Pipe jacking construction structure and pipe jacking construction method

A construction method and pipe jacking technology, which is applied in the direction of pipes/pipe joints/fittings, earthwork drilling, pipe laying and maintenance, etc. It can solve problems such as difficulties in laying down pipes, difficulty in taking out slings, and increased costs, so as to prevent pipe surface damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

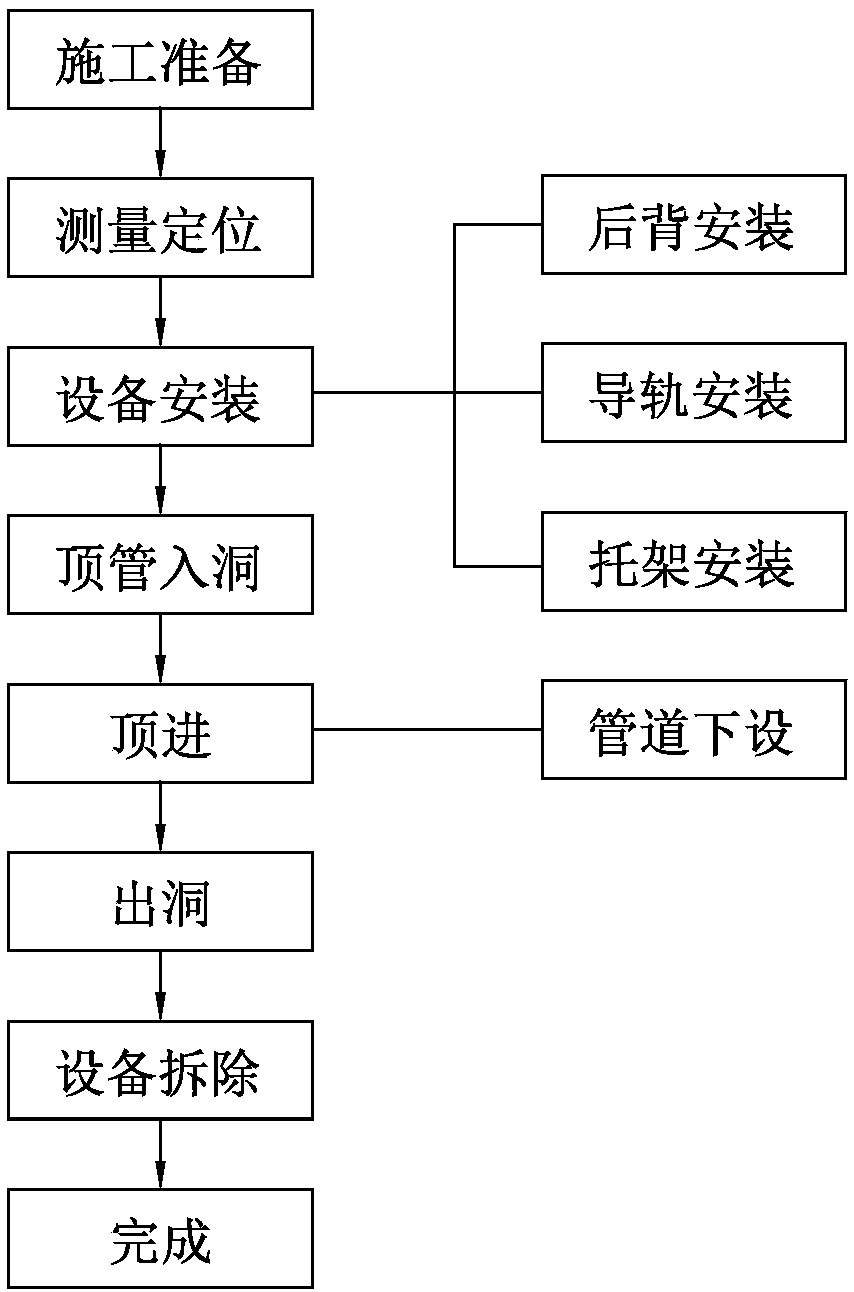

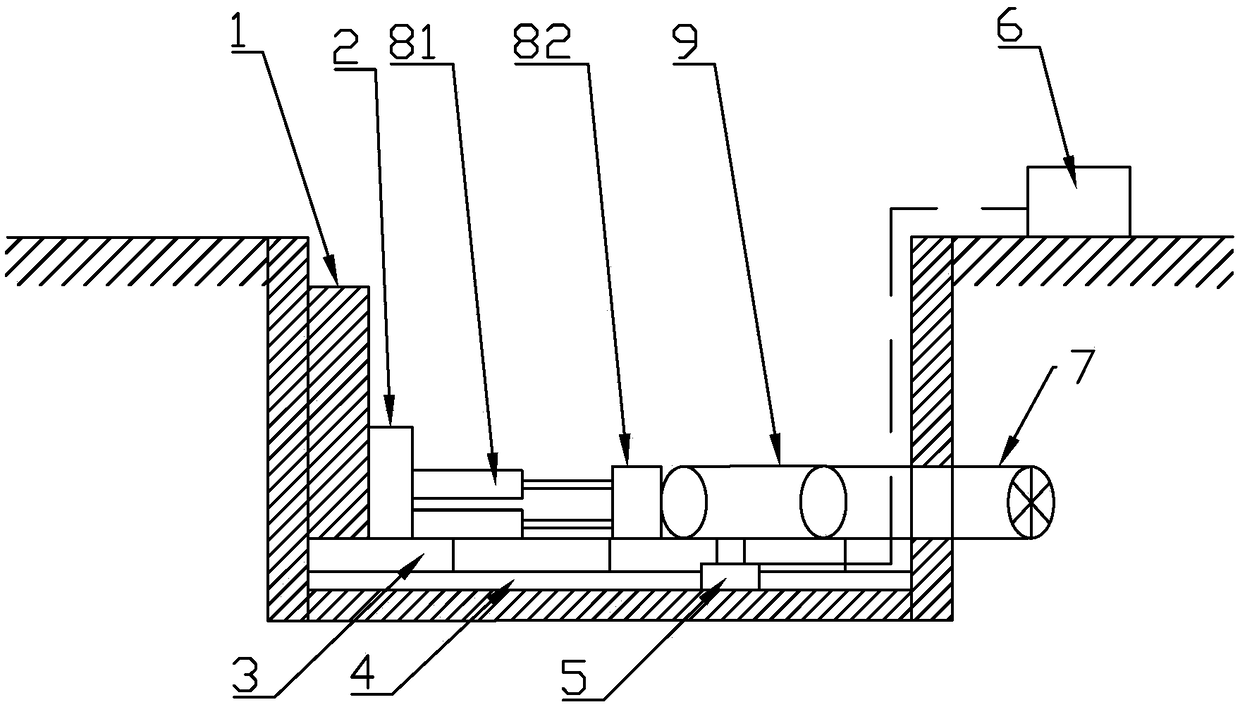

[0048] Such as figure 1 , image 3 , Figure 4 As shown, the pipe jacking construction method provided by the present invention includes the following steps: construction preparation, measurement and positioning, equipment installation (also including the installation of guide rails, backs and hydraulic brackets), pipe jacking into the hole, jacking (under the pipeline) ), excavation, equipment dismantling until completion, of which:

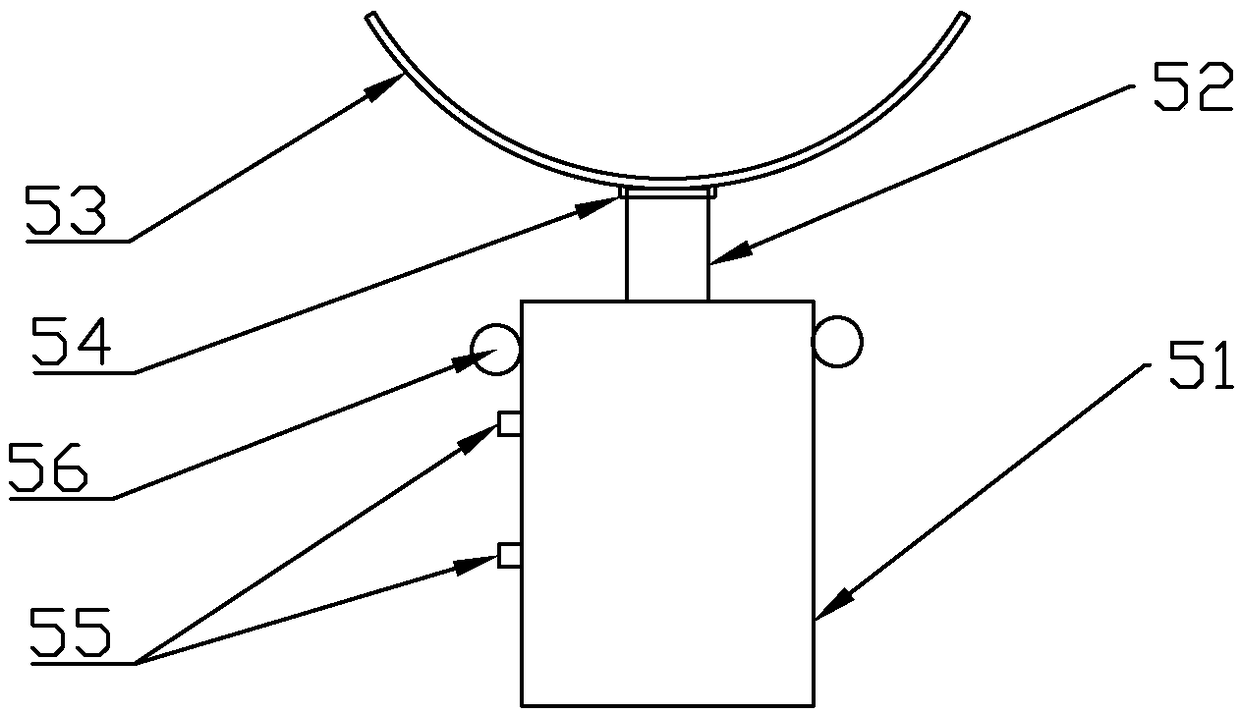

[0049] 1) construction preparation, in addition to routine preparation work (comprising foundation pit forming), the present invention mainly is to prepare hydraulic jack bracket 5, as figure 2 As shown, the hydraulic jack bracket 5 mainly includes a hydraulic cylinder 51, a piston rod 52, and a steel bracket 53 fixed at the end of the piston rod 52. One side of the steel bracket 53 has a circular arc that fits the arc of the outer wall of the pipeline. On the other side, the other side is connected with the piston rod 52 through the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com