On-line hob cutter abrasion detection method for boring machine

A detection method, technology of roadheader, applied in the direction of testing wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

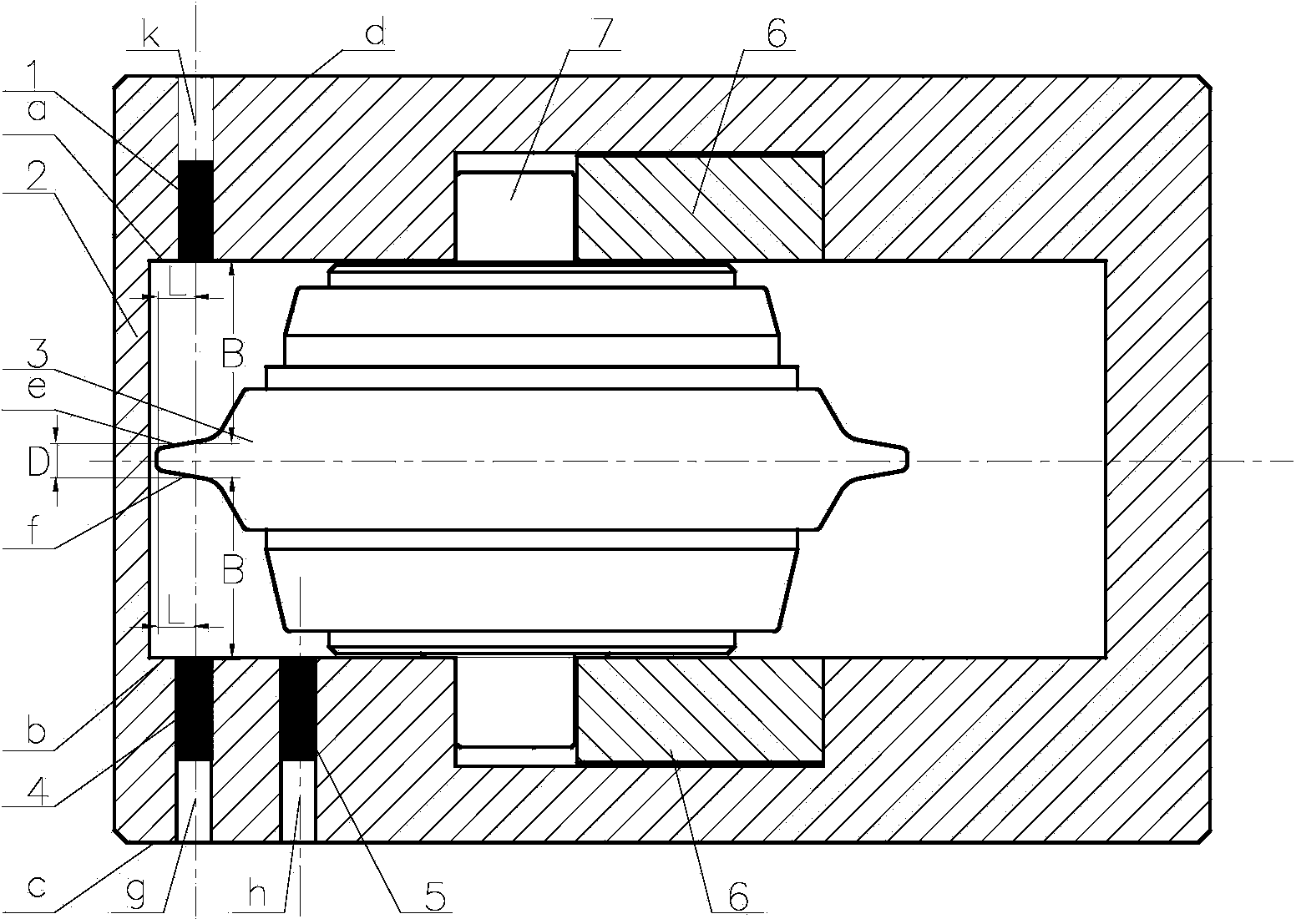

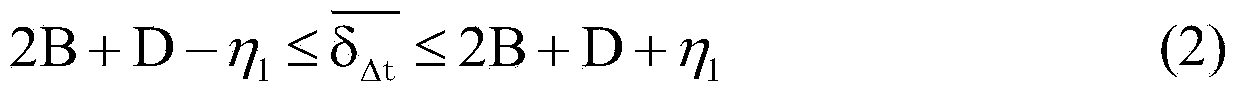

[0040] The specific implementation of the present invention will be described in detail below with reference to the drawings and technical solutions. The hob is the most consumed consumable during the use of the roadheader. The hob of the roadheader is divided into normal wear, chord eccentric wear, blade eccentric wear, cutter ring fracture and cutter ring displacement according to the wear condition during operation. The characteristic of normal wear is that the degree of wear of the surrounding parts of the hob cutter ring is basically the same, which is the main form of tool failure, which mainly occurs in relatively simple and uniform geological formations; both chord and edge wear are rolling The eccentric wear of the knife is caused by the inconsistent degree of wear of the various parts around the hob ring. There are three types of chord eccentric wear, unilateral eccentric wear, multilateral eccentric wear, and bearing wear. Unilateral eccentric wear means that the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com