Immediate support device for digging machine

A technology of supporting device and fully mechanized excavator, which is applied to mine roof supports, mining equipment, earth-moving drilling and other directions, can solve the problems of backward supporting means, need to stop operation, difficult to move the frame, etc., and achieves convenient loading and unloading and maintenance. Avoid distortion and out-of-sync, support the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

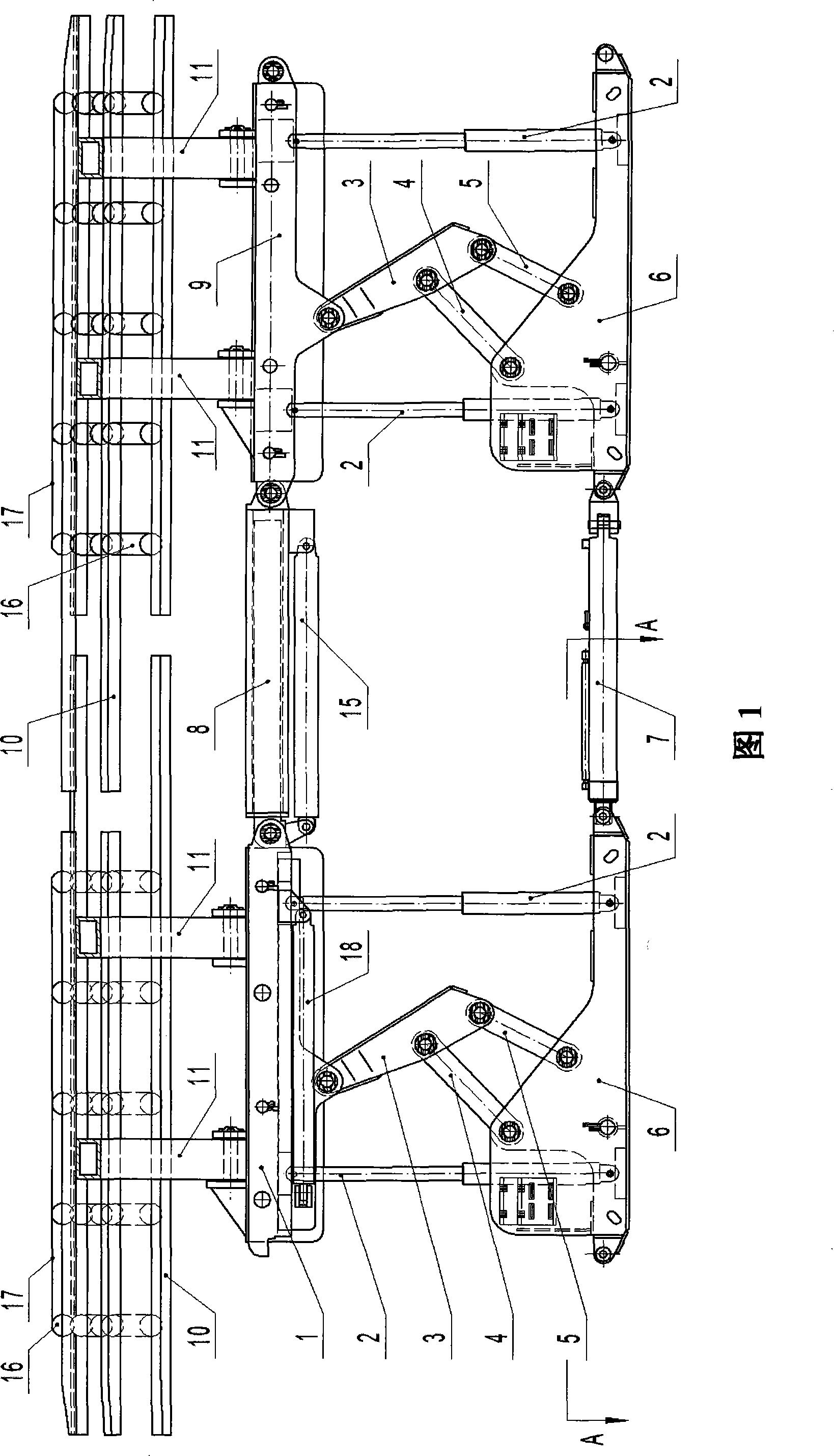

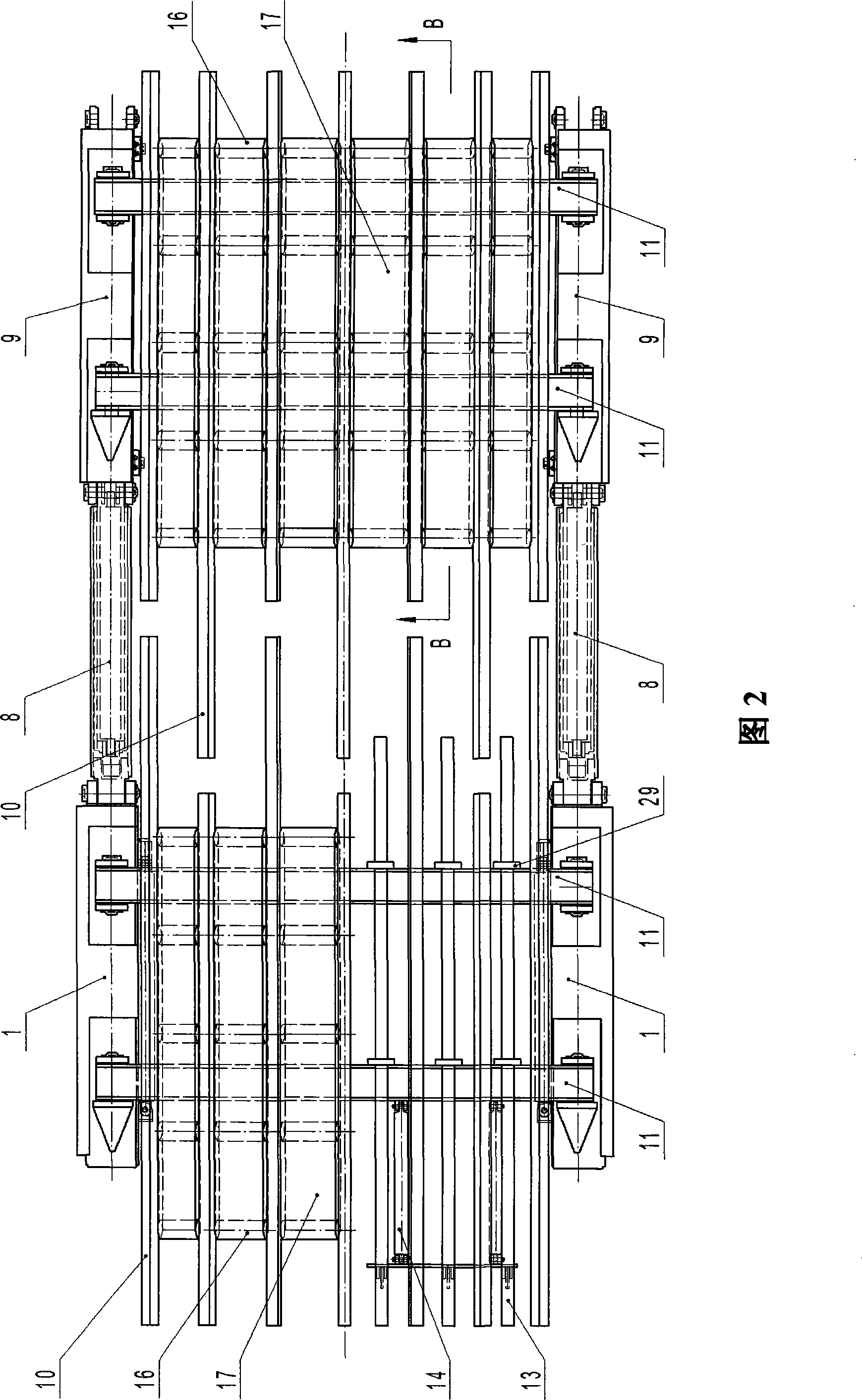

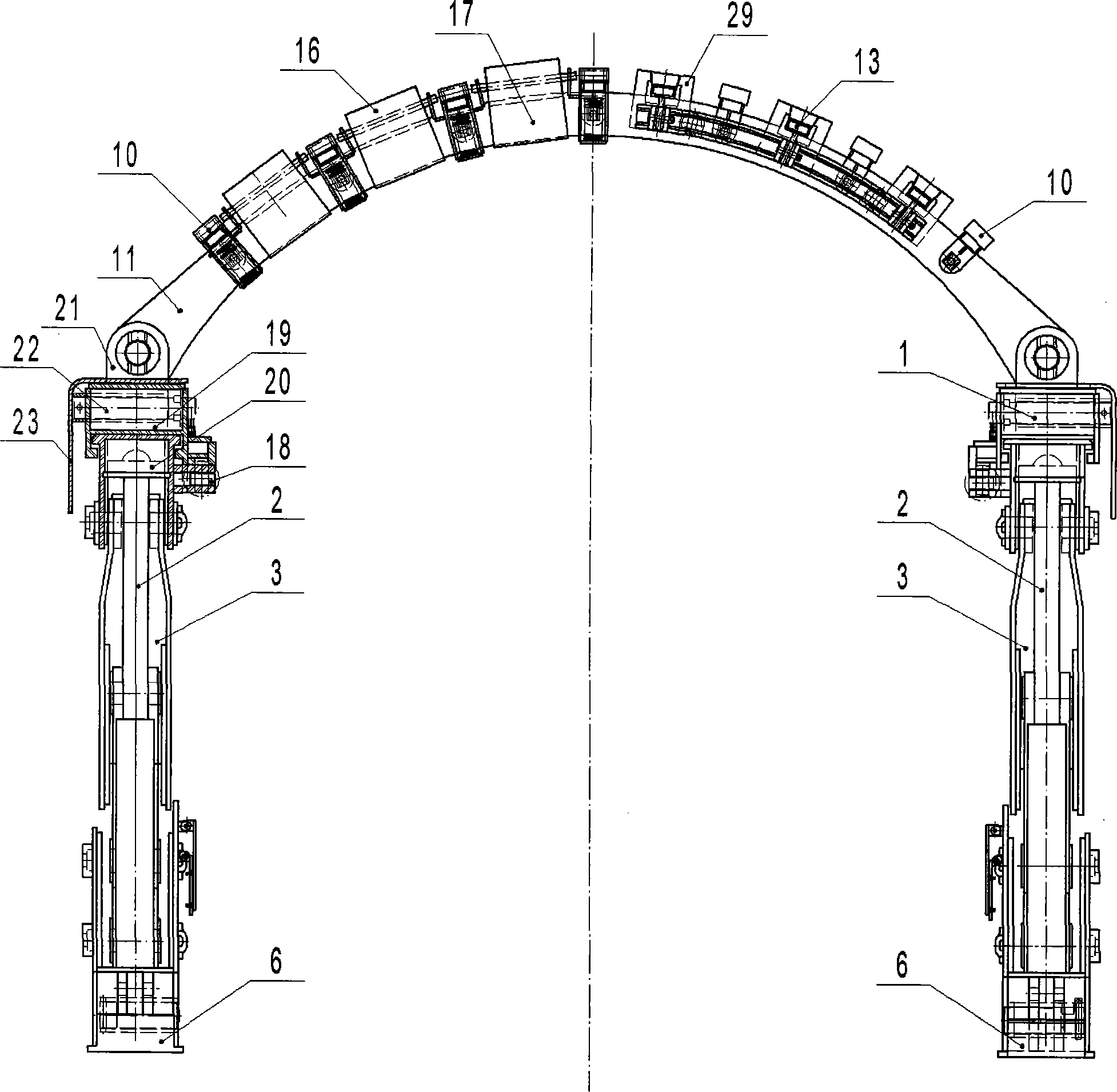

[0023] The specific structure of the present invention will be described in detail with reference to FIGS. 1 to 8 . The timely supporting device of the fully mechanized excavator includes a base 6 whose axes are parallel to each other and in the same plane, a top beam and a hydraulic column 2 connecting the top beam and the base 6, and a side frame composed of a four-bar linkage mechanism, hinged on two The telescopic connecting beam 8 between the side frames and the pushing hydraulic cylinders 15, 7, the front bracket hinged by the single or double row of side frames and the cross beam, the continuous bracket and the following beam 10 assembled on each bracket, the belt guard Beams and telescopic shun beams and other pieces. Wherein used base 6, hydraulic upright column 2 and the four-bar linkage mechanism etc. that are formed by mutually hinged upper link 3, front link 4 and rear link 5, etc., all adopt the common structure of roadway excavation working face. The telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com