Tunneling, anchoring and drilling composite machine

The technology of compound machine and drilling machine is applied in the fields of bolt-digging compound machine, drilling machine integrated new model, bolting machine and roadheader, which can solve the problems of low work efficiency, limitation of empty head distance, complicated hydraulic system, etc. , to achieve the effect of improving work efficiency, reducing space size, and simplifying design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

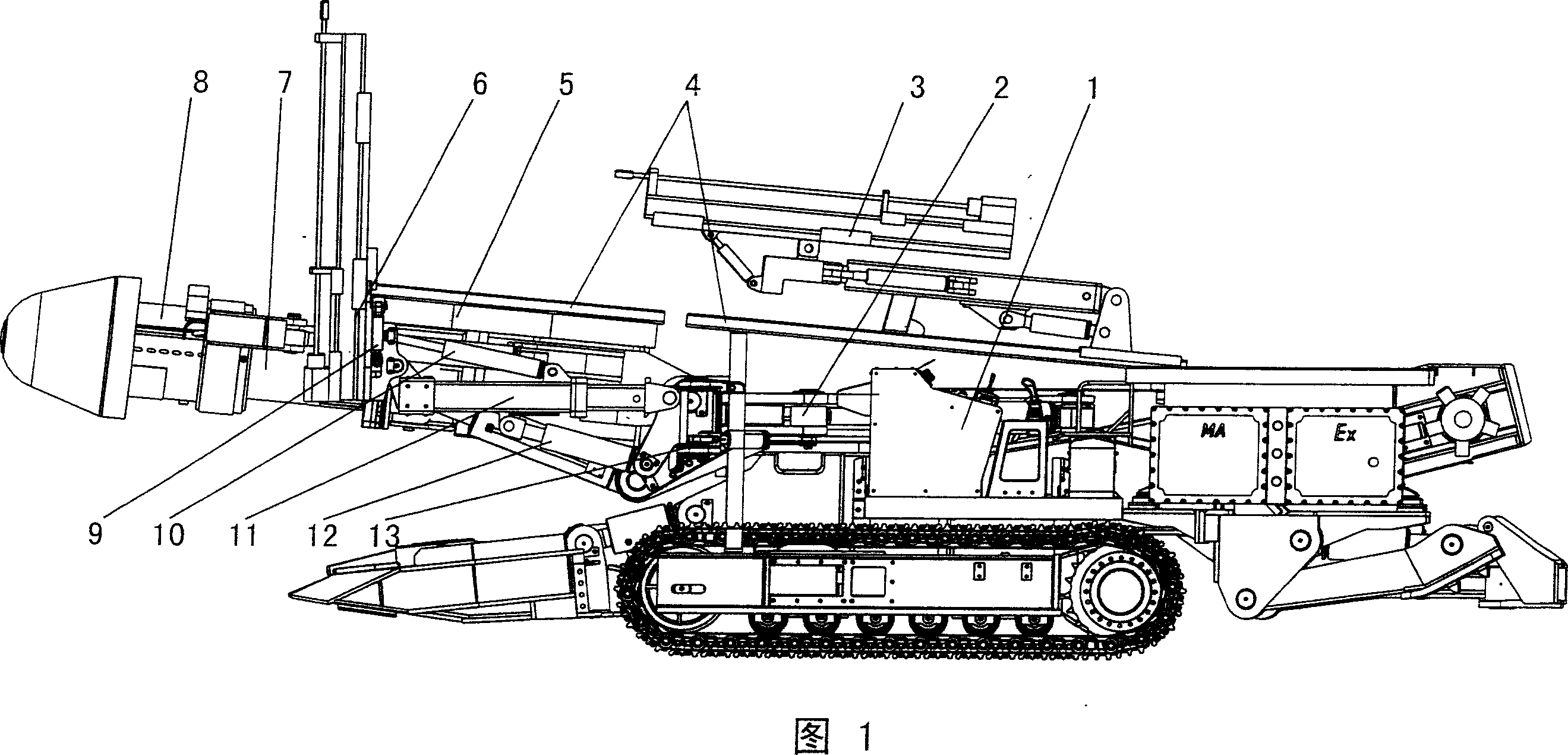

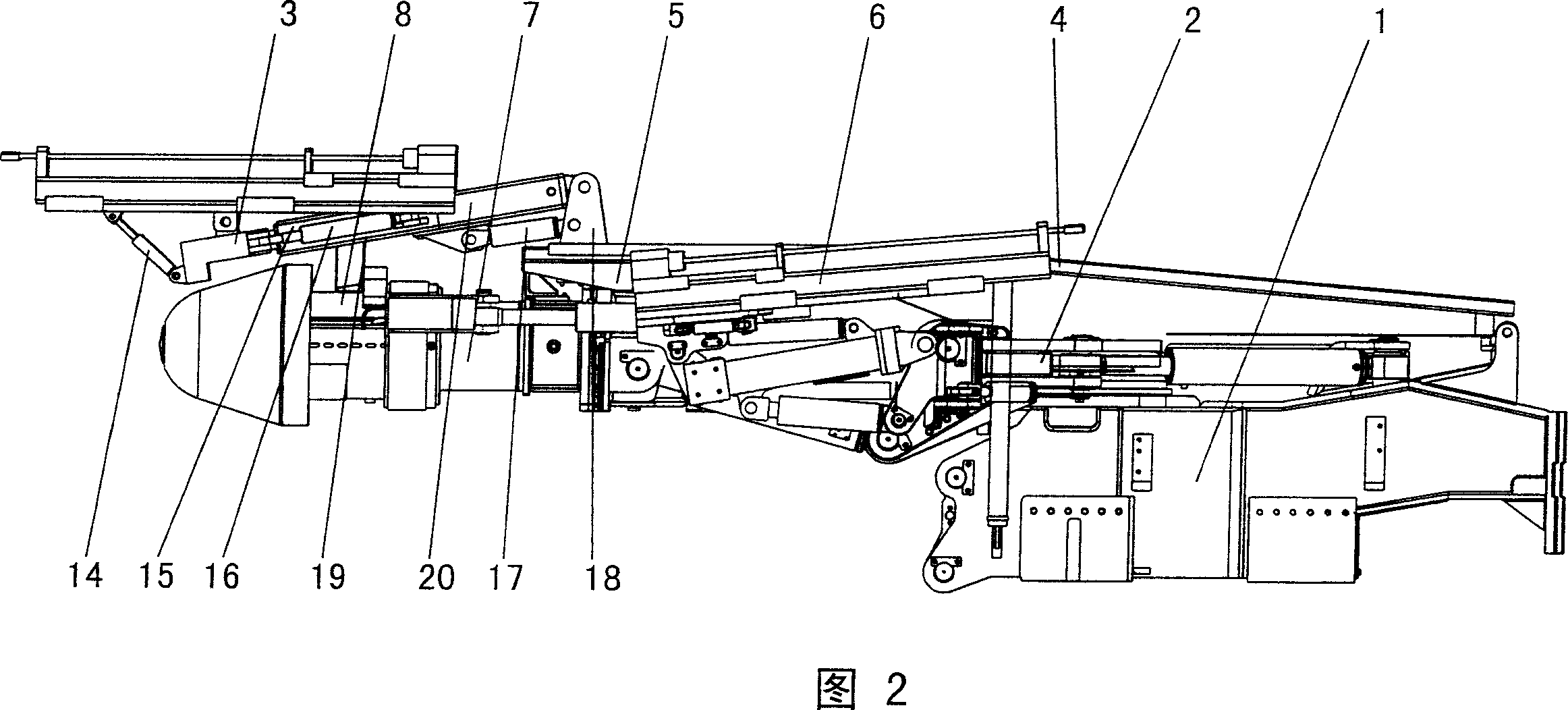

[0042] As shown in Figures 1-2, the present invention is a combined machine for digging, bolting and drilling, and the three machines of the roadheader, bolter and drilling machine are installed in one. The drilling machine 3 is installed on the upper part of the heading machine 1, and the drilling machine 3 and the heading machine 1 are connected by a track 4. The part above the tunneling machine 1 in the figure is the drilling machine 3 device. Together with the cutting part 7 of the roadheader 1, it can perform lifting and swinging motions, coupled with its own rotation and other functions, to complete the deep hole drilling of the roadway; the bolter 6 is symmetrically installed on the sidewall of the roadheader turret 2 , The bolter 6 and the boring machine turntable 2 are hinged by a hydraulic cylinder. In the figure, the oil cylinders on both sides of the front and their supporting parts are the bolter 6 device, which together with the cutting part 7 of the roadheader 1 swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com