Temporary plugging and fracturing process in degradable fiber clearance

A technology of degrading fiber and fracturing, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of expanding oil well drainage area and poor effect, so as to increase single well production and expand drainage area , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

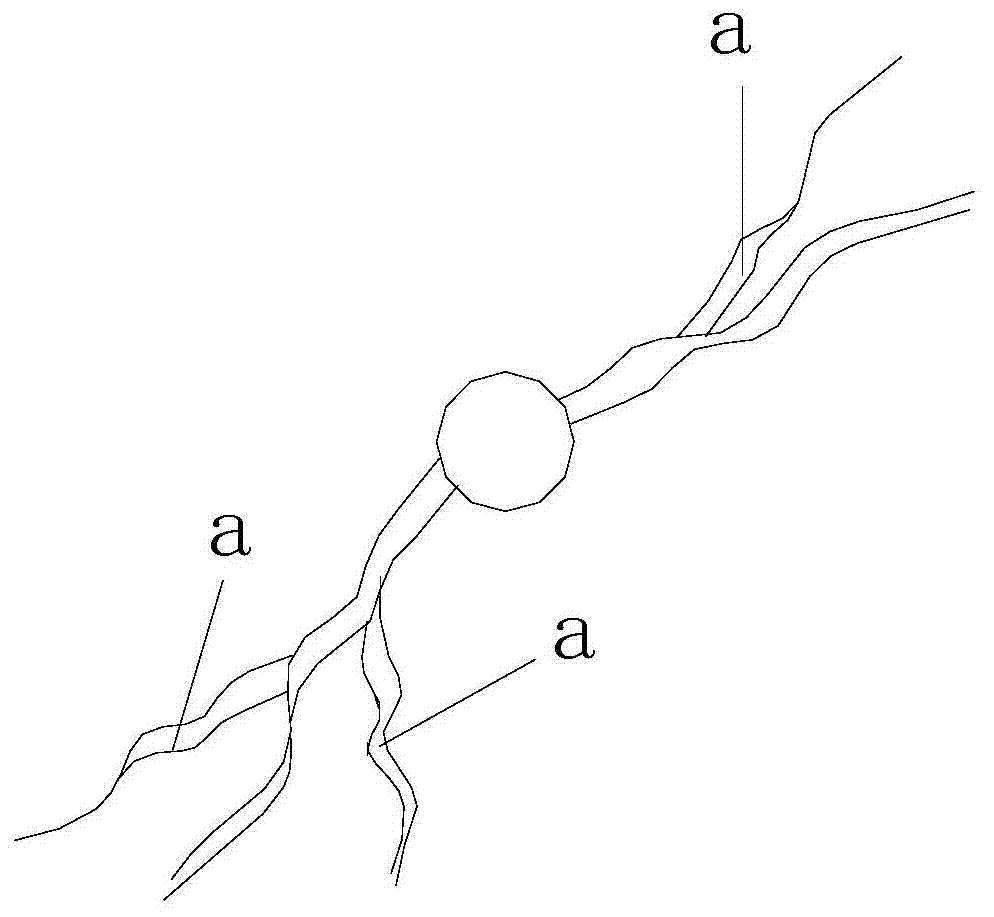

[0017] The present invention optimizes the amount of degradable fiber and the construction displacement according to the properties of the reservoir, the working fluid, and the concentration of sand, and injects the construction working fluid prepared by the ground sand mixing equipment during the fracturing construction. The working fluid is composed of degradable fiber Composed of polyester fiber (1.0%-2.0%) + linear glue (0.45%) + proppant (20%-35%) and aqueous solution, the above-mentioned degradable polyester fiber is produced by Daqing Hengrun Petroleum Technology Development Co., Ltd., available in 70 Under the experimental temperature of ℃, the degradation rate reached 98% in 2 hours, and the linear adhesive viscosity was increased by 45%. At the same time, the fibers interacted with the proppant particles in the fracturing fluid to form a network structure, preventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com