Catalyst for preparing olefins from synthesis gas and preparation method thereof

A catalyst, a technology for producing olefins, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. chance of secondary reaction, effect of avoiding selective influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

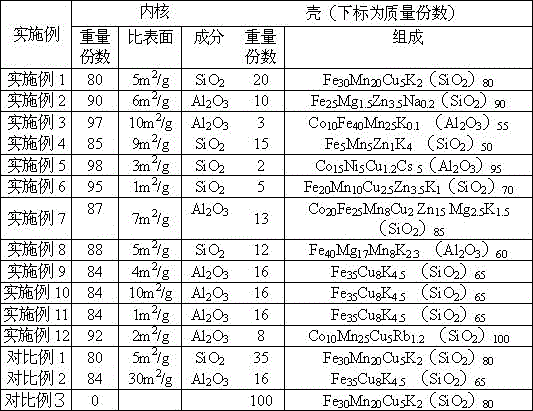

Examples

Embodiment 1

[0023]Dissolve 23.44g of ferric nitrate hexahydrate, 0.36g of potassium hydroxide, 16.27g of manganese nitrate solution with a mass concentration of 50% and 2.37g of copper nitrate trihydrate in water to form a solution. Add 25g of silica sol with a concentration of 40% to prepare a slurry.

[0024] Take by weighing 80g silica core (specific surface area is 5m 2 / g), the above slurry was sprayed onto the silica inner core, baked at 120°C for 6 hours, and then fired at 600°C for 2 hours to obtain the catalyst 20Fe 30 mn 20 Cu 5 K 2 (SiO 2 ) 80 -80 (SiO 2 ), the numbers outside the brackets are parts by weight.

Embodiment 2

[0026] Dissolve 11.27g of ferric nitrate hexahydrate, 0.03g of sodium hydroxide, 1.14g of magnesium nitrate hexahydrate and 1.14g of zinc nitrate hexahydrate in water to form a solution. Add 16.17g concentration of 40% silica sol to prepare slurry.

[0027] Take by weighing 90g alumina inner core (the specific surface area is 6m 2 / g), the above slurry was sprayed onto the alumina inner core, baked at 110°C for 8 hours, and then fired at 700°C for 8 hours to obtain the catalyst 10Fe 25 Mg 1.5 Zn 3.5 Na 0.2 (SiO 2 ) 90 -90 (Al 2 o 3 ) Numbers outside brackets are parts by weight.

Embodiment 3

[0029] Dissolve 4.63g of ferric nitrate hexahydrate, 0.003g of potassium hydroxide, 3.01g of manganese nitrate solution with a mass concentration of 50% and 1.11g of cobalt nitrate hexahydrate in water to form a solution. Add 3.39g of aluminum sol with a concentration of 30% to prepare a slurry.

[0030] Take by weighing 97g alumina core (specific surface area is 10m 2 / g), the above slurry was sprayed onto the alumina inner core, baked at 80°C for 12 hours, and then fired at 400°C for 6 hours to obtain the catalyst 3Co 10 Fe 40 mn 25 K 0.1 (Al 2 o 3 ) 55 -97 (Al 2 o 3 ), the numbers outside the brackets are parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com