sodium perfluoroalkylbenzene sulfonate" to " Add 1.0wt% thickener polycarbonate-chlorostyrene copolymer and 0.3wt% multi-effect additive sodium perfluorooctane sulfonate", and correspondingly change "press into 99.89wt% liquid carbon dioxide" to "press Enter 98.7wt% liquid carbon dioxide ", all the other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical point | aaaaa | aaaaa |

| triple point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com