Settling, isolating and removing integrated dust prevention method of fully mechanized excavation face

A technology for working face and fully mechanized excavation, which is applied in the field of integrated dust prevention, fully mechanized excavation working face lowering, and separation. It can solve the problems of poor respirable dust capture ability, electrical safety hazards, gas and coal dust explosion accidents, etc., to achieve Improve the effect of governance, improve the effect of dust suppression, and the effect of efficient suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

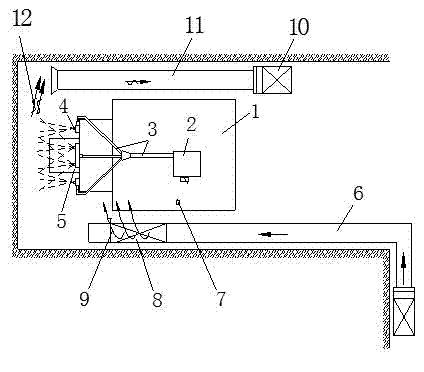

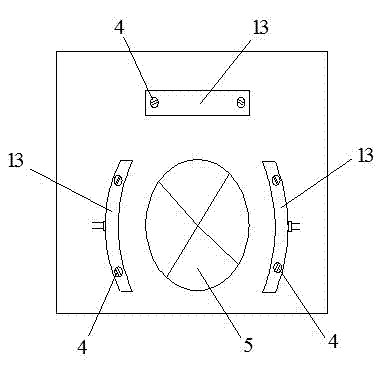

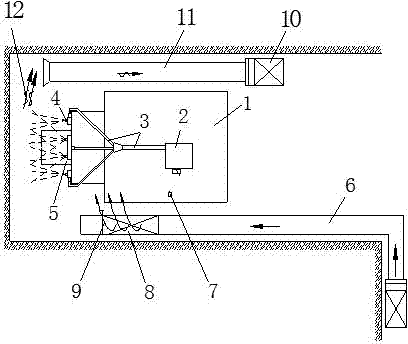

[0019] As shown in the accompanying drawings, the present invention fixes the foam generator 2 on the platform of the fully-mechanized excavator machine body 1 next to the fully-mechanized excavator driver's seat 7, arranges the spray head frame 13 around the fully-mechanized excavator cutting part 5, and puts a spray head on each spray head. Two foam nozzles 4 are installed on the frame, the foam nozzles 4 are connected with the foam generator 2 through the high-pressure rubber hose 3, and a press-in air cylinder 6 is arranged on the side of the roadway, and the front end of the press-in air cylinder 6 is arranged with a wall-attached air cylinder 8. The outlet of the press-in air cylinder 6 is 14m away from the head of the excavation. The air outlet of the wall-attached air cylinder 8 is located 1.2m in front of the driver's seat 7 of the comprehensive exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com