Electro-hydraulic control system for working surface hydraulic support

An electro-hydraulic control system and hydraulic support technology, which is applied in mine roof support, mining equipment, earth square drilling and mining, etc., to achieve the effects of cost reduction, novel layout, and convenient memory and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be explained in detail below in conjunction with the drawings.

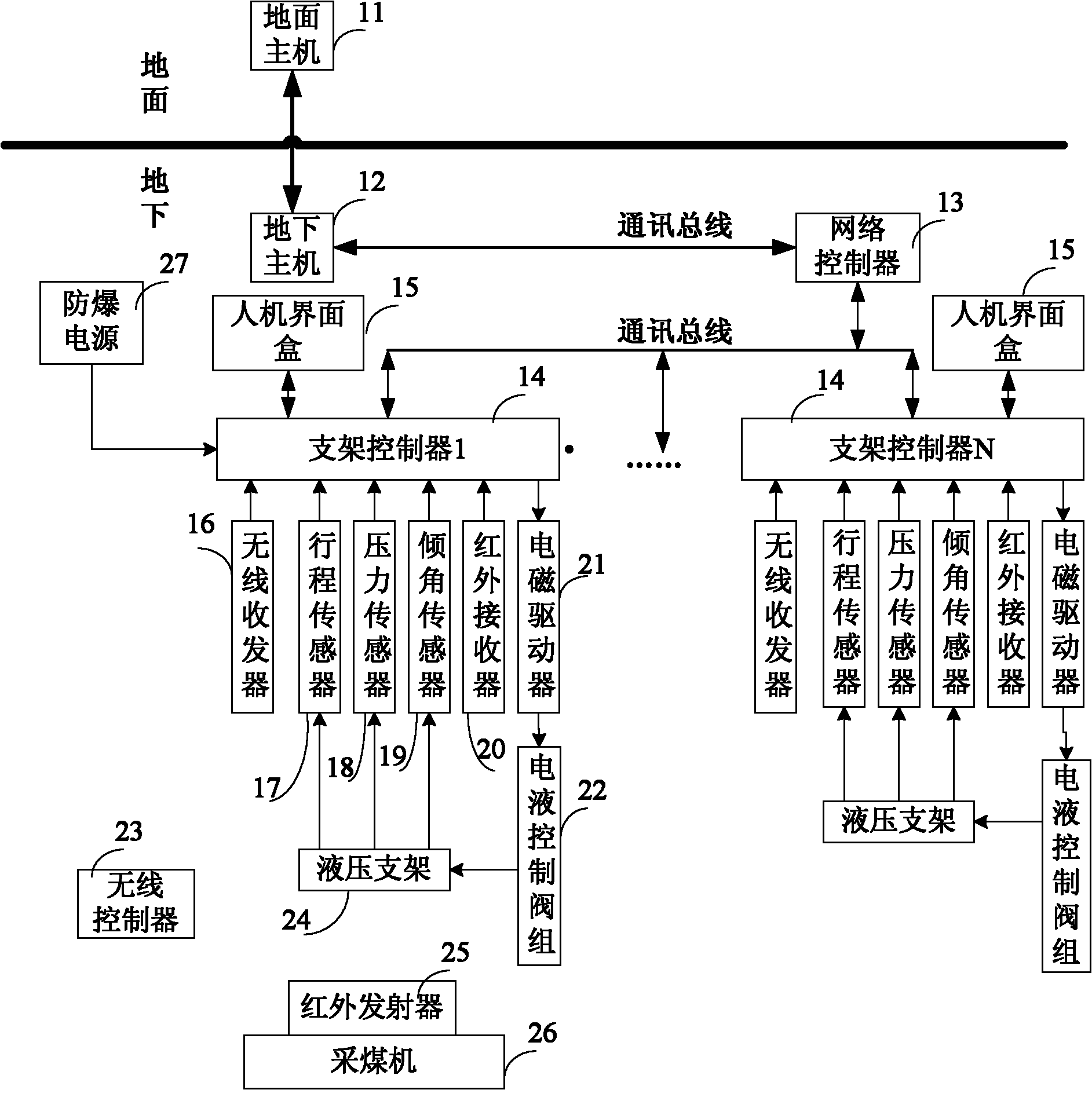

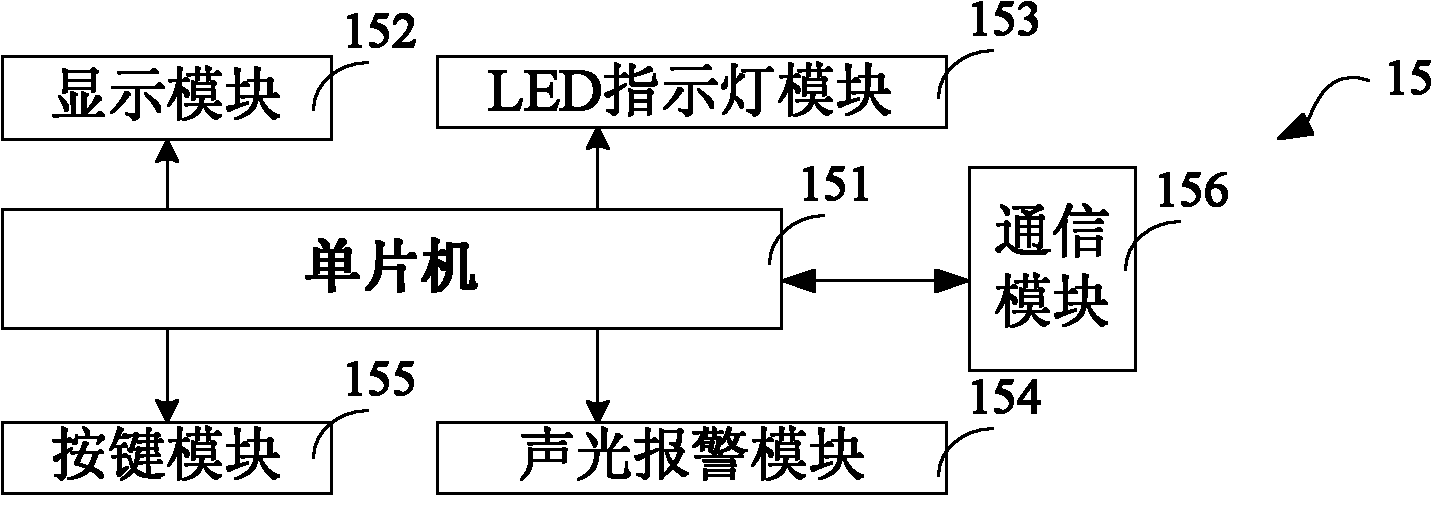

[0045] Such as figure 1 Shows the electro-hydraulic control system of the working face hydraulic support of the present invention, including a ground host 11, an underground host 12, a network controller 13, and at least one support controller 14 connected through a communication bus, and a man-machine interface connected to the support controller 14 Box 15, wireless transceiver 16, stroke sensor 17, pressure sensor 18, tilt sensor 19, infrared receiver 20 and electromagnetic driver 21, and electro-hydraulic control valve group 22 connected to electromagnetic driver 21. The wireless transceiver 16 communicates with the wireless controller in a wireless manner, including downloading an updated program area through wireless communication to update the program in the cradle controller 14. The stroke sensor 17, the pressure sensor 18, the inclination sensor 19 and the electro-hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com